IOUT

mEZDPD4506AS

mEZDPD4506AS 是一款可配置的 DC/DC 降压电源模块,输出电流最高可达 6A ,输出电压范围为 3.5-45V。 该模块具有可多次编程的存储器,并可以通过简单的 GUI (图形用户界面) 进行编程。 采用易用的 10mmx10mmx4mm QFN 封装。

需要配置不同的 VIN, IOUT 吗 ?

Session textval

Session Titefor popup

Generating Custom Datasheet

Waveforms of Your Custom Specs

- Start Up

- Steady State

- Load Transient

- Vin Shutdown

- SCP

- Line Transient

- Bode Plot

- Efficiency

- BOM

| 第一步: | 输入定制规格参数并查看定制规格书 |

|

|||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 第二步: | 保存设计至您的账户 | ||||||||||||||||||||||||||||||||

| 第三步: | 购买您定制的评估板或模块,7天即可交货 | ||||||||||||||||||||||||||||||||

Vo pk-pk: mV @ △Io= A with slew rate 1.6V/us

Target Efficiency: %

Load Current= Efficiency= Power Loss=

Time= Vsw= Vin= Vo= IL= PG= Io=

| Result: | Bandwidth: kHz | Phase Margin: degree |

|

Select a Performance Characteristic to See Results.

| Vin: | V | |

| Io: | A |

| Vin: | V | |

| Io: | A |

| Vin: | V | |

| Io: | A |

| Low Current: | A | |

| High Current: | A | |

| Vin: | V | |

| Vin: | V |

| Low Voltage: | V | |

| High Voltage: | V | |

| Io: | A | |

Notes: For detailed circuit, including the BOM of mEZDPD4506AS, please see the datasheet. Powered by module MPM3596 which includes IC# DIY8886.

Virtual Bench Summary mEZDPD4506AS

html2canvas

html2canvas

Forced CCM

Hiccup

Latch

Hiccup

Ignore

Latch

Ignore

Latch

Custom Design

Note: Save design to assign PN

Design Name

PRELIMINARY SPECIFICATIONS SUBJECT TO DESIGN FINALIZATION

DESCRIPTION

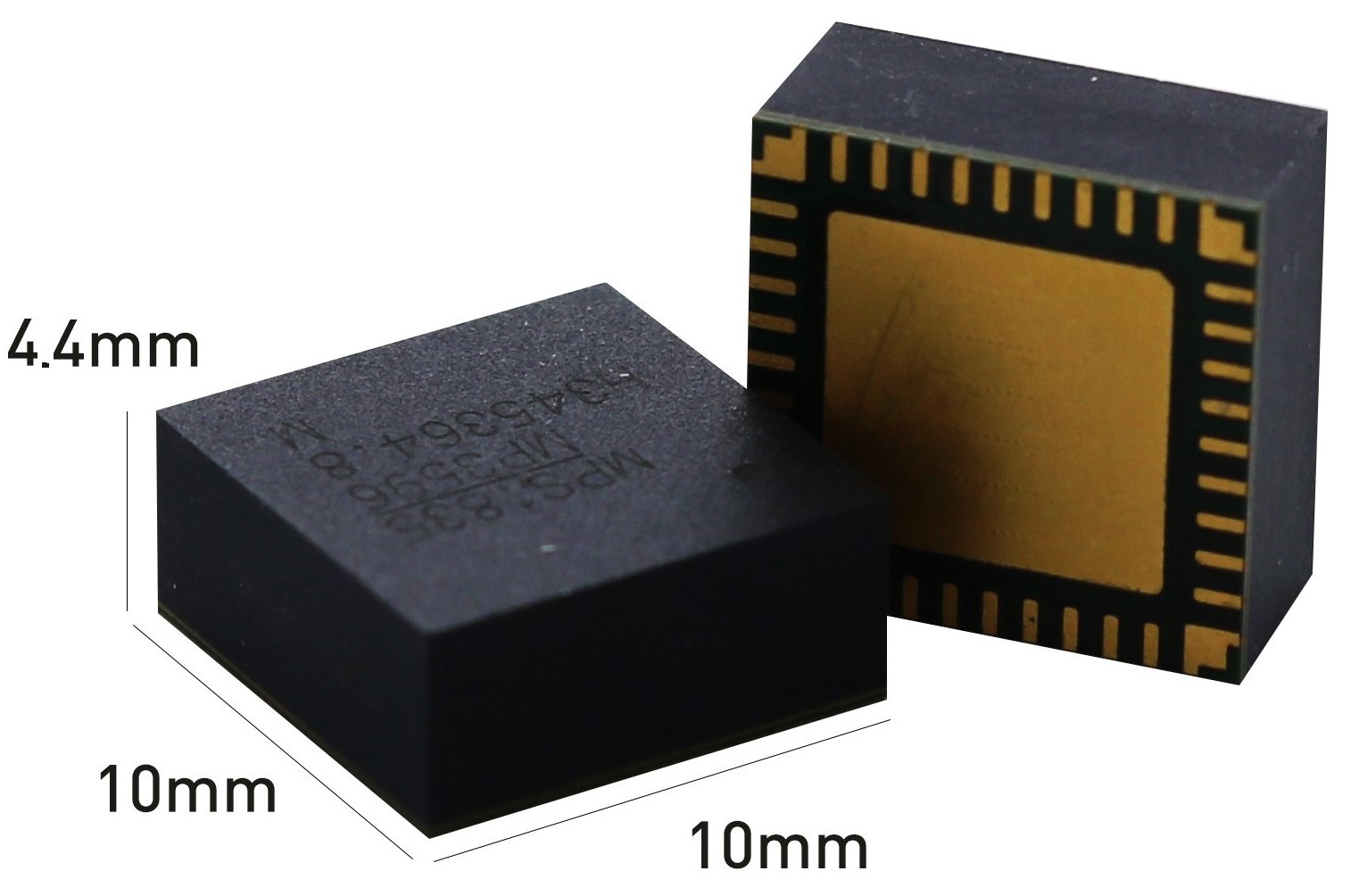

This device is a dual-phase, high-frequency, synchronous, stepdown power module with a PMBus control interface and configured for single output. It integrates internal high-side and low-side power MOSFETS and inductor with high efficiency, and is available in a LGA45 (10mmx10mmx4.4mm) package. With internal compensation network, this device offers a compact solution with a minimal standard external components.

SPECIFICATION OVERVIEW

VOUT

Typical VIN

VIN Min

VIN Max

FEATURES

- Telemetry Readback Includes VIN, VOUT, IOUT, Temperature, and Faults

- Noise-Cancelling, Dual-Side Input Capacitors and Frequency Spread Spectrum Option for Low EMI

- Power Good and Fault Indication

- Output Over-Voltage, Under-Voltage, Over-Current, and Over-Temperature Protection

- 1% VOUT Accuracy Over Operation Temperature Range

- Available in an LGA-45 (10mmx10mmx4.4mm) Package

EFFICIENCY

VIN = , VOUT = , IOUT =

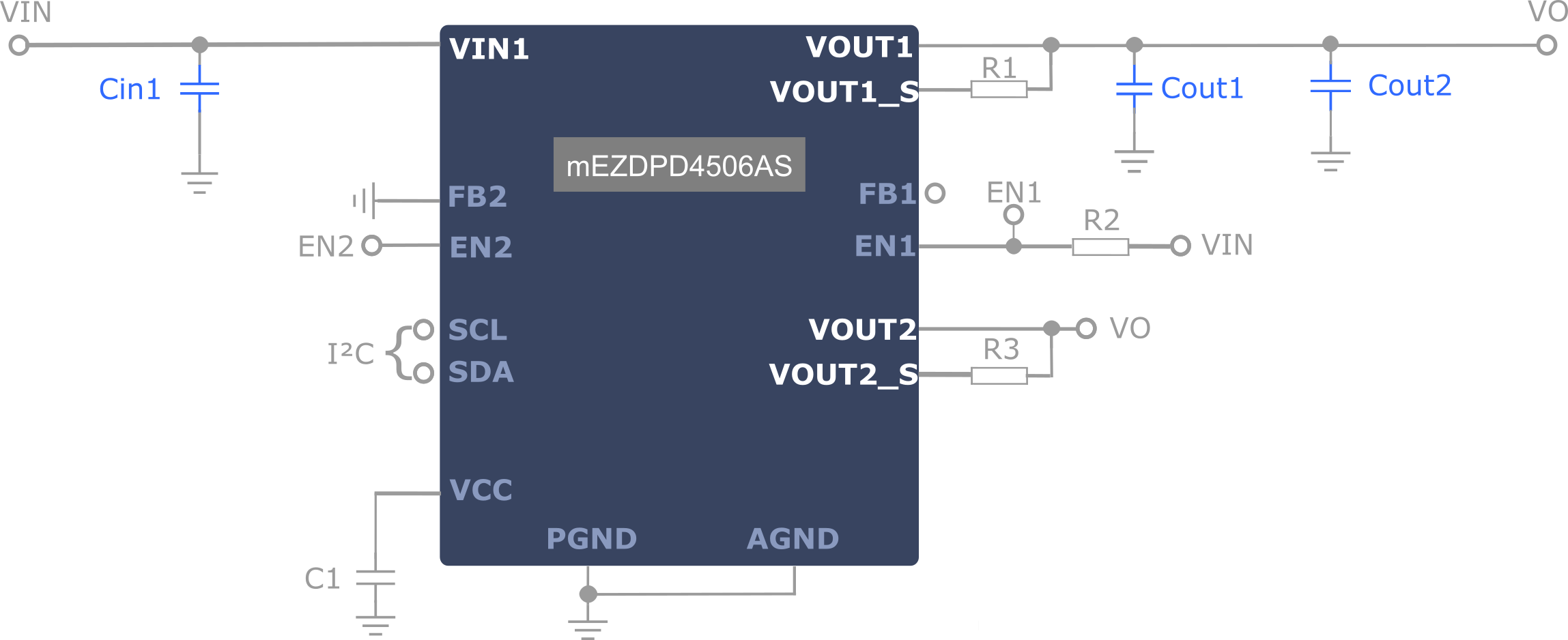

TYPICAL APPLICATION

BOM

Reference

Quantity

Value

Description

Package

Manufacturer

Part Number

Cin1

Cout1

Cout2

R2

1

499kΩ

Film Res, 1%

'0402'

R1

1

10Ω

Film Res, 1%

'0402'

R3

1

10Ω

Film Res, 1%

'0402'

C1

1

1uF

Cap, Ceramic, 10V, X5R

'0402'

U1

1

-

Programmable 45V DC/DC Power

module supply up to 6A

'LGA

(10x10x4.4mm)'

MPS

ORDERING INFORMATION

Part Number

Finalize Design to Order

PACKAGE REFERENCE

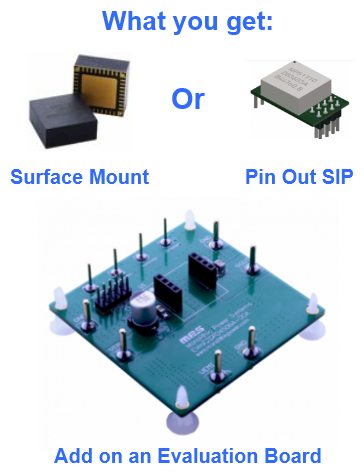

OTHER ORDERING OPTIONS

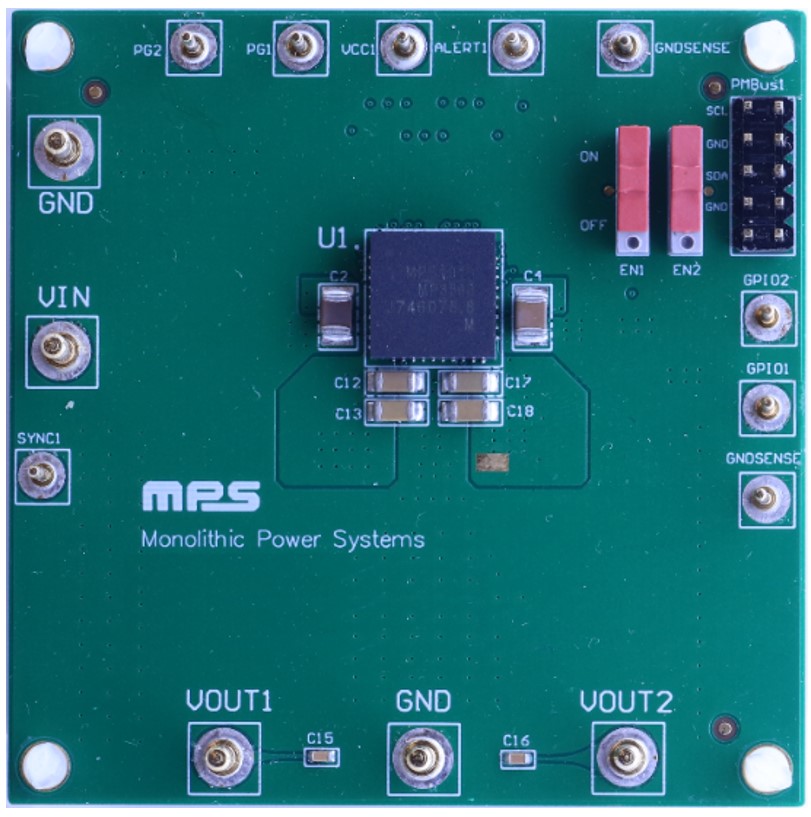

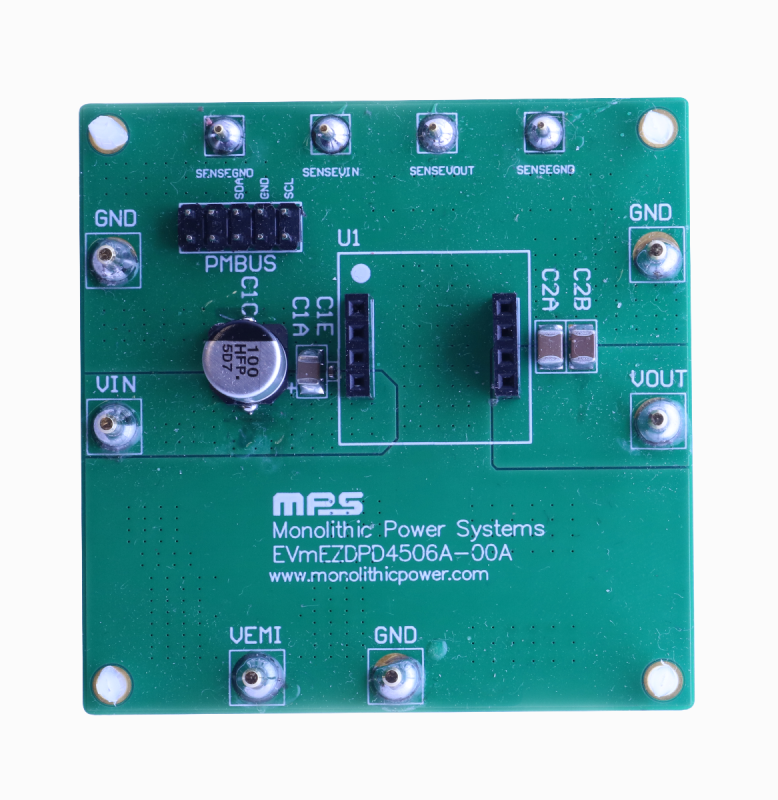

Evaluation Board for Surface Mount Device

The evaluation board is designed to demonstrate the capabilities of your custom MPS Custom PN.

The EVB device is programmed with custom configuration.

Part Number

EVmEZDPD4506AS-00A

DIP Mount (Pin Out Version)

The Custom PN is your custom device on a DIP mount for an easy-to-use, plug-and-play form factor.

The pin out module device is programmed with custom configuration.

Part Number

mEZDPD4506A

Socket Evaluation Board for DIP Mount

DIP mount socket only. For easy evaluation of pin out module.

Part Number

EVmEZDPD4506A-00A

All EVB schematic and layout files can be found at:

https://www.monolithicpower.com/mezdpd4506as.html

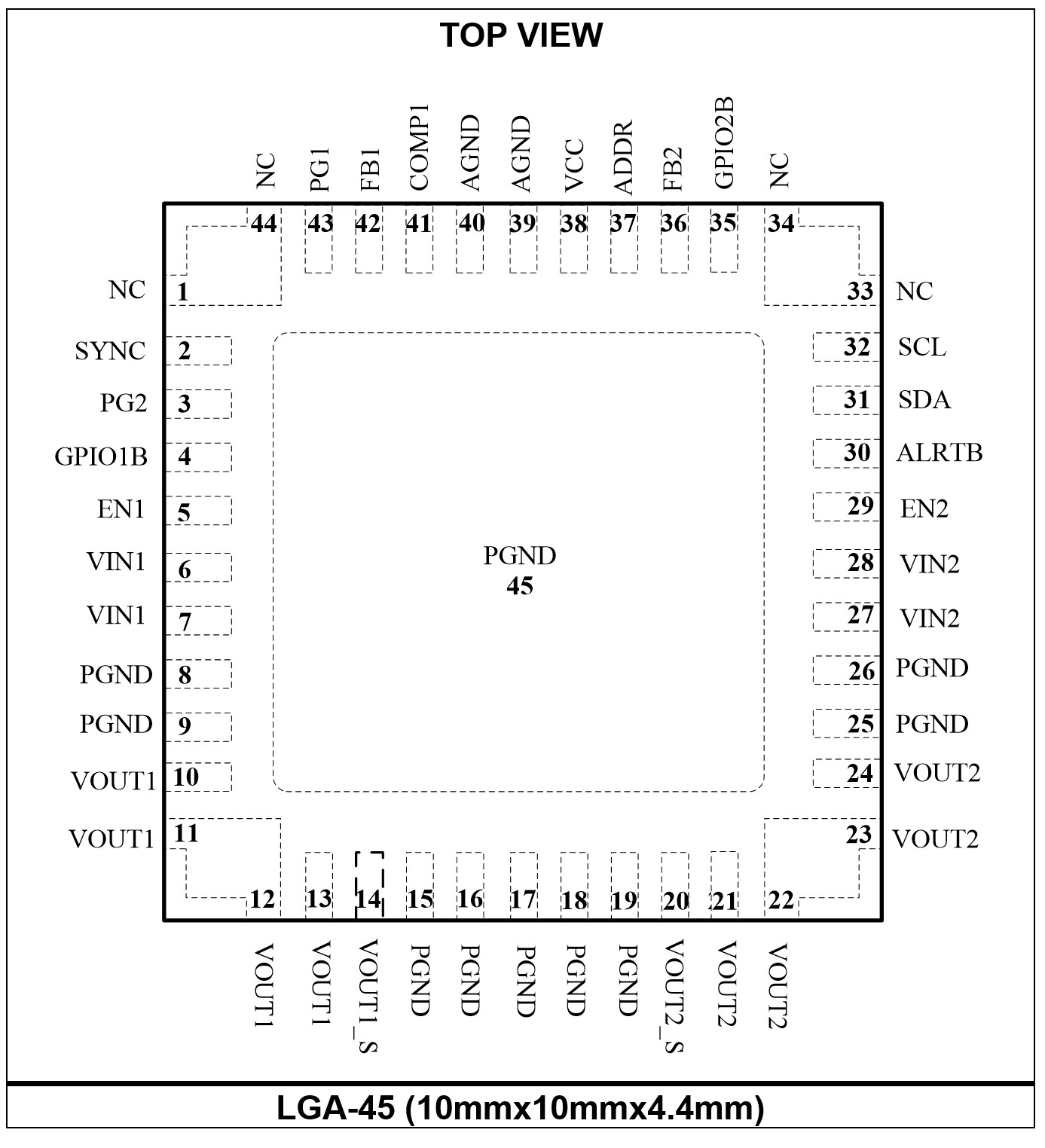

PIN FUNCTIONS

Pin #

Name

Description

1, 33, 34, 44

NC

No connection.

2

SYNC

Synchronized to external clock signal. Can be programmed by PMBus to sync input or sync output.

3

PG2

Power good indicator for channel 2. The output of PG is an open drain. Connect a resistor to a pull-up power source if used.

4

GPIO1B

General I/O port 1.

5

EN1

Enable 1 pin. Drive EN1 high to turn on channel 1, and drive it low or float it to turn off the device. It has an internal, 1MΩ, pull-down resistor to ground.

6, 7

VIN1

Channel 1 supply voltage. This pin supplies all power to the converter. Place a decoupling capacitor to ground as close as possible to the IC to reduce switching spikes. Connect using a wide PCB trace.

8, 9, 15, 16, 17, 18, 19, 25, 26

PGND

Power ground. Reference ground of the regulated output voltage. Connect these pins to large copper areas to the negative terminals of the input and output capacitors.

10, 11, 12, 13

VOUT1

Channel 1 power output. Connect load to VOUT1. An output capacitor is needed.

14

VOUT1_S

Channel 1 power output sense input. Connect directly to VOUT1.

20

VOUT2_S

Channel 2 power output sense input. Connect to VOUT2 directly.

21, 22, 23, 24

VOUT2

Channel 2 power output. Connect load to VOUT2. An output capacitor is needed.

27, 28

VIN2

Channel 2 supply voltage. This pin supplies all power to the converter. Place a decoupling capacitor to ground as close as possible to the IC to reduce switching spikes. Connect using a wide PCB trace.

29

EN2

Enable 2 pin. Drive EN2 high to turn on channel 2, and drive it low or float it to turn off the device. It has an internal, 1MΩ, pull-down resistor to ground.

30

/ALERTB

PMBus alert.

31

SDA

PMBus serial data.

32

SCL

PMBus serial clock.

35

GPIO2B

General I/O port 2.

36

FB2

Error amplifier feedback inputs for channel 2. This pin receives sensed voltage feedback voltage for channel 2 from an external resistive divider across the output. In multi-phase mode, this pin must be pulled up high to disable this channel’s error amplifier.

37

ADDR

Address setting for the PMBus.

38

VCC

Internal 5V LDO regulator output. Decouple with a 0.22µF capacitor.

39, 40

AGND

Signal ground. Ground for internal logic and signal circuit. AGND is not internally connected to power ground. Be sure to connect AGND to power ground in PCB layout.

41

COMP1

Channel 1 error amplifier output. For multi-chip, multi-phase applications, connect this pin for each chip for current sharing.

42

FB1

Error amplifier feedback inputs for channel 1. This pin receives sensed voltage feedback voltage for channel 1 from an external resistive divider across the output.

43

PG1

Power good indicator for channel 1. The output of PG is an open drain. If used, connect a resistor to a pull-up power source.

ABSOLUTE MAXIMUM RATINGS

(1)VIN

-0.3V to +48V

VEN

-0.3V to +45V

All other pins

-0.3V to +6V

Continuous power dissipation (TA = 25°C) LGA-45 (10mmx10mmx4.4mm) (2)

TBD

Junction temperature

150°C

Lead temperature

260°C

Storage temperature

-65°C to +150°C

Supply voltage (VIN)

3.5V to 45V

Output voltage (VOUT)

0.6V to 22V

Operation junction temp (TJ)

-40°C to +125°C

Thermal Resistance (3)

θJA

θJC

LAG-45 (10mmx10mmx4.4mm)

TBD

TBD °C/W

- 1) Exceeding these ratings may damage the device.

- 2) The maximum allowable power dissipation is a function of the maximum junction temperature TJ (MAX), the junction-to-ambient thermal resistance θJA, and the ambient temperature TA. The maximum allowable continuous power dissipation at any ambient temperature is calculated by PD (MAX) = (TJ (MAX) - TA) / θJA. Exceeding the maximum allowable power dissipation will cause excessive die temperature, and the regulator will go into thermal shutdown. Internal thermal shutdown circuitry protects the device from permanent damage.

- 3) Measured on JESD51-7, 4-layer PCB.

PROGRAMMABLE ELECTRICAL CHARACTERISTICS

Parameter

Symbol

Description

Min

Typ

Max

Units

Under-Voltage Lockout (UVLO)

VIN UVLO rising threshold

VINUVVTH RISE

Programmed value, device powered on voltage assuming that EN is active

V

VIN UVLO falling threshold

VINUVVTH FALL

Programmed value, device powered off voltage assuming that EN is active

V

VIN UVLO hysteresis

VINUVHYS

Programmed value, VINUVVTH RISE - VINUVVTH FALL

V

EN voltage hysteresis

VEN HYS

Programmed value

mV

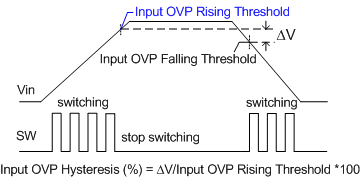

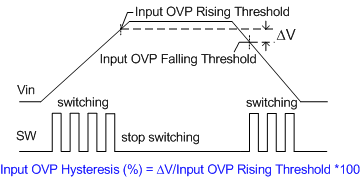

Input Over-Voltage Protection

Input OVP threshold

VINOVP TH

Programmed value, threshold for input over-voltage fault detection

V

Input OVP hysteresis

VINOVP HYS

Programmed value

mV

Input OVP retry interval

Programmed value, restart interval time after triggering input over-voltage fault

ms

Output Voltage

Operation V

V

Programmed value, set value of output voltage

V

Voltage feedback divider range

Programmed value, sets the internal voltage divider ratio

Output voltage margin high

VOUT MARGIN HIGH

Programmed value, output voltage high margin

V

Output voltage margin low

VOUT MARGIN LOW

Programmed value, output voltage low margin

V

Output voltage max

VOUT MAX

Programmed value, upper limit on the output voltage the converter can command regardless of any other commands or combinations

V

Output voltage transition rates

Programmed value, VOUT changing slew-rate control bits, this control only works after SS finishes and during the SS period, the VOUT slew rate is controlled by the SS pin

V/ms

Switching

Switching frequency

fSW

Programmed value, the set value of the switching frequency

kHz

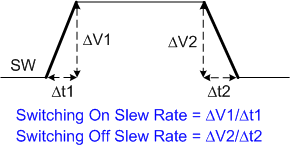

Switching on slew rate (5)

Programmed value, switching rising slew rate

V/ns

Switching off slew rate (5)

Programmed value, switching falling slew rate

V/ns

Dithering cycle

Programmed value, frequency of dithering

kHz

Dithering range

Programmed value

kHz

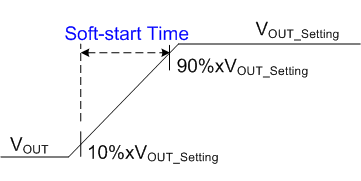

Soft Start

Soft-start time

tSS

Programmed value, time from the moment when the output starts to rise to when the output voltage reaches the regulation point

ms

tON delay

tON_DELAY

Programmed value, the time from the moment EN turns on to when the output voltage starts rising

ms

tOFF fall

tOFF_FALL

Programmed value, the time from when the output starts to fall until the voltage reaches the zero point

ms

tOFF delay

tOFF_DELAY

Programmed value, the time from the moment EN turns off to when the output starts to fall

ms

Light-Load Mode

AAM threshold for extending frequency

Programmed value, extending frequency if the inductor peak current is below this threshold

mA

AAM threshold for blanking clock

Programmed value, blanking the internal clock if the inductor peak current is below this threshold

mA

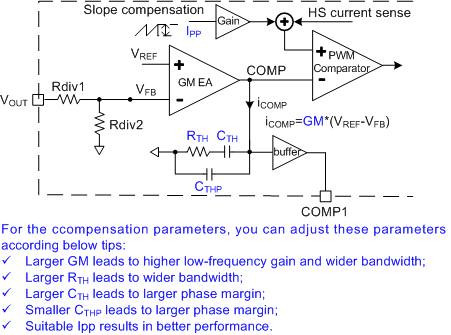

Compensation

Compensation RTH

RTH

Programmed value, compensation resistor RTH

kΩ

Compensation CTH

CTH

Programmed value, compensation capacitor CTH

pF

Compensation CTHP

CTHP

Programmed value, compensation capacitor CTHP

pF

Compensation Slope

Programmed value, slope compensation amplitude

A

Compensation GM

GM

Programmed value, transconductance of the error amplifier

μA/V

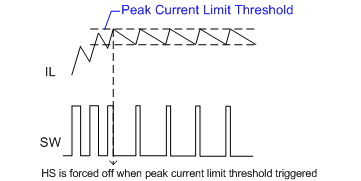

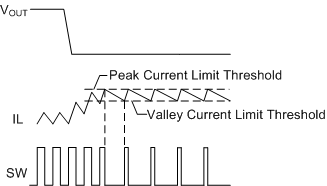

Over-Current Protection

Peak current limit

IPEAK-LIMIT

Programmed value, threshold of the inductor peak current limit

A

Valley current limit

IVALLEY-LIMIT

Programmed value, threshold of the inductor valley current limit

A

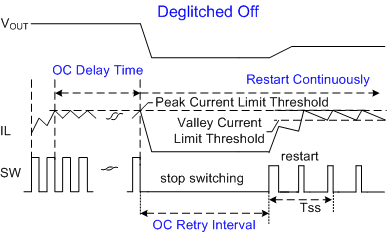

Over-current retry interval

Programmed value, restart interval time after triggering over-current fault and shutdown

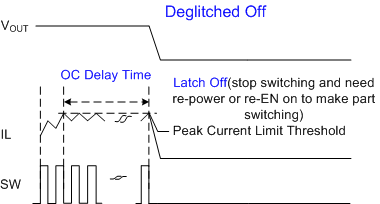

ms

Over-current delay time

Programmed value, device response delay time when output over-current fault is triggered

μs

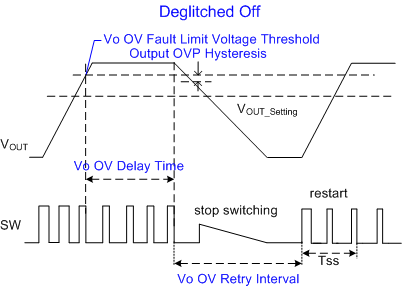

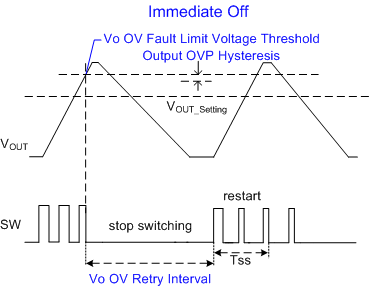

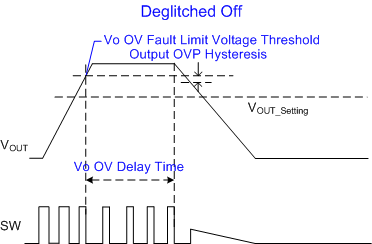

Output Over-Voltage and Under-Voltage Protection

Output Over-Voltage and Under-Voltage Protection

VOVP_TH

Programmed value, threshold for output over-voltage fault detection, as percentage of VOUT set

%

Output OVP hysteresis

VOVP_HYS

Programmed value, as percentage of VOUT set

%

Output OVP retry interval

Programmed value, restart interval time after triggering output over-voltage fault and shutdown

ms

Output OVP delay time

Programmed value, device response delay time when output over-voltage fault is triggered

μs

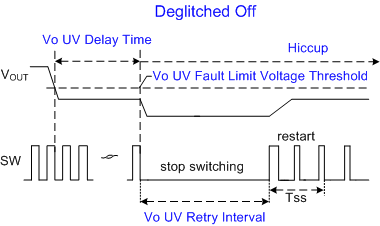

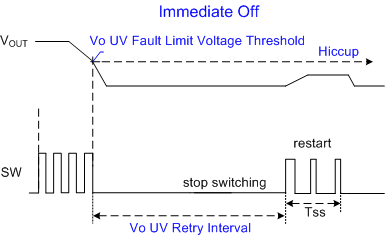

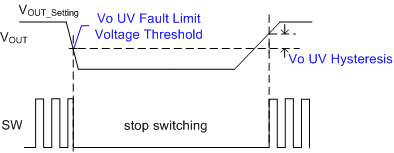

Output UVP threshold

VUVP_TH

Programmed value, threshold for output under-voltage fault detection, as percentage of VOUT set

%

Output UVP hysteresis

VUVP_HYS

Programmed value, as percentage of VOUT set

%

Output UVP retry interval

Programmed value, restart interval time after triggering output under-voltage fault and shutdown

ms

Output UVP delay time

Programmed value, device response delay time when output under-voltage fault is triggered

μs

Thermal Protection

Thermal shutdown (5)

TSD

Programmed value, threshold for thermal over-temperature fault detection

°C

Thermal shutdown hysteresis (5)

TSD_HYS

Programmed value

°C

Note:

5) Not tested in production. Guaranteed by design and characterization.

PROGRAM OPERATION SETTINGS

Name

Selected Mode

Description

Note

Output Voltage

Output voltage set mode

0: Use external voltage divider

1: I2C programmable mode

Output voltage bias enable

0: Disable

1: Enable

Switching

Switching dithering Enable/Disable

Frequency dither function enable bit.

0: Disable

1: Enable

Light-Load Mode

Light-load mode

0: AAM

1: CCM

Input Over-Voltage Protection

Input OVP mode

00: Ignore. The device will operate without interruption.

01: Not supported.

10: Immediate off. The device will shut down immediately, and responds according to the Input OVP Retry Settings

Input OVP retry settings

0: No restart

1: Restart continuously

Over-Current Protection

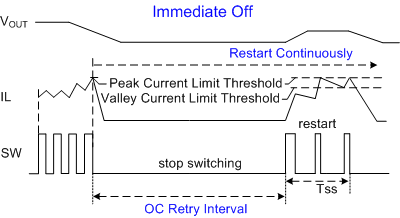

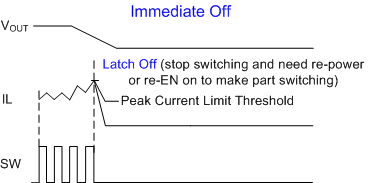

Over-current response

00: Current limit only

01: Deglitched off

10: Immediate off

Over-current retry settings

0: Latch off

1: Restart continuously

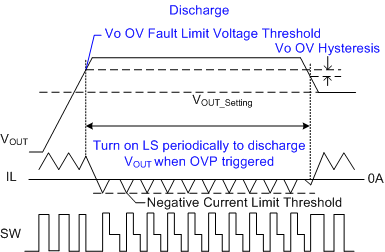

Output Over-Voltage and Under-Voltage Protection

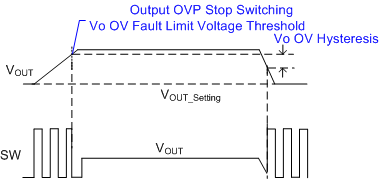

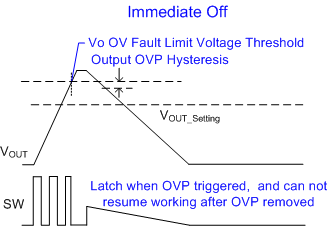

Output OVP mode

00: Ignore

01: Deglitched off

10: Immediate off

11: Discharge mode

Output OV retry settings

0: Latch off

1: Restart continuously

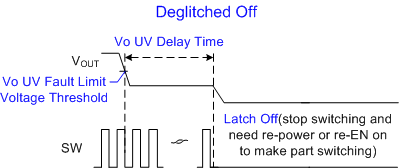

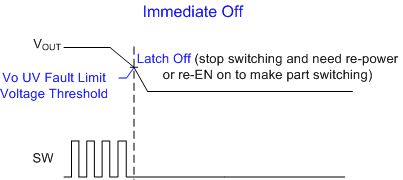

Output UVP mode

00: Ignore 01: Deglitched off 10: Immediate off

Output UVP retry settings

0: Latch off

1: Hiccup mode

SYNC IN/OUT

0: SYNC OUT

1: SYNC IN

Power Stage Set

Power stage select

1: Set from MTP

Power stage

001: Dual-phase single output operation

10: Two-chip, 4-phase, 12A operation (master1)

101: Two-chip, 4-phase, 12A operation (master2)

011: Two-chip, 4-phase, 12A operation (slave1)

111: Dual-output buck operation

Rail Address

Enable rail address

0: Disable

1: Enable

Address

Rail Address

GPIO

Input over-voltage

Input over-voltage indication setting

0: Disable

1: Enable

Over-temperature

Over-temperature indication setting

0: Disable

1: Enable

Output under-voltage

Output under-voltage indication setting

0: Disable

1: Enable

Over-voltage

Over-voltage indication setting

0: Disable

1: Enable

Over-current

Over-current indication setting

0: Disable

1: Enable

GPIO mode

GPIO mode set

0: Analog input

1: Digital output

Operation

Operation

80: ON

40: Soft off

00: Immediate off

94: Margin low

A8: Margin high

ELECTRICAL CHARACTERISTICS

VIN = 12V, VEN = 2V, TA= -40°C to +125°C, typical value is tested at TJ = 25°C, unless otherwise noted.

Parameter

Symbol

Condition

Min

Typ

Max

Units

VIN quiescent current

IQ

VOUT = 3.3V, with BIAS power, no load

12

µA

IQ

VFB > VREF, no load

TBD

μA

VIN shutdown current

ISD

VEN = 0V, TJ =25°C

1

μA

Sync frequency range

fSYNC

Sync clock set range

150

2200

kHz

Sync voltage high threshold

VSYNC_HIGH

1.4

1.8

V

Sync voltage low threshold

VSYNC_LOW

0.4

0.8

V

Minimum on time (5)

tON_MIN

With peak current mode

100

ns

Minimum off time (5)

tOFF_MIN

130

ns

HS switch on resistance

RDSON_H

VBST - VSW = 5V

62

mΩ

LS switch on resistance

RDSON_L

34

mΩ

Integrated inductor inductance

L1

3.3

µH

L2

3.3

µH

Inductor DC resistance

L1_DCR

26

mΩ

L2_DCR

26

mΩ

Switch leakage current

ISW_LKG

TJ = 25°C

1

µA

Default EN voltage threshold

VEN

PMBus default set

1

1.2

1.4

V

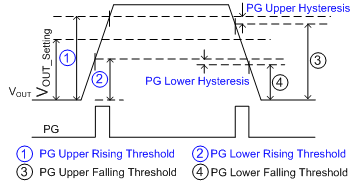

PG upper trip threshold

Programmed value, as percentage of VOUT set, equal to VOVP_TH

%

PG upper trip hysteresis

As percentage of VOUT set, equal to VOVP_HYS

%

PG lower trip threshold

As percentage of VOUT set, equal to VUVP_TH

%

PG lower trip hysteresis

As percentage of VOUT set, equal to VUVP_HYS

%

PG output voltage low

VPG_SINK

ISINK = 1mA

0.1

0.3

V

PG deglitch timer

tPG_DELAY

20

µs

VCC regulator

VCC

ICC = 0mA

4.7

4.9

5.1

V

Input OVP threshold accuracy

PMBus set 36V

34

36

38

V

Note:

5) Not tested in production. Guaranteed by design and characterization.

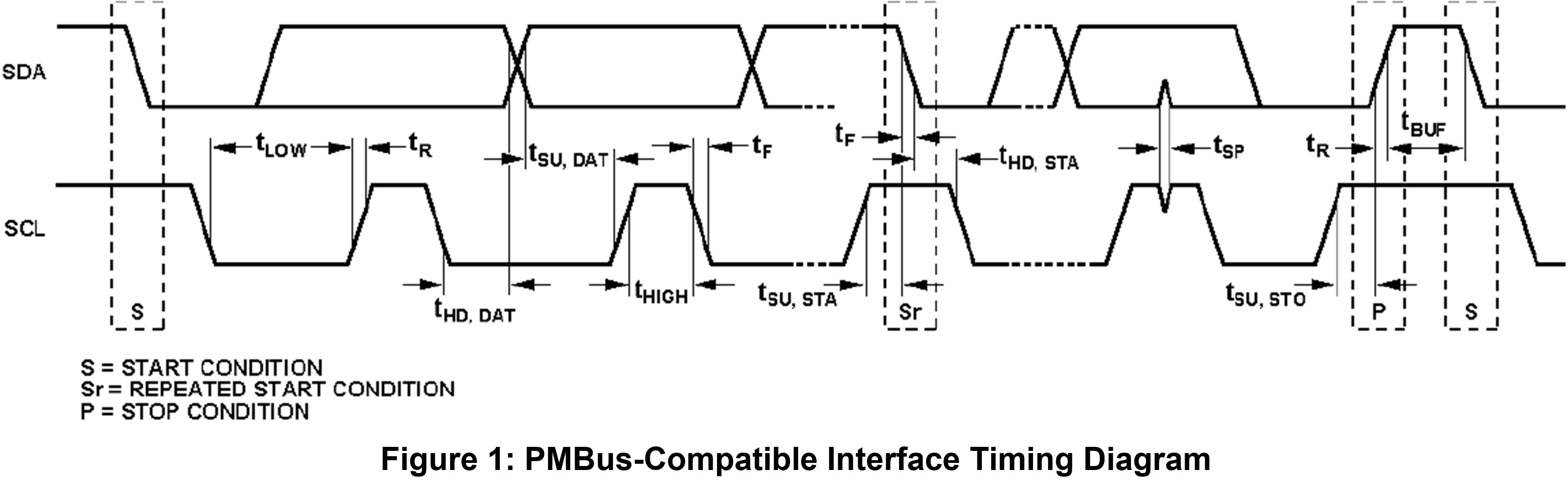

PMBUS PORT SIGNAL CHARACTERISTICS

VIN = 12V, VEN = 2V, TA = -40°C to +125°C, typical values tested at TJ = 25°C, unless otherwise noted.

Parameters

Symbol

Condition

Min

Typ

Max

Units

PMBus Interface Specifications

Input logic low

VIL

0

0.4

V

Input logic high

VIH

1.3

V

Output logic low

VOL

ILOAD = 3mA

0.4

V

SCL clock frequency

fSCL

400

kHz

SCL high time

tHIGH

0.6

μs

SCL low time

tLOW

1.3

μs

Data set-up time

tSU,DAT

100

ns

Data hold time

tHD,DAT

0

0.9

μs

Set-up time for repeated start

tSU,STA

0.6

μs

Hold time for start

tHD,STA

0.6

μs

Bus free time between a start and a stop condition

tBUF

1.3

μs

Set-up time for stop condition

tSU,STO

0.6

μs

Rise time of SCL and SDA

tR

20 + 0.1 × CB

120

ns

Fall time of SCL and SDA

tF

20 + 0.1 × CB

120

ns

Pulse width of suppressed spike

tSP

0

50

ns

Capacitance bus for each bus line

CB

400

pF

TYPICAL PERFORMANCE CHARACTERISTICS

All waveforms simuated.

EFFICIENCY

VIN = , VOUT = , IOUT =

LINE TRANSIENT

Vlow = , Vhigh = , Iout = , Slew rate =

START-UP

VIN = , IOUT =

VIN SHUTDOWN

VIN = , IOUT =

STEADY STATE RIPPLE

VIN = , IOUT =

LOAD TRANSIENT

VIN = , IHIGH = , ILOW = , Slew Rate =

SCP

VIN =

BODE PLOT

Bandwith = , Phase Margin = , Gain Margin =

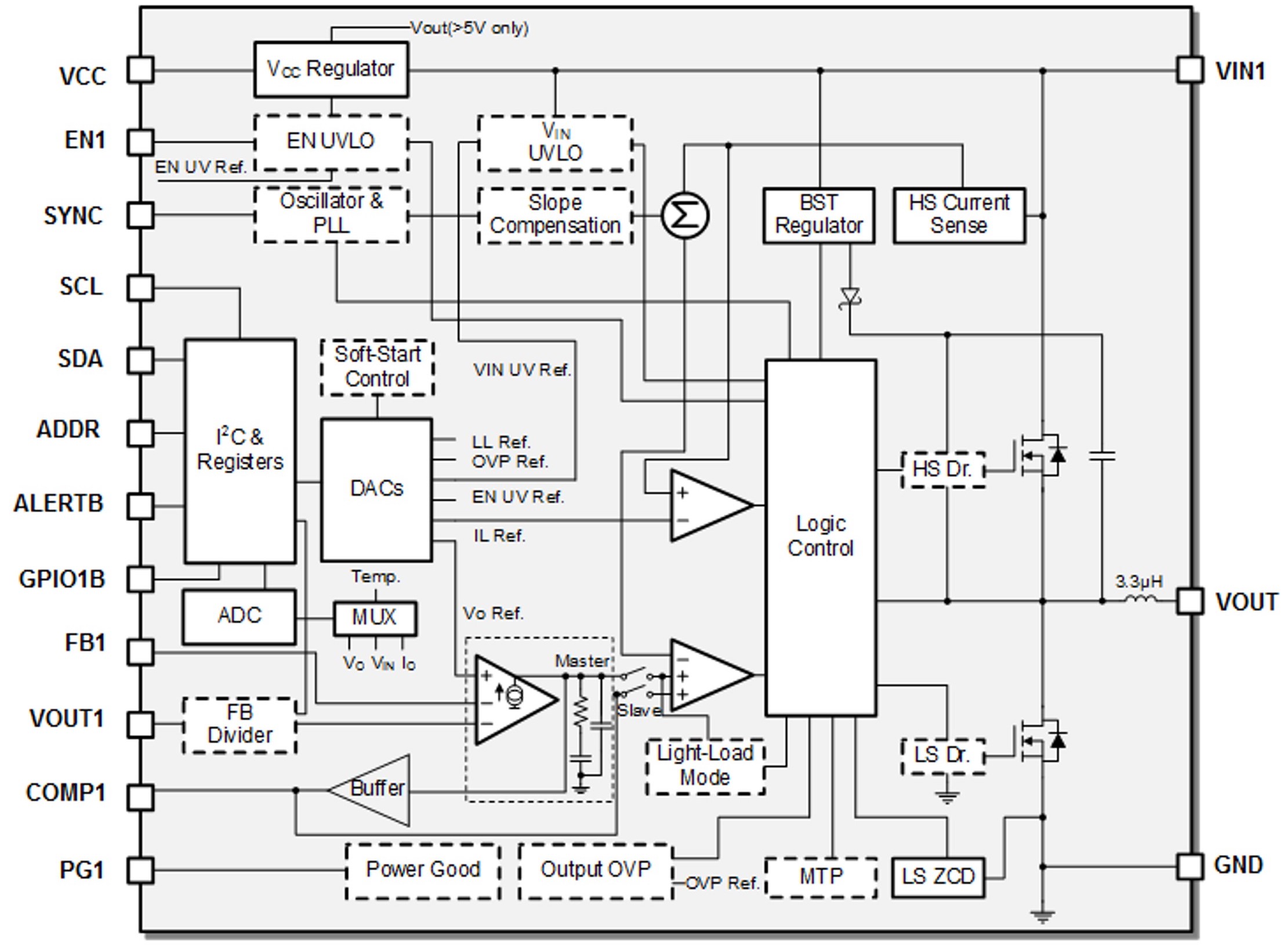

FUNCTIONAL BLOCK DIAGRAM

Figure 2: Functional Block Diagram

(Only one channel is shown, blocks in dashed line are programmable via the PMBus)

OPERATION

This device is a high-frequency, synchronous, step-down converter with built-in power MOSFETs. Figure 2 shows a block diagram of the part. It is available with a wide 3.3V to 45V input supply range, and can achieve up to 3A continuous output current per phase, or parallel for 6A total output current. It can also be paralleled for 4-phase and 6-phase operation. The device offers excellent load and line regulation over an ambient temperature range of -40°C to +125°C.

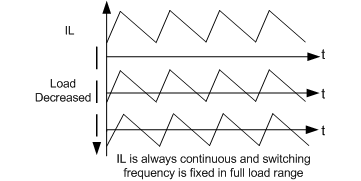

PWM Control

At moderate to high output current, the device operates in a fixed-frequency, peak current control mode to regulate the output voltage. An internal clock initiates a pulse-width modulation (PWM) cycle. At the rising edge of the clock, the high-side switch (HS-FET) turns on, and the inductor current rises linearly to provide energy to the load. The HS-FET remains on until its current reaches the COMP voltage, which is the output of the internal error amplifier. The output voltage of error amplifier depends on the difference of output feedback voltage and the internal high-precision reference, which decides how much energy should be transferred to the load. The higher the load current, the higher the COMP voltage will be. Both the feedback divider ratio and reference can be adjusted by the PMBus, which makes it easy to adjust for different output voltages.

When the HS-FET is off, the low-side switch (LS-FET) turns on immediately and remains on until the next clock cycle starts. During this time, the inductor current flows through the LS-FET. In order to avoid shoot-through, dead time so the HS-FET and LS-FET are not turned on at the same time.

If the current in the HS-FET does not reach COMP set current value in one PWM period, the HS-FET remains on, saving a turn-off operation.

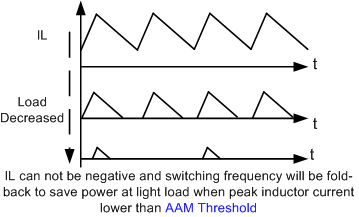

Mode Selection (AAM and Forced CCM)

This device can work in light-load AAM or forced CCM mode, determined by the PMBus. AAM (advanced asynchronous modulation) mode is employed to optimize the efficiency during light-load or no-load conditions. Forced CCM can maintain a constant switching frequency and smaller output ripple, but has low efficiency at light load.

If AAM mode is enabled with load decreasing, the device first enters discontinuous conduction operation (DCM) and maintains a fixed frequency as long as the inductor current approaches zero. If the load is further decreased, or there is no load that makes the inductor peak current lower than the AAM peak current threshold set by the PMBus, the device enters sleep mode and consumes low quiescent current to further improve light-load efficiency. In sleep mode, the internal clock is blocked, and the device skips some pulses. Then the feedback voltage is below the reference, so VCOMP ramps up until the inductor peak current exceeds the AAM threshold. The internal clock resets, and the crossover time is taken as the benchmark of the next clock cycle. This control scheme helps achieve high efficiency by scaling down the frequency to reduce switching and gate driver losses (see Figure 3).

As the output current increases from a light-load condition, VCOMP and the switching frequency increase. If the output current exceeds the critical level set by VCOMP, the device resumes fixed-frequency PWM control.

When forced CCM is enabled, the device operates in a fixed-frequency peak current control mode to regulate the output voltage, regardless of the output current.

Figure 3: AAM and Forced CCM

Internal Regulator

A 5V internal regulator powers most of the internal circuitries. This regulator takes VIN and operates in the full VIN range. When VIN exceeds 5.0V, the output of the regulator is in full regulation. Lower VIN values result in lower output voltages. The regulator is enabled when VIN exceeds its UVLO threshold and EN is high. In EN shutdown mode, the internal VCC regulator is disabled to reduce power dissipation.

For better thermal performance, BIAS mode can be selected by the PMBus. If VOUT is above 5V, VCC and the internal circuit are powered by VOUT.

Enable Control

EN is a digital control pin that turns the regulator, including the PMBus block, on and off. Drive EN high to turn on the regulator; drive it low to turn the regulator off. The EN threshold can be programmed by the PMBus. An internal 5MΩ resistor from EN to GND allows EN to be floated to shut down the chip.

Oscillator Frequency

The default frequency of this device is 500kHz, and it can be programmed from 300kHz to 2.5MHz by the PMBus. The frequency can also be set by a logic-level synchronous signal.

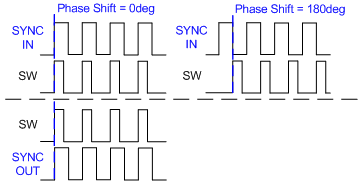

SYNC IN and SYNC OUT

The SYNC pin can be programmed by the PMBus to SYNC IN or SYNC OUT. When operating as SYNC IN, the internal oscillator frequency can be synchronized by an external clock via this pin. At start-up, the device first operates at the internal set frequency, and quickly synchronizes to the external clock once soft start is ready. Ensure the high amplitude of the SYNC clock is above 1.8V and the low amplitude is below 0.4V to drive the internal logic. The recommended external SYNC frequency range is 250kHz to 2.2MHz.

The device operates in forced CCM mode with fixed frequency when there is a SYNC clock, regardless of output current. A pulse longer than 200ns is recommended in application.

When the SYNC pin is set to SYNC OUT, the device outputs the internal clock with a 0° or 180° phase shift. With this function, two devices can operate in same frequency, but 180° out of phase, to reduce the total input current ripple so a smaller input bypass capacitor can be used.

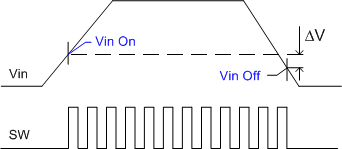

Under-Voltage Lockout (UVLO)

The device has input under-voltage lockout protection (UVLO) to ensure reliable output power. If EN is active, the device is powered on when the input voltage exceeds the UVLO rising threshold, and is powered off when the input voltage drops below the UVLO falling threshold. The UVLO threshold can be set between 3.3V and 5.7V by the PMBus. This function prevents the device from operating at an insufficient voltage. It is a non-latch protection.

Soft-Start

The device has built-in soft start (SS), which ramps up the output voltage at a controlled slew rate when EN goes high, avoiding overshoot during start-up. When the chip starts, the internal circuitry generates a soft-start voltage that ramps up slowly. When the SS voltage (VSS) is below the internal reference (VREF), VSS overrides VREF as the error amplifier reference. When VSS exceeds VREF, VREF acts as the reference. At this point, soft start finishes and the device enters steady-state operation.

The SS time is internally set to 1ms as a default, and can also be set to 0.5ms, 2ms, or 4ms by the PMBus. When the output voltage shorts to GND, the feedback voltage is pulled low, and VSS is discharged. The part soft starts again when it returns to normal conditions.

Pre-Bias Start-Up

For this device, at start-up, if the output feedback voltage is greater than VSS (which means output has pre-bias voltage), neither the HS-FET or LS-FET turn on until VSS exceeds the feedback voltage.

Power Good Indicator

The device has power good (PG) indication. The PG pin is the open drain of a MOSFET. It should be connected to a voltage source through a resistor (e.g. 100kΩ). In the presence of an input voltage, the MOSFET turns on so that the PG pin is pulled to GND before soft start is ready. When the output voltage is within the default ±10% window of rated voltage, PG is pulled high after a delay (typically 30μs). If VOUT moves outside the default ±10% range with a hysteresis, the device pulls PG low to indicate a failure output status. Both the PG threshold and hysteresis can be programmed by the PMBus.

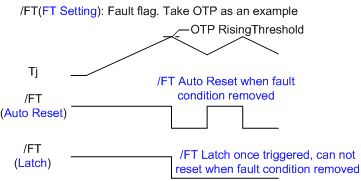

FAULT Indicator

The /FT pin is also an open drain of a MOSFET. It should be connected to a voltage source through a resistor (e.g. 100kΩ). /FT is pulled high in normal operation, and any fault or warning pulls this pin low to indicate a fault status, including input OVP, output OVP, SCP, and thermal shutdown.

Over-Current Protection (OCP)

The device has cycle-by-cycle, over-current limit control. The inductor current is monitored during the HS-FET on state. Once the inductor peak current exceeds the set current limit threshold, the HS-FET immediately turns off. Then the LS-FET turns on to discharge the energy, and the inductor current decreases. The HS-FET does not turn on again until the inductor current falls below the valley current limit. This function helps prevent the inductor current from running away and possibly damaging the components. Both the peak current and valley current threshold can be programmed by the PMBus.

When the peak current limit is triggered, the OCP timer starts immediately. The OCP timer can be set to 32, 64, 128, or 256 cycles by the PMBus. Reaching the current limit in each cycle of this OCP timer triggers SCP operation (hiccup as default), which is detailed in the following section.

Short-Circuit Protection (SCP)

When a short circuit occurs, the device immediately reaches its current limit. Meanwhile, the output voltage quickly drops to the under-voltage threshold (default is 50% of the setting output). The device considers this an output dead short, and directly triggers SCP operation. Three modes can be selected by the PMBus for SCP operation: hiccup as default, switching with non-hiccup, and latch-off.

In default hiccup mode, the device disables its output power stage and resets the soft-start voltage, then initiates a soft start procedure. The off time is determined by the soft-start time and hiccup duty, which can both be set by the PMBus. If the short-circuit condition remains after soft start ends, the device repeats this operation until the short circuit disappears and the output returns to the regulation level. This protection mode greatly reduces the average short-circuit current by periodically restarting the part to alleviate thermal issues and protect the regulator.

Over-Voltage Protection (OVP)

The device monitors the output voltage through the VOUT pin to detect output over-voltage conditions. When the output voltage exceeds the OVP threshold (default is 120% of the setting voltage), OVP mode is triggered. Three modes can be selected by the PMBus for OVP operation: disable as default, discharge, and latch-off.

The device also has optional input OVP. The threshold can be set to 28V or 34V. If VIN exceeds this threshold, the device stops switching. This is a non-latch protection; the device resumes normal operation once the input OVP is removed.

Thermal Shutdown

The device employs thermal protection by internally monitoring the IC temperature. This function prevents the chip from operating at exceedingly high temperatures. If the junction temperature exceeds the threshold (default 175°C), it shuts down the whole chip. This is a non-latch protection, and there is a default 25°C hysteresis. Once the junction temperature drops to about 150°C, the device resumes normal operation by initiating a soft start. Both the OTP threshold and hysteresis can be set by the PMBus.

Floating Driver and Bootstrap Charging

An internal, built-in bootstrap capacitor powers the floating HS-FET driver. When the voltage difference between BST and SW is less than the internal 5V bootstrap regulator, a PMOS pass transistor M1 connected from VIN to BST turns on to charge the bootstrap capacitor. The current path is through D1, M1, C4, L1, and C2 (see Figure 4). If VIN - VSW exceeds 5V, U1 will regulate M1 to maintain a 5V BST voltage across C4. Meanwhile, the external circuit must have enough voltage headroom to accommodate charging. A 10Ω resistor placed between SW and the BST capacitor is strongly recommended to reduce SW spike voltage.

Figure 4: Internal Bootstrap Charging Circuit

As long as VIN is sufficiently higher than VSW, the bootstrap capacitor can be charged. When the HS-FET is on, VIN is about equal to VSW so the bootstrap capacitor cannot charge. The best charging period occurs when the LS-FET is on so that VIN - VSW is at its largest. When there is no current in the inductor, VSW equals VOUT, so the difference between VIN and VOUT can charge the bootstrap capacitor.

In higher duty cycle operation conditions, the internal charging circuit may not have sufficient voltage and time to charge the bootstrap capacitor. In this case, extra external circuitry can be used to ensure the bootstrap voltage is in the normal operation range.

Low-Dropout Operation (BST Refresh)

To improve dropout, the device is designed to operate at close to 100% duty cycle as long as the BST-to-SW voltage is greater than 2.5V. When the voltage from BST to SW drops below 2.5V, the HS-FET turns off using a UVLO circuit, which allows the LS-FET to conduct and refresh the charge on the BST capacitor.

In cases where the input voltage drops, the HS-FET remains on and close to 100% duty cycle to maintain output regulation, until the BST-to-SW voltage falls below 2.5V. Since the supply current sourced from the BST capacitor is low, the HS-FET can remain on for more switching cycles than are required to refresh the capacitor. Therefore, the effective duty cycle of the switching regulator is high.

The effective duty cycle during dropout of the regulator is mainly influenced by the voltage drops across the power MOSFET, inductor resistance, low-side diode, and PCB resistance.

PMBus Control and Default Output Voltage

When the device is enabled (EN = high and VIN > UVLO), the chip starts up to a default 5V output voltage. After that, the PMBus can communicate with the master. Once the PMBus receives valid output voltage set instructions, the output voltage is determined by the PMBus control.

The output voltage setting is set by adjusting the internal reference voltage and output feedback divider ratio. After the device receives a valid data byte of output voltage setting, it searches the corresponding value from the truth table, sends the command of adjusting reference and divider ratio, and finally outputs the right voltage.

CRC Protection

The integrity of OTP is checked after a power-cycle reset. Each time the registers read the OTP contents, the device performs a CRC check. If a CRC error occurs, the registers will try to read two more times. If the error still occurs, the register will read the next available OTP page. If there is no available OTP page, then the CML bit is set in the STATUS_BYTE and STATUS_WORD commands, the appropriate bit is set in the STATUS_MFR_SPECIFIC command, and the ALERTB pin is pulled low.

PMBUS INTERFACE

PMBus Serial Interface Description

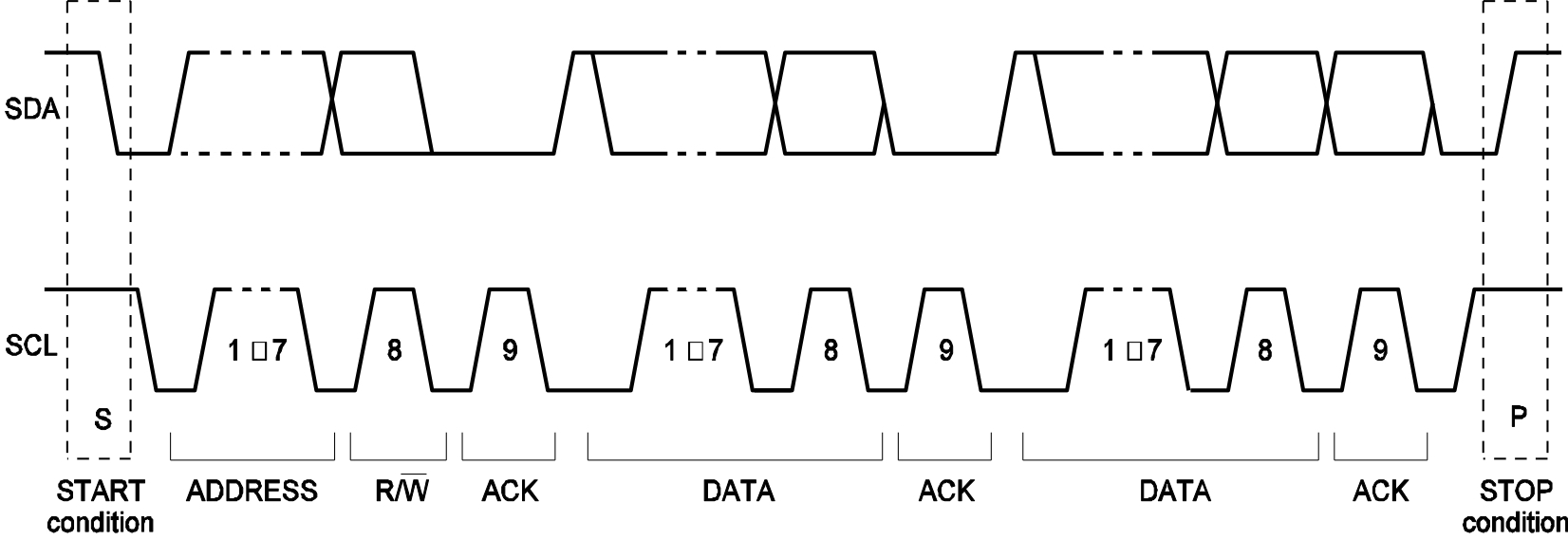

PMBus is a two-wire, bidirectional serial interface, consisting of a data line (SDA) and a clock line (SCL). The lines are externally pulled to a bus voltage when they are idle. Connecting to the line, a master device generates the SCL signal and device address, and arranges the communication sequence. The device interface is a PMBus slave that supports both fast mode (400kHz) and high-speed mode (3.4MHz), adding flexibility to the power supply solution. The output voltage, transition slew rate, and other parameters can be instantaneously controlled via the PMBus interface.

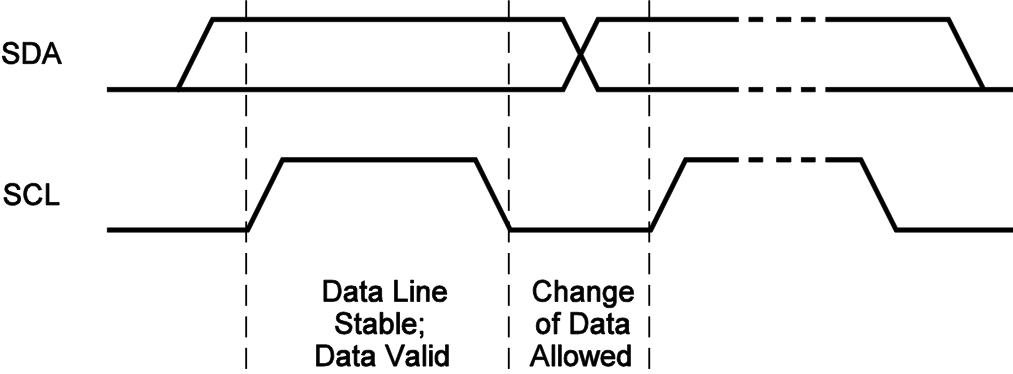

Data Validity

One clock pulse is generated for each data bit transferred. The data on the SDA line must be stable during the high period of the clock. The high or low state of the data line can only change when the clock signal on the SCL line is low (see Figure 5).

Figure 5: Bit Transfer on the PMBus

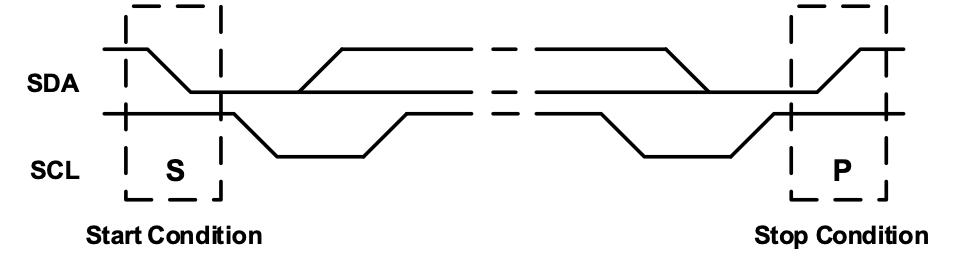

Start and Stop Conditions

The start and stop conditions are signaled by the master device, which signifies the beginning and the end of the PMBus transfer. A start condition (S) is defined as the SDA signal transitioning from high to low while the SCL is high. A stop condition (P) is defined as the SDA signal transitioning from low to high while the SCL is high (see Figure 6).

Figure 6: Start and Stop Conditions

Start and stop conditions are generated always by the master. The bus is considered busy after the start condition. The bus is considered free again after a minimum of 4.7µs after the stop condition. The bus stays busy if a repeated start (Sr) is generated instead of a stop condition. The start and repeated start conditions are functionally identical.

Transfer Data

Every byte put on the SDA line must be 8 bits long. Each byte must be followed by an acknowledge (ACK) bit. The acknowledge-related clock pulse is generated by the master. The transmitter releases the SDA line (high) during the acknowledge clock pulse. The receiver must pull down the SDA line during the acknowledge clock pulse, so that it remains stable low during the high period of the clock pulse.

Figure 7 shows the format that data transfers follow. After the start condition, a slave address is sent. This address is 7 bits long followed by an 8th data direction bit (R/W). A 0 indicates a transmission (write), and a 1 indicates a request for data (read). A data transfer is terminated always by a stop condition, generated by the master. However, if a master still wishes to communicate on the bus, it can generate a repeated start condition and address another slave without first generating a stop condition.

Figure 7: A Complete Data Transfer

PMBus Update Sequence

The device requires a start condition, a valid PMBus address, a register address byte, and a data byte for a single data update. After receipt of each byte, the device acknowledges by pulling the SDA line low during the high period of a single clock pulse. A valid PMBus address selects the device. The device performs an update on the falling edge of the LSB byte.

Device PMBus Chip Address

The ADD pin can be used to program the PMBUS address. The device supports seven addresses for up to seven voltage rails through configuring the resistor value that connecting between the ADD pin and ground. When the master sends the address as an 8-bit value, the 7-bit address should be followed by “0/1” to indicate a write/read operation.

Table 1 shows the resistor values for different PMBus addresses.

Table 1: PMBus Address| Resistor (kΩ) 1% | Address |

|---|---|

| 0 | 21h |

| 12.5 + 25 | 22h |

| 12.5 + 50 | 23h |

| 12.5 + 75 | 24h |

| 12.5 + 100 | 25h |

| 12.5 + 125 | 26h |

| 12.5 + 150 | 27h |

PACKAGE INFORMATION

LGA-45 (10mmx10mmx4.4mm)

NOTICE: The information in this document is subject to change without notice. Please contact MPS for current specifications. Users should warrant and guarantee that third-party Intellectual Property rights are not infringed upon when integrating MPS products into any application. MPS will not assume any legal responsibility for any said applications.

mEZDPD4506 系列产品为可扩展、可编程 DC/DC 电源芯片,峰值输出电流高达 6A。具有两种封装尺寸可选:mEZDPD4506AS 采用表面贴装(LGA 封装),而 mEZDPD4506A 采用 DIP封装(双列直插式封装)。

mEZDPD4506AS具有数字可编程功能,可通过I2C PMBus 控制和编程,可编程的工作参数包括:补偿值、输出电压转换速率、开关频率和省电模式。预先配置的DIP封装模块可以提供快速评估。

想要自定义配置预加载到评估板模块吗?您可以在此创建并保存模块配置,然后 下单购买评估板.

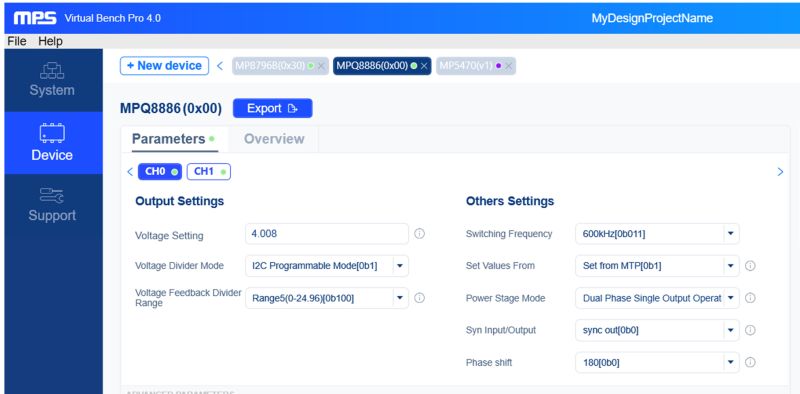

由 MPS 支持的图形用户界面(GUI),用于通过 I2C 接口配置和监控多个 MPS 数字电源解决方案

Virtual Bench Pro 4.0 是一款由 MPS 支持的图形用户界面(GUI),用于通过 I2C 接口配置和监控多个 MPS 数字电源解决方案。此 GUI 是一款直观型工具,可与 MPS 评估套件配合使用,有助于设计评估和测试。

硬件和软件要求:

- USB 转 I2C 通信设备 EVKT-USBI2C-02

- 运行 Windows 10 或更高版本的 PC

- .Net Framework 4.0 或更高版本

- 内存:2GB 可用内存

- CPU:任何现代 CPU

- 磁盘空间:2GB

- 显示器分辨率:1024x768

USB 转 I2C/PMBus 通信接口设备,包含在产品评估套件中,也可单独购买

EVKT-USBI2C-02 包含在产品评估套件中,也可单独购买。该通信接口同时兼容USB 转 I2C 端口和 USB 转 PMBus 端口。它是设计用于 MPS I2C 和 PMBus 产品和虚拟平台及 I2C GUI 工具上。与 MPS 虚拟平台和 I2C GUI一起使用可以简单快速地评估 MPS 的数字产品性能。

EVKT-USBI2C-02 套件包括:

- 1 个 USB 转 I2C 通信设备接口

- 1 根 USB 线

- 1 根 10 芯排线

- 1 根 3 芯排线

- 带有规格书和驱动文件的拇指驱动

¥366.50 + 税

技术论坛

Latest activity 2 years ago

Latest activity 2 years ago

10 回复

10 回复

Latest activity 2 years ago

Latest activity 2 years ago

2 回复

2 回复

Latest activity 2 years ago

Latest activity 2 years ago

2 回复

2 回复

了解更多我们的评估板套件

了解更多我们的评估板套件