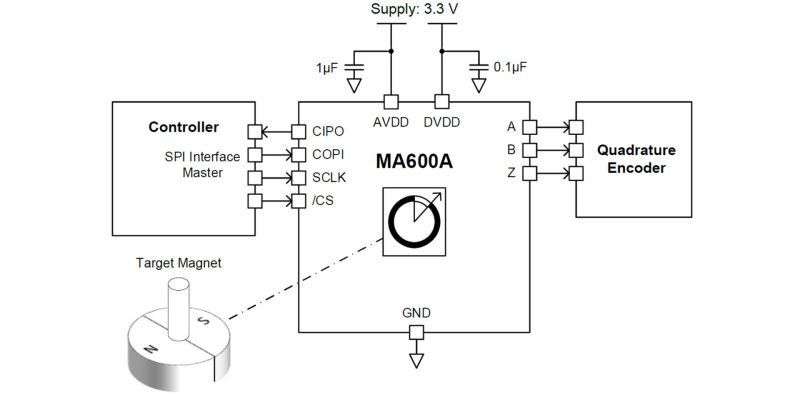

MA600A

High-Accuracy, <0.6° (<0.1°) INL, High-Bandwidth, Configurable, Digital Magnetic Angle Sensor

正在供货产品型号

MA600AGQE-0000-Z MA600AGQE-0000-P MA600AGQE-xxxx-Z MA600AGQE-xxxx-P

P&Z的含义

相关产品

EVKT-LT-KNOB 用于 TBMA-LT 评估板的磁性旋钮

EVKT-LT-KNOB 是一款配有圆柱形磁体的塑料旋钮配件。其设计适用于所有 TBMA-LT 评估板。MACOM 评估套件将 TBMA-LT 评估板连接到 PC,同时 MACOM GUI 显示旋转运动。

磁体经过径向磁化,为 MPS 的 MagAlpha 系列传感器产生正确的输入信号。

EVKT-LT-KNOB 可以与 TBMAxxx-Q-LT-xxx 传感器评估板配合使用,以便在实际条件下快速轻松地测试 MagAlpha 传感器。只需选择所需的 MagAlpha 传感器,然后订购传感器的 EVKT 以及 EVKT-LT-KNOB。

EVKT-MagAlpha-MagDiff 是可以连接到传感器测试板 (TMBA) 和旋钮套件的MagAlpha 通信套件,它需要 Macom 应用软件的配合。

High-Accuracy, High-Bandwidth, Configurable, Digital Magnetic Angle Sensor Evaluation Board

了解更多我们的评估板套件

了解更多我们的评估板套件

直接登录

创建新帐号