差分磁电流传感和位置传感

每月为您发送最具参考价值的行业文章

我们会保障您的隐私

简介

磁传感是一项重要的现代传感技术。它不仅可以提高位置传感和电流传感应用的性能,还能缩小产品尺寸并降低成本。对于位置传感应用,磁传感器提供了一种非接触式的解决方案,这减小了系统尺寸,降低了系统复杂性和维护量,因此是汽车、机器人和工业自动化等应用的理想选择;对于电流传感,磁传感器则通过固有电流隔离确保了安全、精确的测量,它尤其适用于太阳能、变速驱动器、电动汽车充电和电机控制等大功率行业。

随着各行各业对更小、更精确、抗干扰传感器的需求不断增加,差分传感拓扑对于在杂散磁场无可避免的环境中提升传感器精度至关重要。MPS位置传感器产品,如 MA900 和 MAQ79010FS ,就利用差分传感技术实现了关键应用精度与可靠性的提升。

磁传感精度的重要性

汽车、机器人、航空航天和医疗保健等行业对传感解决方案的精度要求越来越高。精确的测量对于实现高安全性和高效率也愈加重要。尤其是在电动汽车 (EV) 等应用中,精确的电流传感对电池管理和电机驱动十分关键,即使是微小的误差也可能导致效率低下甚至系统故障。随着系统复杂性越来越高,对精度的要求也越来越严格,有些应用甚至要求亚度级的角度传感精度和 1%至2% 的电流传感精度。

满足这些标准是极具挑战性的,因为灵敏度提高使传感器更易受到噪声的影响。此时就需要用到差分传感、噪声消除和屏蔽改进等技术。温度的稳定性也很重要,因为传感器读数会随着温度的变化而漂移,尤其是在汽车环境中。此外,随着传感器越来越小以适应紧凑型系统集成,要在不受干扰的情况下保持精度也越来越难。在高性能与成本控制之间取得平衡成为一项关键挑战,尤其是在消费电子产品中。

磁传感中的干扰源

磁传感器很容易受自然和人为外部磁场的干扰。甚至地球磁场都可能带来干扰,使高精度应用中的测量读数失真。此外,电机定子的漏磁通也会干扰附近的传感器,因此需要屏蔽或差分传感。如果传感器附近存在铁磁材料,磁场将会被进一步扭曲,并导致测量精度下降。

磁传感的其他干扰源还包括电感和变压器等载流元件产生的磁场,尤其是在大电流系统中。多相电机中邻相目标磁体间也可能相互干扰,从而产生噪声并使位置传感复杂化。

差分传感拓扑

差分传感通过消除共模干扰来提高磁传感器的精度,这种拓扑结构在外部磁场和噪声严重的环境中非常有效。其设计通过两个或多个传感元件(例如平面霍尔单元或 TMR 元件)测量不同点的磁场,消除外部来源(例如电机或杂散场)的干扰,并聚焦于目标信号。

差分传感的益处包括:

- 降噪以消除对两个传感器产生均等影响的外部场;

- 提升信号保真度,聚焦目标磁信号以实现精确的测量;

- 减少干扰以提高精度,在汽车和工业等应用中提供精确的读数。

差分传感的实现

在电流传感应用中,在载流导体两侧放置两个霍尔效应传感器用于检测磁场,同时消除外部噪声。差分传感可确保精确的电流测量(尤其是在电动汽车电池系统或电机控制等嘈杂环境中),同时提高效率和安全性。

在位置传感应用中,差分拓扑可用于比较不同点的磁场,从而过滤干扰。但需注意,差分传感器需要与目标磁体同轴对齐,因为离轴磁体也被视为干扰场。

除了上述方法外,还可以将多个霍尔元件集成在单个芯片上,以对称方式测量导体周围的磁场,从而提高精度并使传感器在高 EMI 环境中有效工作。对需要高精度和高可靠性的应用而言,霍尔元件是理想的选择。

差分传感适用的应用

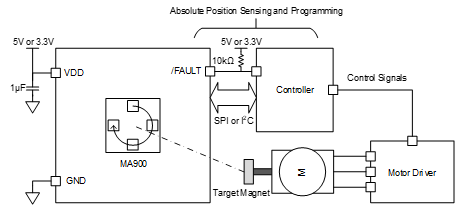

对于需要在嘈杂环境中实现精确位置传感的应用,差分传感拓扑十分必要。例如,在汽车油门控制应用中,采用差分拓扑的磁性位置传感器可以消除发动机组件或外部磁源的干扰,确保精确的油门读数。在电动助力转向系统中,差分传感器可以通过检测转向柱上的磁体位置精确反馈转向角度,并且不受外部噪声的影响。此外,机器人技术也受益于此,即使在强电磁干扰环境中,差分位置传感器也能精确检测关节或运动部件的位置。MA900 和 MAQ79010 等 MPS 传感器即采用该项技术在汽车和工业应用中提供精确可靠的位置检测。图 1所示为MA900 的典型应用。

图1: MA900 的典型应用

在大电流、强噪声环境中,差分电流传感更加必要。例如在电动汽车或可再生能源系统的电池管理系统 (BMS) 中,差分传感器可监测电池电流,实现高效能源管理。在电机控制系统中,这些传感器通过提供精确的电流测量来确保安全高效的运行,即使存在电机噪声也没有影响。同样,在大型机器会产生严重电磁干扰 (EMI)的工业自动化应用中,无论条件多恶劣,MPS 电流传感器都能提供精确的电流读数。

位置传感的权衡与局限

差分位置传感器需要与目标磁体精确同轴对准,才能获得精确的读数。离轴放置可能会导致磁场被误解为干扰,从而限制复杂或多变运动系统的灵活性。因此,谨慎安装差分位置传感器对于在汽车转向和油门控制等应用中提供高精度测量非常关键。

磁场不均匀(梯度)也会导致差分传感精度降低,因为传感器可能会检测到不同的磁场强度。缓解这种状况需要在梯度最小的区域小心放置传感器或进行系统校准,特别是在具有多个磁体或非均匀磁源环境中。

电流传感的权衡与局限

与位置传感不同,差分电流传感只要求更仔细的IC前期设计。无需谨慎对准,差分电流传感器即可精确检测载流导体周围的磁场,并在各种应用中提供多功能性和一致的性能。

差分电流传感需要考量的关键因素包括:确保传感器符合预期的电流范围、管理热稳定性以预防漂移,以及确保为电机驱动等动态应用提供足够的带宽和响应时间。

用例说明

汽车应用

磁传感是电动汽车和高级驾驶辅助系统 (ADAS) 创新的关键。差分传感器是在这类应用中提高精确性和可靠性的重要器件。

- 在电动助力转向 (EPS)系统中,MA900 等传感器能够以亚度精度测量转向角,从而确保顺滑的控制。

- 在电池管理系统 (BMS) 中,电流传感器能够以高精度监控充电和放电过程,即使环境嘈杂也不受干扰。

- 在牵引电机控制系统中,差分电流传感器可提供实时电流测量,从而优化电动汽车的电机效率和安全性。

汽车应用中的差分传感器能够增强控制能力并延长电池寿命。它不仅能在嘈杂的环境中可靠地运行,还能在低功耗模式下高效率运行,从而延长电动汽车的行驶里程。

消费类(低功耗)应用

消费电子产品对紧凑型、低功耗的传感器需求也日益增长,差分传感器是满足这些需求的绝佳解决方案。

- 在游戏控制器和操纵杆应用中,MA900无需移动部件即可提供精确、可靠的反馈。

- 在智能手表和健身追踪器等可穿戴设备中,差分传感器能够实现超小尺寸、低功耗和精确的表盘移动检测。

- 在家庭自动化领域,差分传感器可在智能锁和安全摄像头等应用中实现低功耗、精确的位置感应。

在低功耗的消费类应用中,差分传感器作为一种节能传感器不仅可延长器件电池寿命,紧凑的外形还可在空间受限设备中实现更小的设计,而且由于没有活动部件还具有更长的使用寿命。

医疗应用

差分传感器在要求很高的医疗环境中也可提供高精度和高可靠性。

- 即使在具有强磁场的磁共振成像(MRI)仪中,差分传感器也能够提供精确的电流传感。

- 在假肢和可穿戴设备中,差分传感器能够以高精度控制并监测运动和康复锻炼。

- 在手术机器人应用中,多轴紧密靠近的差分传感器可提供亚毫米级的定位能力。

新兴技术

磁传感技术正在快速发展,以满足汽车、医疗保健和消费电子等领域对精度、效率和适应性日益增长的需求。下面列出了磁传感技术的一些重大进步:

- 业界正在开发可以更精确地检测更小磁场变化的传感器,这种新型传感器特别适用于自动驾驶应用。

- 多轴传感传感器能够检测多个轴(X、Y 和 Z)的磁场,从而实现更复杂的应用,例如机器人和增强现实 (AR) 中的3D定位。

- 具有更高灵敏度和更低固有噪声的隧道磁阻 (TMR) 等新型磁传感器技术可以将精度提升到新的高度

行业趋势

对精确磁传感的需求是应用复杂性不断增加的直接结果。例如在汽车行业,自动驾驶汽车和 ADAS 依靠精确的磁传感器来实现车道保持并避免碰撞;在医疗保健领域,MRI仪器和机器人手术系统需要高精度以确保安全性和治疗效果;工业自动化领域的机械臂和传送系统也需要精确感应,从而提高效率并减少误差。

微型化和成本的降低推动了磁传感技术的进一步创新。尺寸更小的传感器能够被集成到紧凑型系统(例如可穿戴设备和无人机)中,同时又不牺牲精度。对于医疗可穿戴设备和工业物联网 (IoT) 系统等设备,节能传感器在延长电池寿命方面起到了关键的作用,并进一步推动了低功耗设计方面的创新。

结语

对于外部磁场干扰会影响精度和性能的汽车、工业自动化和医疗设备等行业来说,磁传感技术非常重要。MPS 位置传感器(例如 MA900 和 MAQ79010FS)和电流传感器中应用了差分传感拓扑结构,可消除共模噪声并确保器件可靠、高精度的运行。

未来,降噪、小型化和材料科学方面的进步将进一步推动磁传感技术的创新,从而满足对传感器精度更高、功耗更低和尺寸更小的需求。从电动汽车到医疗可穿戴设备,磁传感器在这些应用中将变得越来越重要。

即刻探索 MPS 的 电流传感器 和 位置传感器 ,为您的设计找到最恰当的解决方案。

_______________________

您感兴趣吗? 点击订阅,我们将每月为您发送最具价值的资讯!

技术论坛

Latest activity 4 months ago

Latest activity 4 months ago

12 回复

12 回复

Latest activity a year ago

Latest activity a year ago

1 评论

1 评论

Latest activity 2 months ago

Latest activity 2 months ago

22 回复

22 回复

直接登录

创建新帐号