What Are Gate Drivers? A Brief Introduction

Gate drivers are essential parts of the power electronics ecosystem that play a crucial role in managing power components like transistors and thyristors. Anyone participating in the design and implementation of power electronic systems has to have a thorough understanding of the function and operation of gate drivers.

Function and Purpose

Gate drivers are electronic circuits that control how well power switches work. These switches include IGBTs, MOSFETs, and other semiconductor devices used in power electronics. Turning these power switches on and off is a gate driver's main job; it allows you to regulate the system's power supply.

Key Characteristics

Voltage and Current Control: To turn on or off a power semiconductor device, gate drivers supply the voltage and current that are required. They guarantee that sufficient force (voltage or current) is applied to the gate in order to perform effective switching.

Speed of Operation: The ability of gate drivers to quickly turn power devices on and off is one of their most important features. Power electronic systems must transition quickly in order to reduce power losses and increase efficiency.

Protection Features: To protect the power devices and the system as a whole, modern gate drivers frequently include a number of protection measures. These consist of thermal shutdown, short-circuit protection, over-current protection, and under-voltage lockout.

Driving High-Power Devices: To switch power devices efficiently in high-power applications, significant gate drive currents are needed. Because gate drivers are made to withstand such high currents, the power devices will operate reliably.

Applications

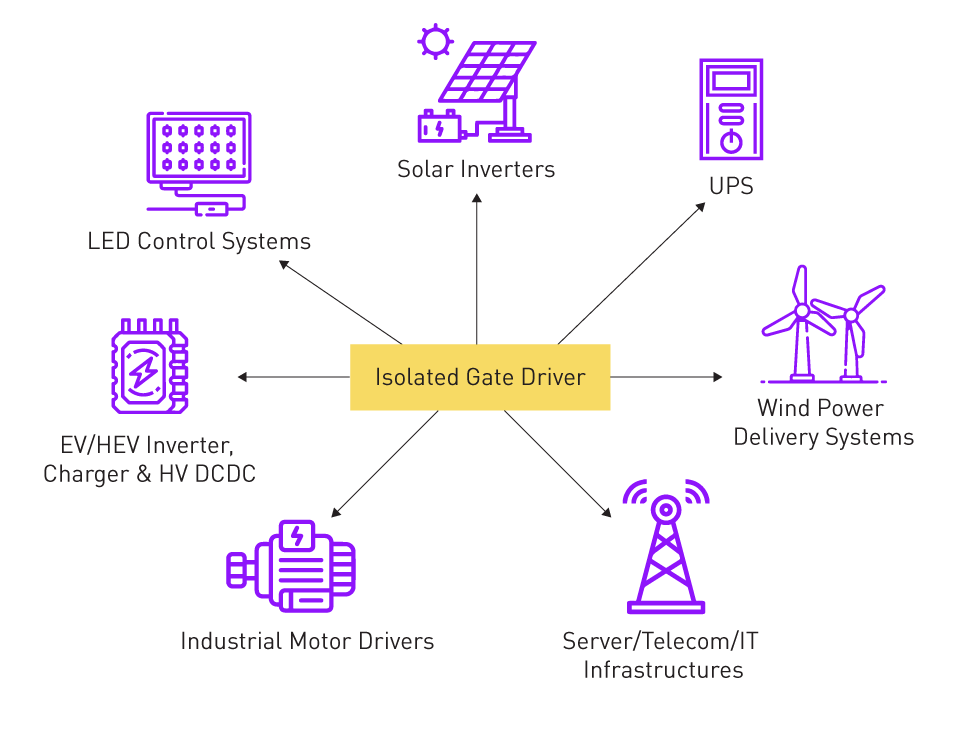

Applications for gate drivers are numerous and include sophisticated motor drives, renewable energy systems, and basic DC/DC converters. They are a crucial component of many applications that use power electronic devices, such as electric vehicles, LED lighting systems, power supplies, and inverters.

Role of Isolation in Gate Drivers

A crucial component of power electronic systems is isolation in gate drivers, which is essential to maintaining the systems' operational integrity and safety. Gate drivers, who frequently have to work in electrically noisy environments or at various potential levels, are responsible for controlling high-power semiconductor devices. Isolation becomes essential in this situation.

Figure 1: Common Applications of Isolated Gate Drivers

Importance of Isolation

Electrical Safety: For electrical safety, gate drivers must be isolated. It shields the operator and the delicate control electronics components by keeping high voltages from the power switch from getting to the control circuitry or the user interface.

Noise Immunity: Electrical noise originating from power electronic equipment is frequently considerable. Isolating the gate driver from transient voltages and electromagnetic interference keeps the gate driver signals safe while also keeping the control circuitry safe from noise of this kind.

Level Shifting: The control circuitry often runs at a different voltage level than the power device in numerous applications. Level shifting is made possible by isolation, which enables the control circuit to run at a secure, low-voltage level while powering high-voltage devices.

Preventing Ground Loops: Ground potential discrepancies can result in ground loops in systems with several power supplies and control circuits. Isolated gate drivers stop these loops, which could cause undesirable currents and obstruct the system's normal operation.

Implementation of Isolation in Gate Drivers

Optocouplers and Digital Isolators: Digital isolators and optocouplers are frequently utilized in gate drivers to provide isolation. When transferring signals over an isolation barrier, optocouplers use light, whereas digital isolators use capacitive or magnetic coupling.

Integrated Isolated Gate Drivers: Some gate drivers have built-in isolation, which improves dependability and simplifies design. These integrated solutions frequently offer high-speed operation and cutting-edge features like error detection and protection systems.

Transformer-Based Isolation: Transformers are employed in gate drivers for both signal isolation and power transfer to the power device's gate in some high-power applications.

Challenges and Considerations

Maintaining Signal Integrity: It is essential to make sure that the gate drive signal crosses the isolation barrier precisely. Any distortion or delay brought on by the isolation technique may have an impact on the power switch's functionality.

Thermal Management: Especially in high-power applications, isolated gate drivers can produce a lot of heat, so they need to be cooled down properly.

Size and Integration: As a result of the downsizing trend, isolated gate drivers' sizes must be taken into account during the design process. Smaller, more integrated isolation solutions are now possible because of advancements in semiconductor technology.

A Quick Overview of Power Modules

In the field of power electronics, power modules are essential elements that are responsible for the effective conversion and control of electrical power in a variety of applications. These modules are basically integrated assemblies that usually consist of multiple power components packaged together.

Essential Aspects

Functional Integration: Transistors (such as MOSFETs or IGBTs), diodes, and occasionally gate drivers are integrated into a single power module to provide essential power electronic components. Compact designs are made easier by this integration, which also improves system reliability overall.

Types of Power Modules: Power modules might differ in terms of the components they integrate and the functionality they offer based on their intended use. Inverter modules, motor control modules, and converter modules (AC/DC or DC/DC) are common types.

Application in Power Conversion: Power modules are frequently employed in settings where effective control and power conversion are necessary. This covers electric car powertrains, motor drives, power supplies for electronics, and inverters for renewable energy systems.

Thermal Management: Power modules handle large amounts of electrical energy, therefore, thermal management needs to be done well. Heat sinks and sophisticated packaging methods are just two examples of the materials and construction used in the creation of these modules to aid in heat dissipation.

Electrical Efficiency: In applications that are energy-sensitive, power modules' efficiency is a crucial factor. High efficiency increases the system's overall performance and lifespan by minimizing energy losses and reducing heat generation.

Customization for Specific Needs: Power modules are frequently made to meet particular needs. This modification takes into account factors like switching frequency, voltage and current ratings, and thermal performance specifications.

Benefits of Using Power Modules

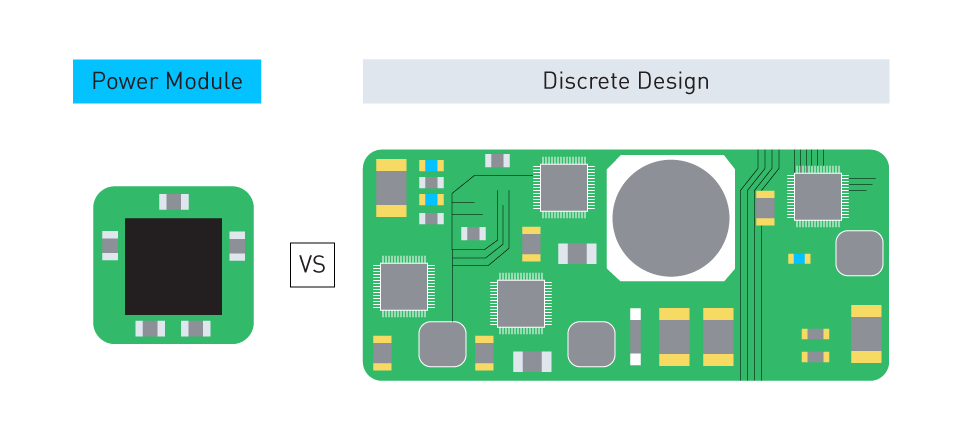

Simplified System Design: Power modules make it easier to design and assemble power electronic systems by combining several components into a single box.

Figure 2: Integrated Power Module vs. Discrete Design

Enhanced Reliability: By reducing the number of connections, which may serve as possible points of failure, the integration of components in power modules improves system reliability.

Compact Size: The ability to construct more compactly is made possible by power modules, which is a big benefit in situations where space is at a premium.

Necessity of Isolation in Power Modules

Power module isolation is a crucial component of design that addresses power electronic systems' functional integrity and safety. Power modules are utilized in many critical applications and frequently operate at high voltages, so implementing isolation inside these modules is essential to guaranteeing the safe and dependable operation of these systems as well as complying with regulatory requirements.

Safety and Protection

User Safety: Isolation prevents electric shocks in situations where power modules connect with equipment that is accessible to users or when they are operated in close proximity to operators. This is especially crucial for medical devices, industrial gear, and consumer electronics.

Equipment Safety: isolation shields power modules' delicate control electronics from high-voltage transients. This safeguard is essential for avoiding electronic damage, which can result in system malfunctions and expensive downtime.

Functional Integrity

Preventing Electrical Noise Interference: Electrical noise from power modules can be rather high. By preventing this noise from impacting delicate control circuits, isolation inside these modules contributes to reliable and accurate functioning.

Mitigating Ground Loop Issues: In systems with several power modules, variations in ground potentials can result in ground loops, which provide unintended current channels that might impair system performance. These ground loops are reduced in part via isolation inside power modules.

Regulatory Compliance

Meeting International Standards: Power modules have to abide by a number of international safety standards, many of which require a certain level of isolation. The safety of the power modules for usage in the intended applications is guaranteed by these standards.

Design and Implementation Considerations

Choice of Isolation Technology: Depending on the voltage levels, power needs, and environmental factors of the application, a power module's power isolation technology (such as capacitive, magnetic, or optical) should be chosen.

Integration Challenges: Including isolation in power modules can be difficult from a design standpoint, especially when it comes to keeping things small and controlling heat. In order to maintain the effectiveness of isolation, designers must strike a balance between these aspects.

Cost and Efficiency: The implementation of isolation may have an impact on the cost and efficiency of power modules. It's critical to create isolation solutions that are economical without sacrificing the module's overall performance.

直接登录

创建新帐号