Safety

Protection of Users and Equipment against High Voltages

Protecting humans and equipment from excessive voltages is one of the main goals of adopting isolation in electrical circuits. By its very nature, high voltage presents a serious risk of electric shock or damage to equipment. It is critical to protect users from electrical risks in situations where there is frequent user interaction with electronic devices, such as in consumer electronics, medical equipment, or industrial control systems.

Parts of the circuit that users may come into contact with are shielded from high voltage by an electrical and physical barrier that is provided by isolation. This barrier is intended to resist particular voltage levels, so even in the event of a voltage spike or surge, the dangerous voltage will not cross the isolation barrier. It is not just a simple separation. Equivalent importance is given to equipment protection. Exposure to high voltages can harm the delicate parts of electrical devices. These parts are protected against these kinds of voltages by being isolated. These voltages can come from power supply circuits or other parts of the circuit working normally, or they can come from outside sources like lightning strikes or power line failures.

Compliance with Isolation Standards

Another crucial component of the requirement for isolation in electronic systems is adherence to isolation standards. There are a number of national and international standards that govern the requirements for electrical isolation to ensure dependability and safety. Organizations like Underwriters Laboratories (UL), the Institute of Electrical and Electronics Engineers (IEEE), and the International Electrotechnical Commission (IEC) set these standards.

These standards outline requirements for isolation voltage levels, insulation resistance, and isolation barrier testing procedures, among other things. They make sure that the established isolation offers sufficient defense against electrical breakdown and arcing, in addition to physically separating high-voltage and low-voltage components.

One typical safety standard for industrial, educational, and laboratory equipment is the IEC 61010 standard. It establishes insulation standards for solid insulation, dielectric strength, and clearance distances. Similar to this, UL safety regulations—particularly in consumer electronics—determine the design specifications for isolation.

Maintaining end-user safety and product dependability are the two main goals of complying with these standards, in addition to following the law. Electronic equipment designers and manufacturers are required to make sure that their products adhere to these standards, which frequently call for stringent certification and testing procedures.

Isolation is necessary in electronic circuits for two reasons: first, to comply with international safety requirements; and second, to safeguard users and equipment from the risks associated with high voltages. These specifications are essential to the construction and functionality of many different kinds of electronic equipment, supporting their dependability and safety.

Signal Integrity

Prevention of Ground Loops

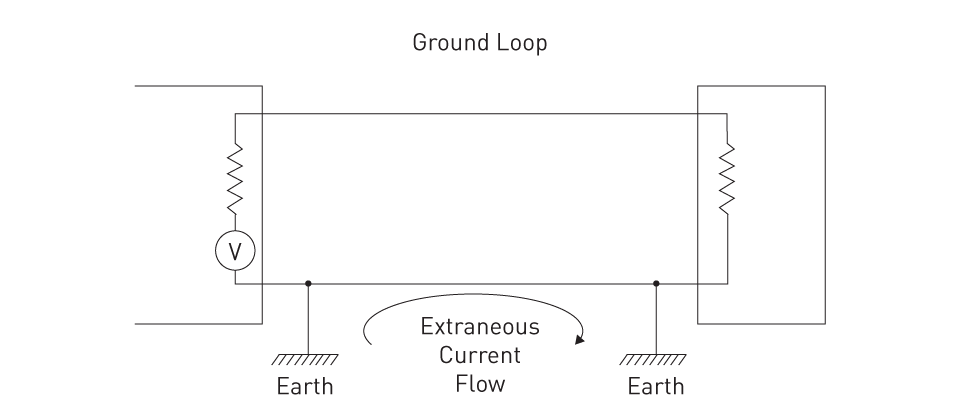

In electrical systems, ground loops are a common problem, especially in large installations with lots of connected components. When there are several paths to ground in an electrical system, a ground loop happens. This causes a cyclical flow of current that can cause interference and undesired noise in the signal lines. This phenomenon can cause buzzes, hums, or distortions in the visual field in audio and video systems, which makes it particularly problematic.

Figure 1: Ground Loop

A key strategy for avoiding ground loops is isolation. Isolation works by electrically dividing circuit segments, ensuring that every component has a single, dedicated path to ground and removing the possibility of circular currents. For instance, isolators are used in audio systems to break possible ground loops between various stages or devices (such as an amplifier and mixer), thereby maintaining the audio signal's quality.

Careful consideration of the circuit design, including the location of isolators and the management of ground connections, is required when implementing isolation to prevent ground loops. The intention is to avoid developing multiple, conflicting pathways by making sure that every component of the system is correctly referred to a single ground point.

Signal Isolation and Conditioning

Signal conditioning and isolation are essential for preserving a signal's integrity as it passes through various electrical system components. In this case, isolation has two main purposes:

Electrical Isolation: This technique keeps high-voltage transients or surges from harming a system's other components. Sensitive measuring or diagnostic equipment must be shielded from electrical noise and disturbances in the surrounding environment in industrial and medical applications.

Signal Conditioning: This is the process of altering a signal to get it ready for the next processing step. This can involve changing the signal's form (such as from analog to digital), filtering, or amplification. Often included in the signal conditioning process, isolation makes sure that the signal is safeguarded from electrical interference while it is being transformed to meet processing requirements.

In systems where data precision and accuracy are critical, signal conditioning and isolation are especially important. For instance, conditioning and isolating signals in data gathering systems used for scientific measurements guarantee that the data is accurate, dependable, and free from outside influences that could distort results.

Noise Reduction

Importance of Noise Isolation

In electronic circuits, noise isolation plays a critical role in guaranteeing the correctness and dependability of system performance. Electrical noise, which can originate from a wide range of internal and external sources like internal circuit components, electromagnetic interference (EMI), and radio frequency interference (RFI), can seriously hinder electronic systems. This is especially true for applications requiring precision, such as data converters, communication systems, and instrumentation.

In order to effectively isolate noise, an electrical barrier must be built to stop noise from one area of a circuit from entering and impacting another. Physical separation, the use of isolating parts like optocouplers or digital isolators, and the application of shielding techniques are some of the ways this barrier can be created.

The following are some of the reasons noise isolation is important:

Enhance Signal Quality: By maintaining the integrity of the signal and separating sensitive components from noise sources, the system's output will be more accurate and reliable.

Prevent System Malfunctions: Excessive noise levels can cause a variety of system problems, such as inaccurate measurements, unexpected behavior, and, in the worst situations, total system failure.

Facilitate Miniaturization: Noise contamination is increased when high-speed digital circuits are placed close to analog circuitry in electronic systems that are getting smaller. In these tinier settings, efficient noise isolation techniques are crucial.

Impact of Noise on System Performance

Noise can have a significant and diverse impact on system performance, influencing various electrical system features in multiple ways. Data Integrity: Errors in data processing and transmission caused by noise can result in corrupted data in digital systems. This is particularly important for applications like data transfer, where the correctness of the information being transmitted is crucial.

Measurement Accuracy: Noise in precision measurement systems, like those found in scientific and medical equipment, can cause readings and measurements to be inaccurate, which could jeopardize the accuracy of the findings.

Operational Stability: Noise can throw systems into disarray, especially in control or feedback loops where it can result in erratic or oscillating behavior.

Audio and Video Quality: Noise can severely impair audio and visual outputs in multimedia applications, causing disruptions such as buzzing, humming, or visual artifacts.

Reduced Lifespan: Electronic components may become more stressed after extended exposure to loud noises, which could shorten their lifespan and affect their dependability.

To sum up, noise isolation is an essential component of electronic system design that is necessary to preserve overall system performance and dependability, ensure accurate data transfer, and maintain signal integrity. Engineers and designers will continue to place a high priority on good noise isolation techniques as electronics develop and become more integrated and complicated.

Functional Separation

Segregating Circuit Elements to Maintain Independent Operations

In electronic systems, functional separation by isolation is a crucial design technique used to divide off different circuit elements so they can function separately and unhindered. In complicated electronic systems where numerous functions coexist within a single device, this element of isolation is especially crucial.

Making sure that the functioning of one component of a system does not negatively impact or obstruct the performance of another is the main goal of functional separation. By electrically separating various circuit segments, it is possible to prevent interactions that could endanger the system's functionality.

Key aspects and benefits of functional separation include:

Modularity and Flexibility: Circuit design can be approached modularly thanks to isolation. Before being incorporated into the overall system, individual modules or parts can be created, tested, and optimized. Additionally, because of its modularity, the design is more flexible, making updates and alterations simpler.

Reduced Interference: Functional separation is crucial in systems that have both analog and digital components and high-power and low-power circuits coexisting, such as mixed-signal systems. Isolation from high-power components protects sensitive low-power circuits from noise and disturbances.

Enhanced Reliability: Isolation contributes to an overall increase in system dependability by separating circuit parts. Isolation can stop a defect or failure in one system component from spreading to other components, isolating the problem and making debugging easier.

Safety Compliance: Functional separation is not only a design decision but also a necessity in some applications, particularly in industrial and medical settings. By isolating various functional elements, like power and control circuits, isolation helps prevent potentially dangerous interactions.

Targeted Performance Optimization: Through isolation, engineers can individually enhance the performance of certain circuit segments. A neighboring power management unit, for example, could be tuned for stability and low noise, while a high-speed data processing unit would be optimized for speed and efficiency.

Prevention of Feedback Loops: Occasionally, feedback loops in signal processing and control circuits can cause oscillations and instability. This kind of undesirable feedback between several stages of a circuit can be avoided with the use of isolation.

In conclusion, a fundamental design principle in electrical engineering is functional separation through isolation, which permits the independent operation of various circuit elements. Achieving certain performance requirements, improving system reliability, guaranteeing safety, and offering the flexibility required in contemporary electronic design all depend on this separation. Sophisticated electronic system development relies heavily on the capacity to isolate various processes inside the system, which is the foundation for many technological advancements in the field.

直接登录

创建新帐号