Industrial Automation

In industrial automation, digital isolators play a crucial role by providing notable performance benefits and bolstering the dependability of automated systems. The distinctive qualities of these materials are a perfect fit for the rigorous demands of industrial settings.

Performance Advantage in Industrial Automation

Robustness in Harsh Environments: Industrial settings frequently encounter challenging conditions, including high temperatures, electrical noise, and mechanical vibrations. With their solid-state construction, digital isolators are known for their robustness, making them ideal for challenging environments.

High-Speed Data Transfer: For efficient operation, numerous industrial automation systems rely on the rapid and precise transfer of data to facilitate control and monitoring. Digital isolators are essential for seamless high-speed data communication, guaranteeing accurate and prompt command execution in automation processes.

Electrical Noise Immunity: Dealing with electrical noise is a major hurdle in the field of industrial automation. This noise can come from different sources, such as powerful motors, switching devices, and power lines. Digital isolators offer exceptional noise immunity, guaranteeing the integrity of control signals and data, which is vital for preserving system accuracy and consistency.

Compatibility with Modern Control Systems: With the rise of digitization and networking in industrial automation, digital isolators seamlessly integrate into modern industrial communication protocols and networks. This enables smoother integration into complex automation systems.

Improving Reliability in Industrial Settings

System Uptime and Fault Tolerance: In industrial applications, minimizing downtime is crucial due to the potential financial impact. Digital isolators play a crucial role in ensuring system uptime by offering dependable isolation and effectively safeguarding against electrical surges and transients to prevent failures. Reliability plays a vital role in ensuring the smooth operation of industrial processes.

Safety and Protection: Digital isolators play a crucial role in maintaining the safety of equipment and personnel. Through the implementation of efficient isolation measures, they ensure that electrical faults do not spread throughout the system, thereby safeguarding equipment and protecting workers from potential safety hazards.

Longevity and Maintenance: Digital isolators have a clear advantage over electromechanical isolating components in terms of longevity and maintenance. Thanks to their solid-state nature, digital isolators have longer operating lifespans and require less maintenance. This durability is advantageous in minimizing the overall expenses for maintenance and replacement in industrial environments.

Predictive Maintenance: With the inclusion of digital isolators in sensor networks and monitoring systems, more advanced predictive maintenance strategies can be implemented. By guaranteeing dependable data transmission from sensors, digital isolators enable the early identification of possible equipment malfunctions, enabling proactive maintenance measures.

Medical Electronics

Within the realm of medical electronics, the utilization of digital isolators holds immense importance due to the strict safety standards and the necessity for top-notch performance, precision, and dependability in medical devices.

Ensuring Patient Safety

Critical Role in Patient Protection: In the field of medical electronics, ensuring the safety of patients is absolutely essential. Effective electrical isolation is essential for ensuring the safety of patients, especially with devices that directly interact with them, such as ECG monitors and infusion pumps. Digital isolators play a vital role in providing this protection against electric shock.

Compliance with Medical Safety Standards: Medical devices must meet strict international safety standards, such as IEC 60601, which outline rigorous isolation requirements. Digital isolators play a crucial role in ensuring that medical devices meet the required standards, as they offer dependable and robust electrical isolation.

Minimizing Leakage Current: Ensuring minimal leakage current is crucial for maintaining safety standards in medical electronics. With their exceptional isolation capabilities, digital isolators play a crucial role in minimizing leakage currents, which ultimately improves patient safety.

Improved Performance and Reliability

Reliability in Critical Applications: Medical devices frequently operate in life-critical situations, where ensuring reliability is absolutely essential. Digital isolators provide a high level of reliability due to their solid-state construction, unlike mechanical relays that can be prone to wear and tear.

Enhanced Signal Integrity: In medical diagnostics and monitoring, maintaining the accuracy and integrity of the signal is of utmost importance. Digital isolators play a crucial role in maintaining the accuracy of digital signals, which is especially vital for devices such as digital imaging systems and patient monitoring equipment. They ensure that readings and diagnostics remain precise, preserving the integrity of the data.

Noise Immunity: In medical environments, there are numerous sources of electrical noise that can disrupt the delicate electronics found in medical devices. Digital isolators offer excellent protection against electromagnetic interference (EMI), guaranteeing the uncompromised performance of medical devices.

Facilitation of Advanced Features: The integration capabilities of digital isolators are a great fit for the growing demand for smarter, more connected medical devices. They enable the integration of cutting-edge functionalities such as wireless connectivity and remote monitoring, all while ensuring the highest levels of safety and performance.

Communication Systems

Within the realm of communication systems, digital isolators have become an essential element, greatly improving the overall performance and efficiency of the system. Their role in ensuring signal integrity, seamless integration, and optimal power efficiency is driving their increasing use in a wide range of communication applications.

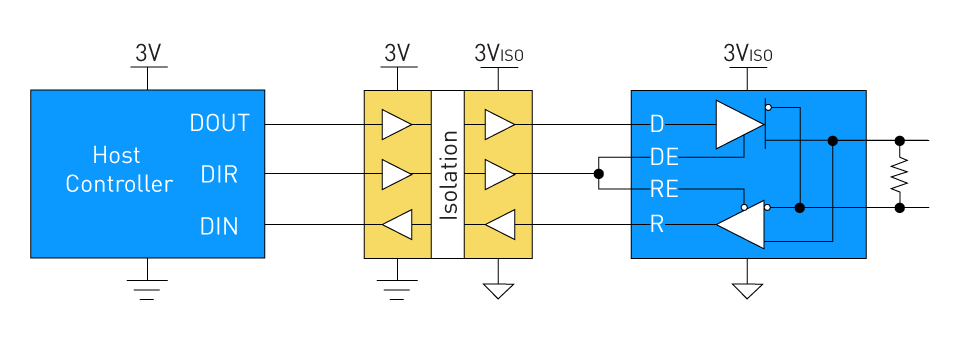

Figure 1: Isolated RS-485 Interface

Higher Signal Integrity via Reduced Noise and Interference

Mitigating Signal Distortion: Digital isolators are highly effective in addressing signal distortion that arises from noise and interference commonly found in communication systems. Through the careful separation of the signal path from any potential sources of interference, digital isolators effectively safeguard the integrity of transmitted data.

Immunity to Electromagnetic Interference (EMI): Communication systems can experience significant signal degradation due to electromagnetic interference (EMI). Digital isolators provide exceptional resistance to electromagnetic interference, guaranteeing the integrity of signals and ensuring reliable transmission of data.

Preserving Data Integrity: In the realm of digital communication, it is crucial to maintain the integrity of data packets. Digital isolators play a crucial role in preserving data integrity, especially in environments with significant electrical interference. This, in turn, improves the overall reliability of communication.

Ease of Integration

Compatibility with Modern Digital Systems: Digital isolators effortlessly blend with the latest digital communication protocols and systems, making them a perfect fit for various communication technologies.

Flexibility in Design: The compact and versatile nature of digital isolators offers a wide range of design options, making them suitable for use in different form factors and communication systems. They can be used in anything from simple point-to-point interfaces to complex networked solutions.

Simplification of Circuit Design: Incorporating digital isolation into communication systems streamlines circuit design by eliminating the need for extra components and intricate layout considerations typically required by analog isolation methods.

Lower Power Consumption

Energy Efficiency: When compared to more conventional techniques of isolation, digital isolators are typically more inefficient in terms of energy use. For systems that emphasize lowering power consumption or for communication devices that run on batteries, this efficiency is especially useful.

Reduced Heat Generation: As a result of their lower power consumption, digital isolators produce less heat because they generate less heat. This helps to mitigate thermal management difficulties in communication devices and contributes to the longevity of the system.

Suitability for Remote and Wireless Applications: Digital isolators' high power efficiency makes them perfect for usage in wireless devices and remote communication systems, where efficiency is crucial and power availability is constrained.

Renewable Energy Systems

Digital isolators are essential for improving the robustness, safety, and dependability of systems like wind energy and solar inverters in the quickly developing renewable energy industry. They make a substantial contribution to resolving the particular issues raised by these green energy sources.

Ensuring Safety, Reliability, and Robustness in Solar Inverters and Wind Energy Systems

Safety in High-Voltage Environments: Solar inverters, in particular, are frequently used in renewable energy systems that run at high voltages. Between the lower-voltage control circuitry and the high-voltage side (such as solar panels), digital isolators offer crucial electrical isolation. In order to safeguard people and equipment from potential electrical risks, this isolation is essential.

Reliability in Varied Environmental Conditions: Renewable energy systems are subjected to a variety of environmental factors, including temperature changes, humidity, and mechanical strains, particularly in wind energy applications. Solid-state digital isolators, noted for their dependability and low susceptibility to environmental influences, provide consistent performance under such varying situations.

Robustness Against Transients and Surges: Transients and surges, which are frequently caused by lightning strikes or grid instability, are a common occurrence in solar and wind energy systems. By efficiently managing these fleeting occurrences, digital isolators can protect the delicate electronic parts of renewable energy systems.

Performance in Grid-Connected Systems: It is crucial to preserve the quality of power delivered into the grid for grid-connected solar and wind systems. By helping to precisely regulate and monitor power conversion procedures, digital isolators help to guarantee that the energy sent into the grid satisfies the necessary requirements.

Longevity and Lower Maintenance: Since digital isolators don't have moving parts or other wear-and-tear-prone components, they have a longer operational life and require less maintenance, which is especially advantageous considering how many renewable energy installations are located in remote or difficult-to-reach locations.

Efficient Energy Conversion: By guaranteeing precise signal transfer between the control unit and power-switching elements, digital isolators in solar inverters contribute to the effective conversion of DC to AC power. In order to maximize the energy generation from solar panels, this efficiency is essential.

Scalability for Large Systems: Scalable control and monitoring systems are necessary for renewable energy installations, especially solar farms and massive wind turbines. Digital isolators, which enable the integration of numerous panels or turbines into a coherent and controllable system, make this scalability possible.

直接登录

创建新帐号