Balancing Power and Performance

One of the major challenges in the realm of digital isolators with integrated power design is attaining a balance between system performance and power consumption. Achieving this balance is crucial for ensuring the efficiency and efficacy of the system across diverse applications.

Challenges in Achieving High Performance with Lower Power

Tradeoff Between Efficiency and Speed: The inherent trade-off between high-speed performance and power efficiency is one of the main challenges. In power-sensitive applications, the higher power consumption required for high-speed operation can pose a significant concern.

Thermal Management Issues: The increase in power consumption correlates with the heat rise generated by the components. Effectively managing this heat without compromising performance poses a challenge, particularly in compact designs.

Voltage and Current Limitations: Incorporating low power consumption design can limit the voltage and current handling capabilities of the system, potentially impacting performance in high-power applications.

Component Selection Constraints: It can be challenging to select components that meet both low power and high-performance criteria. Components with high efficiency might not always meet the performance requirements, or they could be cost-prohibitive.

Strategies to Overcome Design Limitations

Advanced Semiconductor Technologies: Advanced semiconductor materials such as Silicon Carbide (Sic) or Gallium Nitride (GaN) are utilized to attain greater efficiency and performance. Better power handling and faster switching capabilities are offered by these materials.

Optimized Circuit Design: Balancing power consumption with performance can be achieved through careful circuit design, which includes utilizing efficient switching techniques and implementing power-saving modes. Pulse-width modulation (PWM) and dynamic power scaling techniques are effective strategies.

Thermal Management Solutions: To mitigate the thermal issues associated with high-performance operation, it is essential to implement effective thermal management techniques, such as heat sinks, thermal vias, and proper layout for heat dissipation.

Power-Performance Tradeoff Analysis: The design process can be guided by conducting a thorough analysis of the power-performance trade-off for the specific application. Evaluating the minimum performance requirements against the power constraints to find an optimal balance is involved in this process.

Use of Energy Harvesting: Energy harvesting from environmental sources, such as vibrations, light, or thermal differences, can be utilized in certain applications to supplement the power supply and aid in balancing the power budget.

Ensuring Reliability and Longevity

In electronic system design, the longevity and reliability of digital isolators are paramount, and both are attained by a robust design approach and careful consideration of long-term reliability factors.

Importance of Robust Design

Critical Role in System Stability: Ensuring the stability and consistent performance of the entire system mandates robust design in digital isolators. Creating designs that can withstand various stress factors such as thermal extremes, voltage fluctuations, and physical stresses is involved.

Fault Tolerance: Incorporating elements of fault tolerance, a robust design ensures that the system can continue to operate correctly even in the presence of certain faults. Features like redundancy, self-diagnosis, and protective circuitry are involved in this.

Adaptability to Environmental Conditions: It is essential for the design to consider the environmental conditions under which the isolator will operate. Considerations for humidity, temperature ranges, vibration, and other external factors that could impact performance over time are encompassed in this.

Quality of Components: It is crucial to select high-quality components that meet or exceed the required specifications. Not only does this encompass the isolator itself, but it also includes associated components like capacitors, inductors, and PCB materials.

Long-Term Reliability Considerations

Aging and Wear-out Mechanisms: It's essential to understand and account for the aging and wear-out mechanisms of components. This encompasses factors such as dielectric breakdown in capacitors, electromigration in semiconductors, and mechanical wear in connectors.

Thermal Cycling Effects: Thermal stress and ultimate failure can be caused by repeated heating and cooling. The objective of design strategies should be twofold: to minimize the impacts of thermal cycling or to incorporate measures for accommodating them without resulting in damage.

Preventive Maintenance and Monitoring: In maintaining long-term reliability, the incorporation of features for preventive maintenance, including critical parameter monitoring and early warning system implementation, proves beneficial.

Lifecycle Testing: To validate the long-term reliability of the design, extensive lifecycle testing, including stress testing and accelerated aging play a vital role. Identifying potential failure points and enabling design modifications before mass production are facilitated by this testing.

Compliance with Standards: Isolators can meet the rigorous reliability requirements of military applications or vehicular electronics by adhering to industry-specific standards such as MIL-STD for these sectors.

Managing Electromagnetic Interference (EMI)

Managing electromagnetic interference (EMI) is a crucial challenge in the design of digital isolators with integrated power. Due to the significant impact EMI can have on system performance, effective mitigation strategies are necessary.

EMI Sources and Impact on System Performance

Sources of EMI: Various sources can be the origin of EMI in electronic systems. Switching transients from power converters, clock signals from digital circuits, and motor drives are among the internal sources. Radio frequency interference from wireless devices, electrical surges from power lines, and electromagnetic fields from other equipment constitute the external sources.

Impact on Digital Isolators: EMI poses a threat to the operational efficiency of digital isolators. The presence of high-frequency interference may result in signal integrity concerns, ultimately culminating in data errors and system malfunctions. In instances of heightened severity, EMI can result in component failure by surpassing imposed voltage thresholds.

System-Wide Implications: In addition to its impact on individual components, EMI has the potential to diminish the overall performance of electronic systems. Such degradation encompasses decreased accuracy within data acquisition systems, operational instability in control systems, and communication errors in network interfaces.

EMI Mitigation Strategies

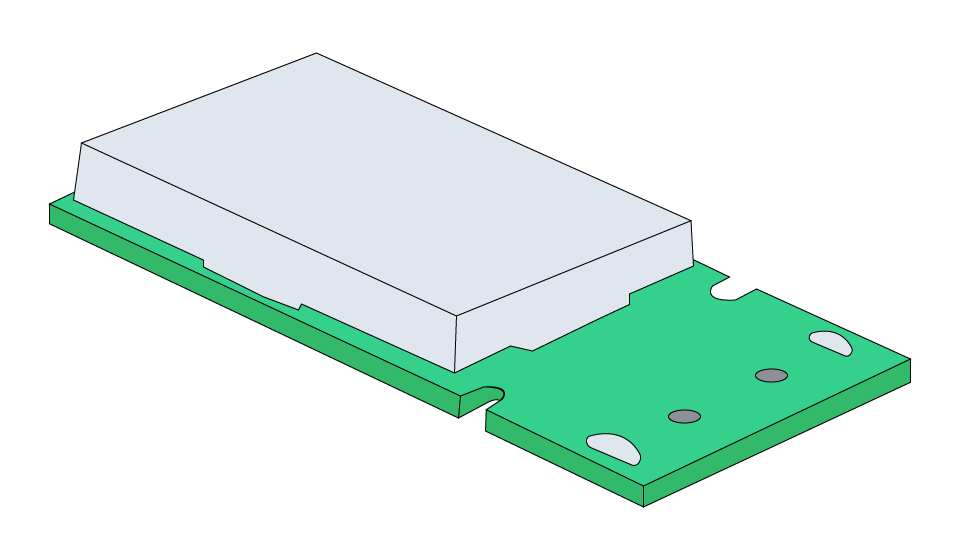

Shielding and Grounding: In the mitigation of EMI, it is crucial to employ effective shielding for sensitive components and adhere to proper grounding practices. Enclosing electronic circuits in conductive or magnetic materials constitutes shielding, whereas dissipating unwanted electromagnetic energy is facilitated by grounding.

Figure 1: EMI Shielding

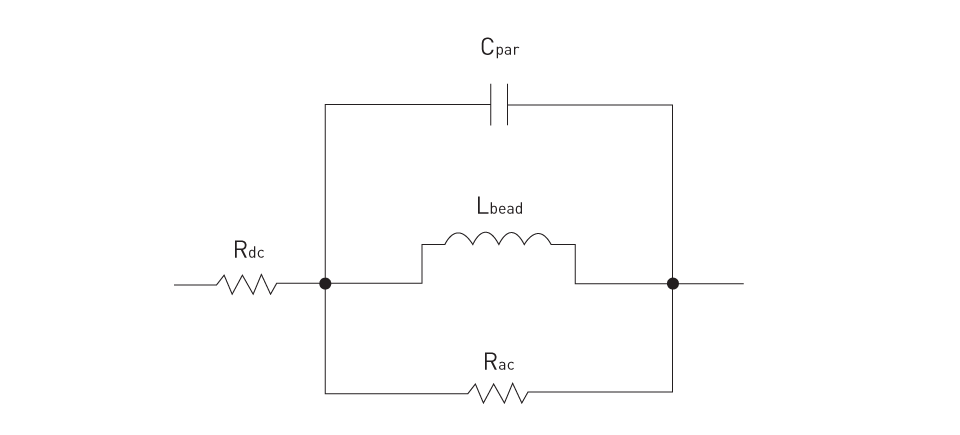

Filtering: The suppression of EMI can be achieved by implementing filters at critical points in the circuit. This involves integrating ferrite beads to filter out high-frequency noise and employing low-pass filters to block high-frequency noise.

Figure 2: Simplified Circuit Model for a Ferrite Bead

PCB Layout and Design: Minimizing EMI heavily relies on meticulous PCB layout and design. This encompasses loop area reduction, strategic component placement, utilization of differential signaling when feasible, and the establishment of distinct ground planes for digital and analog circuits.

Component Selection: Reducing the overall vulnerability of the system to EMI can be achieved by selecting components that are less susceptible to it or specifically designed for high-noise environments. In areas with substantial electromagnetic disturbances, components boasting higher immunity ratings are the preferred choice.

Compliance with EMC Standards: It is crucial to adhere to electromagnetic compatibility (EMC) standards, like FCC Part 15 or IEC 61000, which offer guidelines for EMI emissions and immunity. These standards ensure that electronic devices do not interfere with each other's function.

Routine Testing and Validation: Throughout the development process, consistent EMI testing and validation aid in the early identification and resolution of potential EMI issues. This involves both emissions testing and immunity testing, ensuring adherence to standards and dependable performance in real-world scenarios.

直接登录

创建新帐号