Operating Temperature and Cooling

An electric motor's performance, efficiency, and lifespan are greatly impacted by its operating temperature, a crucial factor to consider. As a consequence of converting electrical energy into mechanical energy, electric motors produce heat. Failure to effectively manage this heat can result in decreased efficiency, degradation of components, and potentially motor failure.

Heat Generation in Motors: Electric motors primarily generate heat from electrical resistance in the windings (known as I²R losses), magnetic hysteresis, and eddy current losses in the iron core. Additionally, friction in bearings and brushes (found in brushed motors) contributes to heat production. The equilibrium between the heat generated internally and the heat dissipated to its surroundings determines the temperature increase within a motor.

Impact of High Operating Temperature: A motor can suffer adverse effects from operating at elevated temperatures. Consequently, the motor's longevity diminishes as the degradation of insulation materials in windings accelerates at elevated temperatures. This heightened temperature accelerates the degradation of bearings and lubricants, elevating the likelihood of mechanical failures. Additionally, elevated temperatures can lead to the demagnetization of permanent magnets in brushless DC and specific AC motors.

Cooling Mechanisms: Motors utilize various cooling methods to manage heat. The most prevalent cooling techniques include:

- Self-Cooling: In smaller motors, heat is dissipated into the surrounding air through the exterior surface of the motor itself. This passive method relies on the motor's surface area and the surrounding air conditions for heat dissipation.

- Fan Cooling (External and Internal Fans): Built-in fans are a feature of many motors. To augment heat dispersion, these fans, whether affixed to the motor shaft or powered separately, propel air over the motor's surface or through internal passages.

- Liquid Cooling: Motors operating in high-temperature environments or those with high power requirements may utilize liquid cooling systems. Coolant systems, such as water or oil circulation, are employed to efficiently extract excess heat from the motor casing or internal cooling channels.

Monitoring and Control: Contemporary motor systems frequently integrate thermal protection devices and temperature sensors. Monitoring the motor's temperature, these sensors can activate alarms or shut down the motor if the temperature surpasses safe thresholds. Preventing damage from overheating, thermal protection is essential, especially in scenarios where motors endure heavy loads or elevated ambient temperatures.

Design Considerations: Thermal management is greatly influenced by motor design. Heat generation and dissipation are impacted by various factors, including material selection, winding design, and housing geometry. To ensure optimal performance and longevity, engineers must balance these design elements with the motor’s specific application.

Torque per Unit Volume

A crucial parameter in the design and selection of electric motors, is torque density, or torque per unit volume. It measures how efficiently a motor generates torque relative to its size. Applications where space and weight are limited, such as in aerospace, robotics, and portable electronic devices, place particular importance on this concept.

Dividing the torque produced by a motor by its volume determines torque density. Typically, it's denoted in Newton-meters per cubic meter (Nm/m³). A high torque density implies that a motor can generate considerable torque relative to its compact size. In design scenarios where space efficiency is paramount, motors with high torque density are often favored.

The torque density of a motor is influenced by several factors, which include:

Magnetic Materials: The torque density of a motor is significantly impacted by the choice of magnetic material used in its construction, especially in the rotor and stator. Enhancing torque density can be significantly achieved by materials possessing superior magnetic permeability and improved magnetic saturation properties, such as rare-earth magnets utilized in brushless DC motors.

Winding Design: A crucial role is played by the design of the windings in determining factors such as the type of wire used, winding density, and the winding method. Increased winding densities generally lead to greater torque densities, as a larger amount of copper within the motor can generate increased magnetic field strength within a specified volume.

Motor Design: Enhancing torque production per unit volume can be achieved through optimizing the magnetic flux path and refining the overall motor design, encompassing the geometry of both the rotor and stator, as well as aligning magnetic poles effectively.

Cooling Efficiency: By enabling the motor to withstand higher current densities without overheating, efficient cooling contributes to boosting torque density. This aspect can be further improved by employing advanced cooling methods, such as liquid cooling.

Impact of High Torque Density: Because they deliver greater power output within a smaller footprint, motors offering high torque density are beneficial. This is especially advantageous in compact, power-sensitive applications like electric vehicles, drones, and other similar contexts. A reduction in the overall weight of the system, a critical factor in portable and mobile applications, can result from high torque density.

Trade-offs: High torque density, although desirable, often entails compromises. The cost of the motor can be significantly raised by the utilization of high-performance materials such as rare-earth magnets. Furthermore, the management of heat generated by high power density becomes a critical aspect of design, as it can impact both the efficiency and lifespan of the motor.

Power per Unit Volume

In the context of motor design, selection, and application, comprehending the power per unit volume of electric motors is essential. This aspect holds particular importance in applications where both space constraints and high performance are key factors.

The amount of power a motor can deliver in relation to its size is quantified by power density, is known as power per unit volume. Expressed typically in watts per cubic meter (W/m³), it is defined as the motor's output power divided by its volume. In applications where both compactness and high power are essential, such as in aerospace, automotive, and robotics, a motor with high power density is an ideal choice. This indicates that the motor can deliver substantial power while occupying minimal space.

Several factors influence the power density of a motor, including:

Magnetic Materials: Utilizing advanced magnetic materials with increased flux density enables the delivery of high power in smaller motor sizes. For instance, employing rare-earth magnets plays a significant role in enhancing the power density.

Winding Design: The efficiency of converting electrical power into mechanical power is influenced by the arrangement and density of the windings. Power density can be enhanced by employing more compact and efficient winding designs.

Cooling Techniques: Improving power density can be achieved by implementing efficient cooling systems, which enable motors to operate at higher power levels without overheating. In this regard, advanced cooling techniques such as liquid cooling prove to be highly effective.

Specific Torque

The performance attributes of electric motors, especially specific torque and efficiency, are directly influenced by the dimensions of the motor in the domain of electric motor design and application. Engineers and designers must comprehend these effects dependent on size to optimize motor selection and application across various industrial and commercial sectors.

Specific Torque: The torque output of a motor relative to its size or mass is referred to as specific torque. Expressed typically in Newton-meters per kilogram (Nm/kg), it quantifies how effectively a motor can generate torque for its size. In applications where weight and space are constraining factors, such as in aerospace or portable electronic devices, this parameter holds particular significance.

- Miniaturization Impact: Attaining high specific torque can pose a greater challenge as motors decrease in size. The limited space available for winding and magnetic materials in miniaturized motors can restrict their capacity for generating torque.

- Material Innovations: The development of smaller motors with higher specific torque has been facilitated by advancements in materials technology, notably in high-strength magnets and lightweight, high-conductivity wire.

Efficiency and Motor Losses

Typically represented as a percentage, the efficiency of a motor is usually defined as the ratio of mechanical power output to electrical power input. Transforming a greater proportion of electrical energy into mechanical energy while minimizing losses characterizes motors with high efficiency. Motor efficiency is influenced by various factors, including electrical losses (such as copper losses in windings and iron losses in the core), mechanical losses (like friction in bearings), and stray load losses (including leakage inductance and aerodynamic drag).

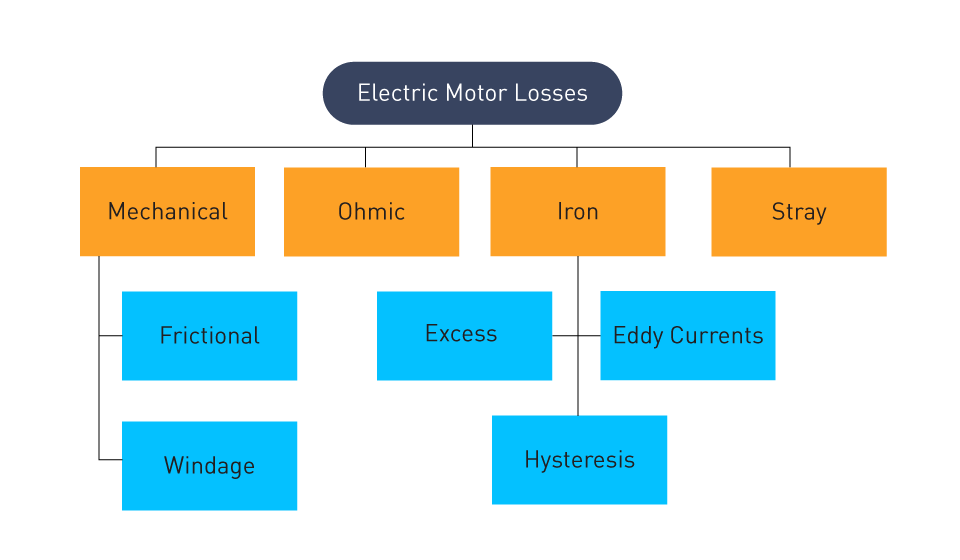

Figure 6: The Different Type of Motor Losses

Motor Losses:

- Ohmic Losses (Resistive Losses): The resistance found in the motor's windings contributes to these losses. A result of the inherent resistance of the material, energy is dissipated in the form of heat as current flows through the conductors. During high-load conditions, this type of loss becomes significant as it increases with the square of the current.

Mechanical Losses:

- Windage Losses: As the motor's rotor spins, these losses arise from air resistance. The design of the motor's enclosure and the rotor's speed influence windage losses.

- Frictional Losses: Due to friction between moving parts within the motor, such as bearings and brushes (in brushed motors), these losses occur. Frictional losses can be minimized through proper lubrication and regular maintenance.

Stray Load Losses: These losses lead to inefficiencies that are not directly accounted for in other categories, arising from non-ideal distributions of magnetic fields. Increasing with the load, stray load losses can be affected by factors such as manufacturing inconsistencies and asymmetries in the motor's construction.

Iron Losses: Related to the motor's magnetic core, these losses can be further categorized into:

- Hysteresis Losses: Energy loss occurs due to the lag in the alignment of the magnetic domains within the iron core when the motor's magnetic field reverses with each cycle of the AC current. For constructing the motor core, materials with low hysteresis loss are preferred.

- Eddy Current Losses: These arise when the altering magnetic field induces currents within the core material itself. Heat generation and energy loss result from these induced currents. Eddy current losses can be reduced by laminating the core or utilizing materials with high electrical resistivity.

- Excess Losses: Under load conditions, these are additional iron losses that arise from non-uniform distribution of the magnetic field and saturation effects in the core.

Efficiency Standards and Regulations:

Several global standards and regulations, such as those established by the International Electrotechnical Commission (IEC) and the U.S. Department of Energy (DOE), have been implemented to promote the adoption of high-efficiency motors in industrial and commercial contexts, acknowledging the importance of efficiency. Here are the respective numbers of some of the most widely recognized standards:

IEC 60034-30: Specifies efficiency classes for cage-induction motors, single-speed, three-phase. It introduces efficiency classes IE1 (Standard Efficiency), IE2 (High Efficiency), IE3 (Premium Efficiency), and IE4 (Super Premium Efficiency), known as the IE efficiency classes.

IEEE 841: In petroleum and chemical industry applications, it targets severe-duty totally enclosed fan-cooled (TEFC) motors, emphasizing performance, reliability, and energy efficiency.

NEMA MG 1: This standard, published by the National Electrical Manufacturers Association, furnishes manufacturing specifications for electric motors in North America, inclusive of energy efficiency standards aligned with those set by the DOE.

EN 50598-2: Concentrating on ecodesign requirements for power drive systems, motor starters, power electronics, and their associated applications, this European standard contributes to bolstering overall energy efficiency and environmental sustainability.

Regulation (EU) 2019/1781: Within the European Union, it establishes minimum energy performance standards (MEPS) for electric motors and variable speed drives, encompassing various motor types and sizes, with the goal of enhancing energy efficiency in industrial settings.

Size-Dependent Losses: Mainly attributable to reduced relative losses, larger motors typically exhibit higher efficiency. Enhanced winding arrangements and superior heat dissipation capacities, facilitated by larger sizes, result in decreased electrical and thermal losses. Conversely, smaller motors might encounter comparatively elevated losses because of limitations in design and material utilization, impacting their efficiency.

Design Optimization: To address these challenges in smaller motors, it becomes crucial to optimize design parameters like winding density, minimizing air gaps, and selecting appropriate materials. In compact motor designs, maintaining high efficiency can be supported by utilizing high-quality magnetic materials and implementing efficient cooling techniques.

Application-Specific Trade-offs: It's essential to weigh these advantages against potential reductions in efficiency and specific torque, while smaller motors may provide benefits in terms of space conservation and weight reduction. When selecting motor size, it's important to take into account the specific needs of the application, which include load characteristics, space limitations, and energy efficiency considerations. The choice of motor size thus involves considering the application's specific requirements.

Rated Voltage

In the context of electric motor operation, the concept of rated voltage is essential. The particular voltage at which a motor is engineered to function most efficiently and effectively is denoted by rated voltage. For both the longevity and performance of the motor, this parameter is vital.

The designated voltage level at which a motor can be expected to deliver its rated power output without undue stress or overheating is known as the rated voltage. Based on the design and intended application of the motor, it is a key specification provided by the manufacturer. Ensuring optimal performance, including torque and speed characteristics, and minimizing wear on the motor's components is achieved by operating a motor at its rated voltage.

Voltage Range and Motor Operation

Deviations can result in significant consequences, although motors can typically function somewhat outside their rated voltage:

Under-Voltage Operation: A reduction in torque output can occur when running a motor at a voltage lower than its rated voltage, making it unable to drive its load effectively. Drawing higher current to uphold its torque can also result from this, potentially leading to increased losses and overheating in the motor.

Over-Voltage Operation: On the other hand, running a motor at a voltage higher than its rated voltage can result in excessive speed and potentially higher mechanical stress on the motor. Accelerating insulation breakdown and increasing the risk of electrical failure can also result from this.

Voltage and Motor Types

Across different types of motors, there is significant variation in the rated voltage:

- DC Motors: In small, battery-operated motors, the rated voltages usually range from a few volts to several hundred volts in large industrial motors. For the overall control of the motor, the rated voltage plays a crucial role in the commutation process.

- AC Motors: In the United States, standard power supply voltages like 120V, 240V, or 480V are often aligned with the rated voltage for AC motors, while in Europe, it is typically 230V and 400V. In industrial settings, three-phase AC motors, which are commonly utilized, will have rated voltages that correspond to three-phase power systems.

- Stepper Motors: In high-speed or precision applications, precision motors have specific rated voltages, but they are typically operated with multiples of their rated voltage to compensate for the extended current build-up time resulting from the motor's winding inductance. The motor driver circuit applies a chopped voltage with a higher frequency, ensuring that the current in the motor does not surpass its rated limits, making this achievable. For instance, a stepper motor with a rated voltage of 4.8V could be powered by 12V or 24V sources.

Voltage and Motor Control Systems: It is essential to keep the voltage within the rated range in systems where speed or torque control is necessary. Speed controllers for DC motors and variable frequency drives (VFDs) for AC motors are engineered to provide the motor with its rated voltage even under fluctuating load conditions.

Short Term Overload

The ability of electric motors to operate briefly above their rated capacity without sustaining damage or experiencing a significant reduction in lifespan is known as short-term overload. This characteristic is vital for scenarios in which motors might encounter intermittent spikes in load requirements.

When the motor is required to produce a level of torque or power that exceeds its normal operating capacity, overload situations arise in electric motor operation. Such occurrences frequently take place during start-up (particularly for heavy loads), sudden acceleration, or when faced with an unforeseen increase in load.

Implications of Overload: These situations impose extra strain on different motor components, resulting in heightened heat generation, although electric motors can typically manage short-term overloads. Extended duration of the overload or its severity can lead to overheating, resulting in insulation breakdown, mechanical wear, and potentially, motor failure.

Motor Design and Overload Capacity

A motor's capacity to endure short-term overload relies on its design and construction. Vital factors encompass:

Thermal Capacity: The capability of a motor to disperse heat is vital for enduring overload situations. Motors that are engineered with premium-grade insulation materials and superior cooling techniques can withstand increased levels of short-term overload.

Mechanical Strength: The motor's mechanical elements, including bearings and shafts, must be sufficiently robust to withstand the heightened mechanical stresses experienced during overload conditions.

Safety Margins: Manufacturers frequently incorporate a safety margin above the rated capacity when designing motors. The extent to which the motor can manage overload without risk is typically indicated in the motor's documentation through this margin, as specified.

Overload Protection Devices

Various protection devices are employed to safeguard motors against the detrimental impacts of overload conditions.

Thermal Overload Relays: To prevent overheating, these relays are engineered to detect excessive current draw, which is often associated with overload conditions, and cut off the power supply.

Circuit Breakers and Fuses: Short-circuit conditions, which can result in severe overload, are safeguarded against by these devices.

Electronic Protection: Electronic sensors in advanced motor control systems monitor motor parameters such as current, voltage, and temperature, offering precise protection against overload conditions.

Symptoms of Damaged Motor

Tripping Circuit Breakers or Blowing Fuses: As the electrical system tries to protect itself from overheating and potential fires, frequent tripping of circuit breakers or blowing fuses can occur due to increased current demand from shorted windings or compromised insulation.

Excessive Heat Generation: Increased surface temperatures can often be felt as overloaded motors run hotter than their design specifications permit. Deterioration of insulation on windings, leading to failure, can result from overheating.

Unusual Noises: Unusual sounds like humming, buzzing, or grinding might be emitted by a motor that has sustained damage from overload. Resulting from distorted windings, bearing failures, or mechanical imbalances due to thermal expansion of internal components, these noises can be heard.

Reduced Performance: Reduced efficiency and performance may be observed in an overloaded motor. Indications of potential damage to the windings or rotor include decreased speed, lower torque output, and sluggish response to load changes.

Visible Signs of Damage: Discoloration of the windings, insulation breakdown, or deformation of motor components may be revealed through physical inspection. This type of damage usually stems from excessive heat accumulation during overload conditions.

Increased Vibration: Overload-induced damage can misalign the motor's rotor, cause bearing wear, or lead to other mechanical problems, resulting in increased vibration levels. These issues can be detected early through vibration analysis.

Application Considerations

Choosing a motor with suitable overload capacity is crucial in applications where short-term overloads are anticipated. Furthermore, understanding the frequency and duration of potential overloads aids in selecting the appropriate protection devices, thereby ensuring the motor’s reliability and longevity.

直接登录

创建新帐号