New Materials and Motor Designs

The unrelenting pursuit of development in motor technology has resulted in considerable breakthroughs in the materials that are used for the building of motors as well as in the design of motors in general. Not only do these advancements improve performance, but they also contribute to the development of motors that are more efficient and smaller in size.

Exploration of Advanced Materials in Motor Construction

New materials are becoming increasingly popular among motor vehicle producers as a means of improving their products' functionality and effectiveness. The magnetic field strength is being increased by the utilization of cutting-edge materials such as high-performance magnets built from neodymium. This directly results in increased torque and efficiency in a more compact container. When it comes to high-power applications and settings that provide major thermal issues, the utilization of composite materials and ceramics is growing. The goal is to reduce weight and enhance thermal management, two crucial aspects.

Among the examples are:

High-temperature superconductors (HTS): Some of the most recent motor designs use high-temperature superconductors (HTS) to significantly reduce electrical resistance and increase motor efficiency, especially in applications that demand very high power densities.

- Critical Temperature (Tc): High-temperature superconductors function at temperatures that are higher than 77 Kelvin (-196 degrees Celsius), which is the boiling point of liquid nitrogen. This temperature is considered significantly higher than that of conventional superconductors, which require cooling to near absolute zero. Because of this higher critical temperature, it is possible to implement cooling technologies that are more practical, such as liquid nitrogen, rather than helium systems, which are more expensive.

- Critical Magnetic Field (Hc): High-temperature superconducting (HTS) materials have the ability to preserve their superconducting properties even when subjected to extremely high magnetic fields, which sometimes surpass several Tesla. This property is crucial in motor applications that generate intense magnetic fields to efficiently produce torque.

- Current Density (Jc): HTS materials can carry a current density of Jc, which is extremely high, without experiencing any resistance. This quality allows for the creation of smaller and more compact motor designs, while also enabling the delivery of larger power densities. This is a key feature for high-performance applications such as electric vehicles and airplanes.

Soft magnetic composite (SMC) materials: Motor cores use materials classified as soft magnetic composites (SMC). The superior magnetic characteristics of these materials aid in reducing the eddy current losses typically seen in conventionally laminated steel cores.

- Permeability: High magnetic permeability in SMC materials enhances the magnetic flux density within the motor's structure. This feature makes it possible to achieve higher levels of efficiency in electromagnetic conversion.

- Core Losses: SMCs, in comparison to standard laminated cores, have lower eddy current losses at high frequencies. This is achieved through core losses. This situation has arisen due to the unique structure of insulated iron particles, which limit the passage of eddy currents.

- Thermal Conductivity: The thermal conductivity of SMCs is typically sufficient to effectively dissipate the heat generated in high-speed motor applications, despite the fact that it is lower than the thermal conductivity of laminated steels.

Innovative Designs that Enhance Performance and Reduce Size

Innovations in motor design constantly shape the motor industry. Conventional designs such as coreless motors and printed-armature motors are undergoing rethinking to reduce size and enhance performance. These designs either completely eliminate the motor's rotor construction or make significant modifications to it. This significantly reduces the motor's inertia and weight, allowing it to accelerate more quickly, achieve higher efficiency, and reduce its overall proportions.

Among the examples are:

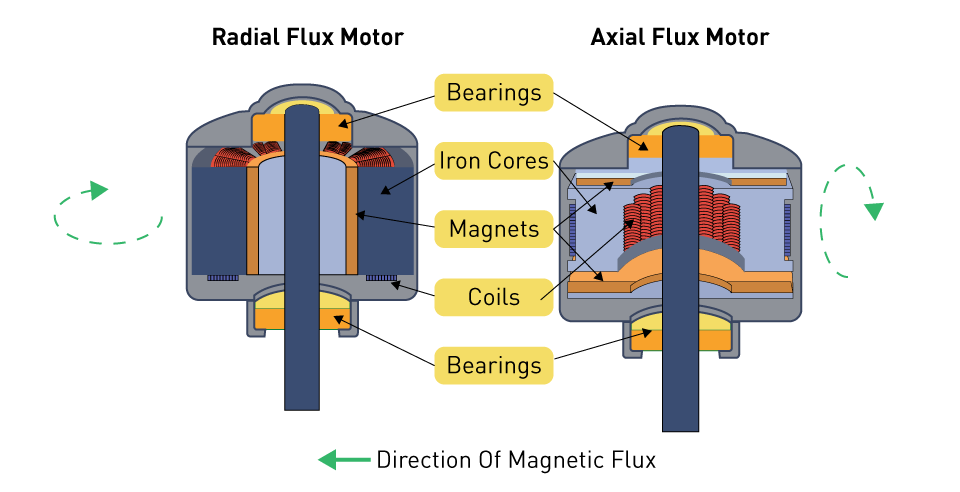

Axial flux motors: Unlike conventional radial flux motors, axial flux motors have a flatter and more disc-like shape. This might be advantageous in situations where space is at a premium. These motors have a high torque-to-weight ratio, which is especially beneficial for applications in the aerospace and automotive industries.

Figure 1: Radial Flux versus Axial Flux Motor

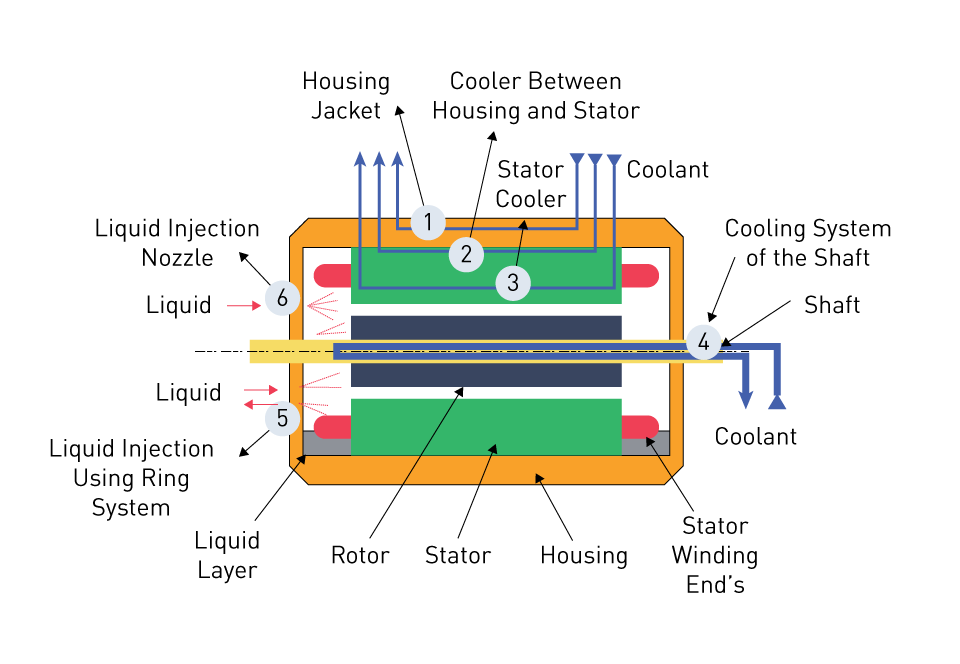

Integrated cooling systems: New motor designs incorporate advanced cooling techniques directly into the motor's construction. These techniques include liquid-cooled stators or rotor cooling channels, which help regulate heat more effectively and increase the motor's performance.

Figure 2: Liquid cooled stator concept

Smart Motors and IoT Integration

The incorporation of the Internet of Things (IoT) and smart technologies into motor systems is a revolutionary step forward in motor technology. This development ushers in a new era of operational efficiency and the ability to do predictive maintenance.

Incorporation of IoT for Predictive Maintenance and Efficiency

Smart motors equipped with Internet of Things technologies have the potential to greatly improve operating efficiency through real-time data analytics and predictive maintenance. These motors, equipped with sensors throughout their construction, monitor a number of characteristics, including temperature, vibration, and load conditions. By evaluating this data, Internet of Things (IoT)-enabled motors are able to identify probable failures before they occur, which in turn reduces downtime and maintenance costs. This preventative approach to maintenance guarantees motor servicing only when necessary, thereby optimizing maintenance schedules and extending the equipment's lifespan. Among the examples are:

Vibration sensors: When the motor is operating, vibration sensors identify vibrations that are not typical. These vibrations may be an indication of issues such as misalignment or bearing failure.

Temperature monitors: These sensors have the ability to notify operators if particular components approach critical temperature thresholds, which could result in the motor overheating and eventually failing.

How Smart Motors are Changing Operation and Monitoring

Advanced monitoring and automation systems enable smart motors to provide more operational insights and improved control functions. Smart motors also offer other advantages. More comprehensive automation systems often include these motors, enabling real-time adjustments to operational parameters. For instance, these systems can automatically modify the speed and torque settings according to task requirements, eliminating the need for human intervention. This facilitates the optimization of energy consumption and the reduction of operational expenses. Among the examples are:

Remote monitoring: Data from IoT sensors enables operators to conduct remote monitoring of motor performance from a central location. When it comes to huge industrial operations where human monitoring is completely impracticable, this functionality is really essential.

Automated decision-making: Thanks to sophisticated algorithms, smart motors can independently make decisions about their operation. For example, they might slow down in order to conserve energy during periods of low demand, or they might adjust the operation settings in response to variations in the quality of the power supply.

High-Efficiency Motor Technologies

Substantial breakthroughs in high-efficiency motor technology are occurring due to the growing need for energy-efficient solutions. Not only do these advancements significantly reduce energy consumption, but they also significantly promote sustainability and reduce operational costs in various industries.

Developments Aimed at Increasing Motor Efficiency

Efforts to improve motor efficiency have resulted in the development of a wide range of cutting-edge technology and design enhancements. These include advancements in the methods of winding motors, the utilization of insulation materials of superior quality, and the implementation of manufacturing procedures that are more exact, thereby reducing the amount of electrical and mechanical losses. People are increasingly using variable-speed drives (VSDs) to precisely match the motor's speed with the load requirements, significantly reducing energy waste.

Improved winding layouts: Improved winding design can reduce copper losses, a major cause of electrical inefficiency in motors. The concentrated winding layout is an example of a winding layout that improves the efficiency of the motor. Concentrated windings, which are also referred to as tooth coil windings, include positioning the winding coils directly around the stator teeth. In contrast, the standard motor design often distributes the winding coils across as many teeth as possible.

Advanced magnetic materials: High-grade magnetic materials reduce the amount of hysteresis and eddy current losses that are typical in conventional motors.

Next-Generation Motor Technologies

Superconducting motors and motors that make use of soft magnetic composite (SMC) materials are two of the most promising technologies for the advancement of motor technology in the next generation. Although they are currently mostly in the experimental and development stages, superconducting motors offer nearly zero electrical resistance at extremely low temperatures. This significantly boosts efficiency by reducing the amount of energy lost as heat. During this time, motors constructed with soft magnetic materials have the advantage of lower core losses and a larger saturation magnetization, both of which contribute to an increase in their efficiency at higher frequencies.

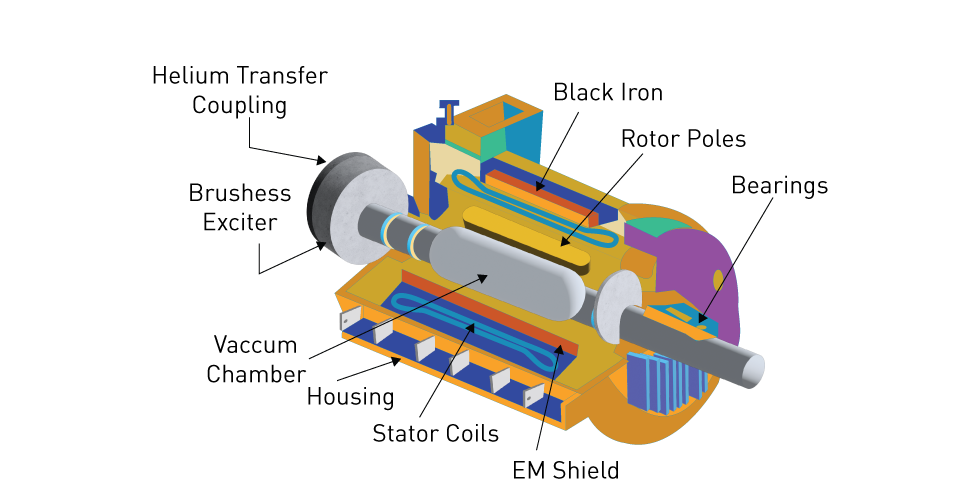

Superconducting motors: These motors make use of superconducting wires, which are able to carry much bigger currents than regular wires. As a result, they are able to generate extremely high magnetic fields without the heat losses that are associated with normal materials.

Figure 3: Example Construction of a Superconducting Motor

Soft magnetic composite motors: SMCs, or soft magnetic composite motors, are able to distribute magnetic flux in three dimensions, which not only enhances the motor's performance but also makes it possible to create motors that are more compact.

直接登录

创建新帐号