Introduction to Battery Management Systems (BMS)

Definition of BMS

A battery pack's performance, use, and safety are monitored and managed by a battery management system (BMS), an intelligent electronic device. It is a crucial component of contemporary battery technology, especially in uses for lithium-ion batteries. The BMS is in charge of a number of duties, including keeping track of the temperature, voltage, state of health (SOH), and state of charge (SOC) of each cell in a battery pack. It also offers defense against situations that could harm the battery, such as overcharging, over-discharging, short circuits, and thermal runaway.

Historical Background

Along with the advancement of rechargeable battery technologies came the necessity for battery management. Lead-acid batteries were commonly utilized in the late 19th and early 20th centuries. Simple voltage regulators were used to prevent the overcharging that might lead to battery failure in early batteries.

Since nickel-cadmium (NiCd) batteries were more sensitive to charging and discharging circumstances, more sophisticated management was required with their introduction in the 1960s. The overcharge protection circuits were essentially where the idea of a BMS first emerged.

The early 1990s saw the commercialization of lithium-ion batteries, which was a significant turning point in BMS's history. Higher energy density was provided by lithium-ion batteries, but because of their sensitivity to overcharging and vulnerability to thermal runaway, they needed more sophisticated management systems.

The complexity and significance of BMS significantly increased in the twenty-first century with the popularity of electric vehicles and renewable energy storage. Modern BMS are able to perform complex tasks like cell balancing, data recording, diagnostics, and system communication in addition to protecting and monitoring battery packs.

BMS are now a crucial part of making sure batteries operate safely, dependably, and effectively in a variety of applications, from electric cars and portable devices to grid energy storage systems. BMSs are anticipated to advance even further as battery technology develops, adding capabilities like advanced heat management, remote monitoring, and predictive analytics.

The Need for BMS in Battery-Operated Systems

BMS is essential for maintaining the performance, security, and durability of battery-operated systems. The necessity of BMS in these systems can be attributed to a number of factors:

Safety

The protection of the battery system is one of the main goals of using a BMS. Lithium-ion batteries in particular risk becoming volatile if improper care is not taken with them. Thermal runaway, which can result in the battery catching fire or exploding can be brought on by overcharging, over-discharging, high current, or operating outside of the permitted temperature range. A BMS continuously monitors the operating circumstances and acts to stop harmful situations by cutting off the battery or changing the charge/discharge rates.

Reliability and Longevity

The longevity and dependability of the battery are considerably enhanced by a BMS. The BMS controls battery operations within the ideal range by continuously monitoring the SOC, SOH, and other crucial factors. This entails safeguarding against deep discharges and controlling the charge cycles to reduce capacity loss and deterioration over time, hence extending the battery's usable life.

In order to maximize the runtime of battery-operated equipment, the BMS is essential. It guarantees that the battery is used to its maximum potential while maintaining long-term performance and safety. Maximizing runtime is crucial for critical applications like medical devices or uninterruptible power supply, and the BMS makes sure that energy is used effectively.

Cost

The installation of a BMS may increase the battery system's initial cost, but it reduces expenditures over time. The BMS lowers the frequency and expenses of battery replacements and maintenance by extending battery life and lowering the danger of battery failure. A BMS can also avoid harm to other components and liability related to accidents by avoiding catastrophic failures.

Optimizing Tradeoffs for any Specific Application

The needs for energy storage, power delivery, safety, and longevity vary depending on the application. For instance, whereas an energy storage system for a solar panel might emphasize energy capacity, an electric car may demand a high power output. To optimize these trade-offs in accordance with the unique demands of each application, a BMS is essential. A BMS may balance delivering high power, maximizing energy storage, guaranteeing safety, and extending battery life as needed for a specific use case by intelligently controlling charging, discharging, and operating circumstances.

Key Function of BMS

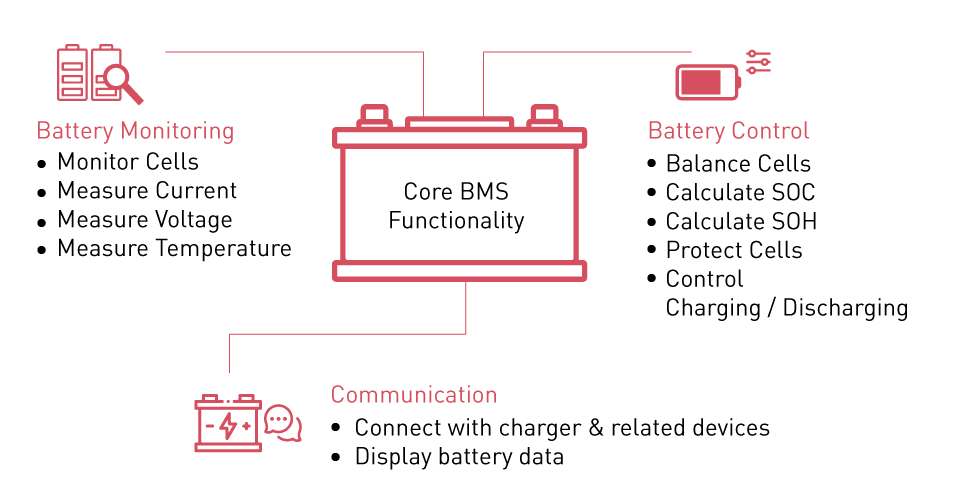

Figure 1: BMS functionality

Battery Management System (BMS) are essential for the best performance of battery packs. They achieve this by performing a number of tasks, such as monitoring, protecting, balancing, and reporting. The performance, longevity, and safety of battery systems are all guaranteed by each of these functions.

Monitoring

A BMS's control and management operations are built on top of monitoring. It is essential to continuously monitor important variables including voltage, current, temperature, and SOC. Each cell or group of cells in the battery pack is continuously monitored by the BMS to make sure they are operating within the specified parameters. Monitoring is crucial for real-time management as well as for gathering information that may be used to forecast the battery pack's future performance and health.

Protection

One of the primary responsibilities of a Battery Management System (BMS) is to safeguard the battery and the system as a whole against conditions that could potentially cause harm or present safety hazards. The BMS carries out protective actions to counteract scenarios such as overcharging, deep discharging, overcurrent, short-circuits, and overheating. For example, if the voltage across a cell surpasses a specific threshold, indicating overcharging, the BMS may disconnect the charging circuit or divert the current to prevent further charging of that particular cell.

Balancing

Equalization is a crucial task carried out by the BMS to guarantee a uniform State of Charge (SOC) among all cells within a battery pack. In a series configuration, even slight disparities in individual cell capacities or impedance can lead to imbalances over time. Equalization can be accomplished through either passive or active methods. Passive equalization entails dissipating excess energy in the form of heat in cells with a high SOC, while active equalization involves transferring charge from cells with higher charge levels to those with lower levels. This process ensures that the battery pack can utilize its entire capacity and contributes to prolonging the overall lifespan of the battery.

Reporting

Reporting includes delivering pertinent facts and information to the user or other systems. A BMS transmits crucial data, including the SOC, SOH, and any fault circumstances, through reporting. This data can be utilized to provide data to other systems for control and decision-making, as well as to inform the user of the battery's present condition. For instance, in electric vehicles, the BMS interacts with the central control unit to provide data on the battery pack's condition, which might affect how the vehicle runs.

直接登录

创建新帐号