Introduction to Starting Systems

From a crucially singular moment- ignition, the symphony of mechanical components within a vehicle harmonizes. The responsibility of initiating the motion, both literally and symbolically, falls on the vehicle's starting system, igniting that initial spark. Starting system serves as the pivotal element orchestrating a smooth shift from a stationary vehicle to one brimming with vitality and hence a thorough understanding of this system holds paramount importance for automotive engineers.

Role and Importance of Starting Systems in Vehicles

Fundamental Purpose: In the engine, the beginning system’s role is to transform electrical energy from the battery into mechanical energy at the most basic level. This marks the inception of the engine's functionality, paving the way for subsequent combustion processes that propel the vehicle forward.

Significance: A vehicle’s autonomous operation is ensured by the starting system. In the absence of a dependable starting system, drivers would be compelled to seek external sources or alternative methods to activate the engine, greatly restricting the autonomy and convenience associated with using automobiles. Combining the battery's stored electrical energy with the engine's mechanical processes, it acts as a bridge between the vehicle’s electrical and mechanical realms. A starting system that operates effectively guarantees seamless engine ignition, enhances fuel efficiency right from the initial revolution, and reduces the wear and tear experienced by engine components.

Main Components of a Starting System

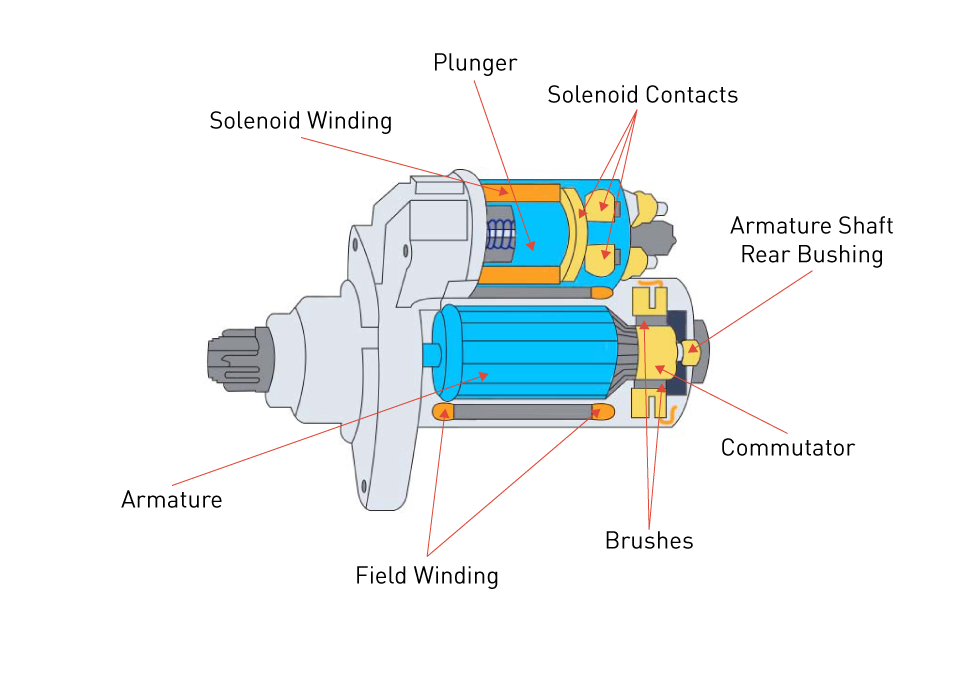

Figure 1: Main Components of a Starting Module

Battery: Battery is the primary electrical energy source that provides the required current to the starter motor. The battery plays a crucial role and needs sufficient capacity to ensure the engine can start, particularly in challenging conditions such as extreme cold.

Starter Motor: It is present at the center of the starting system. A high-torque, short-duration electric motor known as the starter motor is responsible for rotating the engine's crankshaft, setting in motion the engine's cycles until it can run independently. Engagement occurs as the starter motor connects a small pinion gear with a larger ring gear located on the engine's flywheel.

Starter Solenoid (or Starter Relay): The solenoid acts as a powerful switch and engages the starter motor’s pinion gear with the flywheel and combines the motor to the battery, enabling high current to flow into the starter motor. With its dual functionality, the solenoid ensures the motor operates solely when engaged with the flywheel, thereby averting potential damage.

Ignition Switch: It acts as an interface between the starting system and the driver. The ignition switch activates the starter solenoid when turned to the “start” position, which then powers the starter motor.

Neutral Safety Switch (for Automatic Transmissions) or Clutch Safety Switch (for Manual Transmissions): The vehicle can only be started when the clutch is depressed (for manual transmissions) or in "neutral" or "park" (for automatic transmissions). This safety measure ensures that the vehicle remains stationary and prevents any sudden forward or backward movement upon ignition.

Fundamentally, the starting system serves as the guardian controlling the operation of an automobile. Every journey starts with an efficient, reliable, and safe ignition and it is a synchronized balance between electrical and mechanical parts. With the advancement of technologies and the increasing sophistication of vehicles, the complexities of starting systems will similarly progress, requiring ongoing comprehension and innovation.

Operation of a Typical Starting System

Within a matter of seconds, the functioning of a conventional starting system orchestrates a remarkable synchronization of mechanical and electrical events. To those unfamiliar with the process, starting the engine might appear immediate and uncomplicated: simply turning a key or pressing a button, and the engine springs to life. However, the complicated sequence of works lies under this simplicity.

Sequence of Operations in Starting an Engine

Activation of Ignition Switch: When the driver turns the ignition switch to the ‘start’ position, the process commences. Via ignition circuit, this transmits an electrical signal.

Safety Checks: The vehicle is in a safe working state and is ensured by safety interlocks such as the clutch safety switch (in manuals), or neutral safety switch (in automatic transmissions) before the engine starts.

Starter Solenoid Engagement: The starter solenoid is a powerful relay that can manage the high current requirements of the starter motor and it is activated by the ignition switch’s signal.

Drive Mechanism Deployment: At the same time, the solenoid activates the drive mechanism, propelling the starter motor's pinion gear to interlock with the ring gear on the engine's flywheel. The starter motor's torque will be transferred to the engine and ensured by this mechanical engagement.

Starter Motor Activation: The solenoid now combines the starter motor to the battery with the gears engaged, enabling it to draw the required current. Cranking the engine, the starter motor starts turning.

Engine Ignition: Engine draws in air-fuel mixture as it cranks. Upon compression of the mixture, the ignition system activates the spark plugs, leading to the ignition of the mixture. The engine starts to operate independently.

Disengagement: The driver releases the ignition switch from the ‘start’ position once the engine is operating on its own. When this happens, it interrupts the initial circuit, causing the solenoid to lose power, consequently disengaging the pinion gear from the flywheel and disconnecting the starter motor from the battery.

Troubleshooting and Maintenance of Starting Systems

Ensuring a dependable engine start is a cornerstone of the automotive journey. Nevertheless, wear, deterioration, and malfunctions are unavoidable in both mechanical and electrical systems over time. A proficient automotive engineer or technician needs to comprehend potential issues and possess expertise in diagnostic methods for swift and efficient repairs.

Common Issues with Starting Systems

No Crank, No Start: When the engine fails to turn over and no sound is audible, it might suggest various issues such as a depleted battery, a defective ignition switch, or a malfunctioning starter motor.

Crank, No Start: When the engine cranks but doesn't start, it could signal potential problems beyond the starting system, such as issues related to fuel delivery or problems within the ignition system.

Intermittent Cranking: Intermittent engine turnover could result from worn-out components like starter solenoids, poor electrical connections, or a declining battery, among potential causes.

Grinding Noises: Usually, this occurs when the pinion gear fails to engage correctly with the flywheel. Potential causes could be a defective solenoid or a worn-out pinion gear.

Frequent Overheating of the Starter Motor: Extended cranking might suggest underlying issues elsewhere in the engine that could be preventing a successful start.

Solenoid Click but No Start: The audible click confirms the proper working of solenoid, yet the absence of engine turnover could suggest a malfunctioning starter motor.

Diagnostic Techniques and Repairs

Battery Test: It is critical to make sure that the battery is in good health before diving deep into the starting system. To measure the battery voltage, a multimeter is a great option. Usually, 12.6V must be a well-charged battery reading.

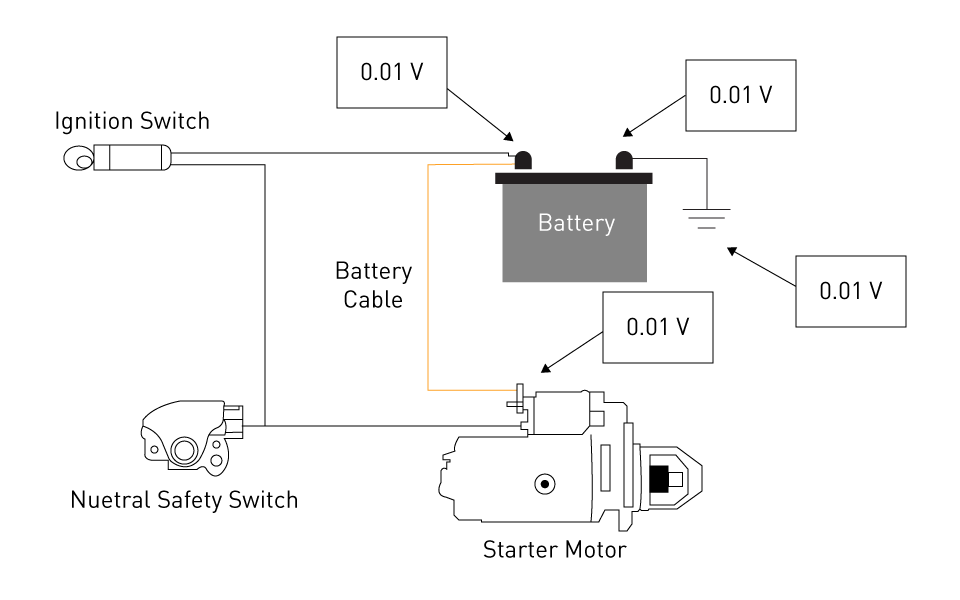

Voltage Drop Test: Poor electrical connections are identified by this test. One can estimate the voltage drop during cranking by putting multimeter leads on the cable end and the battery terminal. Poor connections are indicated by high readings.

Figure 2: Typical Voltage Drops of the Starting System

Starter Draw Test: During cranking, the amount of current drawn by the starter motor is estimated by the starter draw test. An indication of a malfunctioning starter motor could be an excessive draw of current. It compares the measured current against the manufacturer’s specification.

Solenoid Activation Test: One can check its operation by bypassing the ignition switch and applying voltage directly to the solenoid. When operational, the solenoid will emit a clicking sound and transmit power to the starter motor.

Physical Inspection: Issues such as loose connections, damaged parts, or corroded terminals can sometimes be revealed by a visual check.

Replacement and Repairs: The repairing of the faulty starter motor or solenoid entails a replacement. Nonetheless, resolving issues might also involve cleaning and securing connections or substituting worn-out elements such as brushes within the starter motor.

In summation, despite its robustness, the starting system is not immune to wear and faults. Employing a methodical diagnostic approach alongside a comprehensive grasp of the system guarantees vehicle reliability and the prompt resolution of any issues. To prevent numerous common starting problems, consistent preventive maintenance, including regular battery examinations and terminal cleaning can be used effectively.

Advances in Starting Systems

Progression in starting systems reflects the industry’s drive towards convenience, efficiency, and sustainability in the rapidly evolving automotive landscape. Numerous innovative starting technologies have been developed with the aim of enhancing the vehicle user experience and lessening environmental impact.

Start-Stop Systems

Definition and Purpose: Automatically shutting off the engine when the vehicle is stationary, such as at traffic lights, and restarting it when the driver is ready to move, start-stop system is employed. It primarily focuses on diminishing fuel consumption and emissions, especially in urban driving conditions.

Operation: The start-stop system is managed by the engine control unit (ECU) and depends on a few crucial sensors. The vehicle condition (stationary or moving) is detected by the speed sensors. Sensors in the brake pedal and clutch pedal communicate the vehicle's intention to stop or initiate movement. Contemporary systems integrate "Fly-by-wire" throttle control, an electronic substitute for conventional mechanical linkages. In controlling engine restarts, this adaptation provides faster response times and enhanced precision. Moreover, the system monitors the battery State-of-Charge to ensure adequate power for a restart. For improved performance and comfort, the system might delay activation under specific conditions, such as during a cold engine start.

Benefits: Start-stop systems minimize engine wear during idling periods and diminish noise pollution in urban localities, along with evident fuel conservation and decreased emissions.

Integrated Starter Generators (ISGs)

Concept: The functionalities of an alternator and a started motor are combined by the ISGs into a single unit. In the mild-hybrid vehicles, they serve a critical role.

Functionality: Directly linked to the engine's crankshaft, Integrated Starter Generators (ISGs) can initiate the engine almost silently and notably quicker than conventional starters. Moreover, the ISG can regenerate energy, storing it within the vehicle's battery while decelerating or braking. Let's examine a standard electrical system-level diagram for MHEV (Mild Hybrid Electric Vehicle) automobiles:

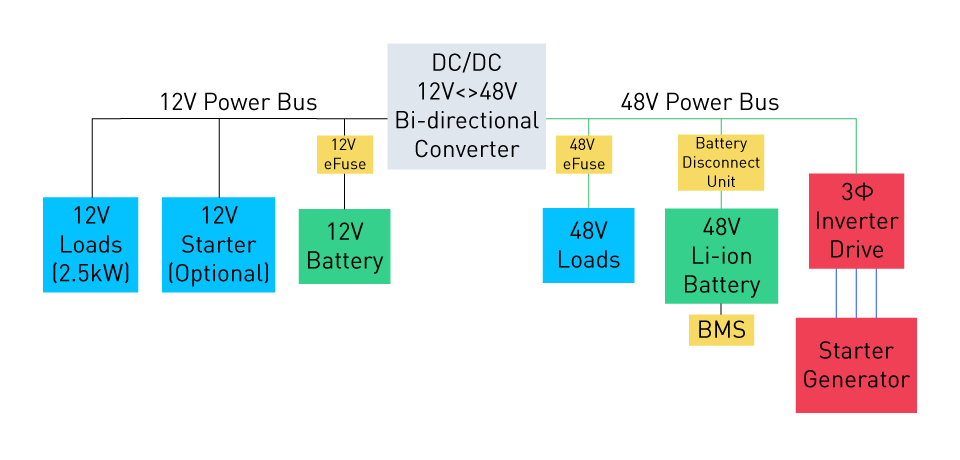

Figure 3: MHEV Electrical System Level Diagram

The 3-phase inverter drives the starter generator, which is connected to the 48V bus located on the right side. Each time the ICE engine initiates, the Starter Generator operates as a motor, sourcing power from the 48V bus. The starter generator feeds back power to the 48V bus when the ICE engine is running. The ISG and the 48V battery (see Figure 3), jointly supply input to the DC/DC converter. This converter powers the 12V system while also charging the 12V battery.

When the 48V battery is absent in systems, initiating the ISG requires the DC/DC converter to initially elevate the 12V voltage to 48V. This boosted voltage is then used to provide power to the Inverter Driver.

Advantages: Particularly in stop-and-go traffic situations, Integrated Starter Generators (ISGs) facilitate quicker and smoother start-stop operations, enhance fuel efficiency, and elevate vehicle performance.

Remote and Push-Button Start Technologies

Remote Start: Typically, by using a key fob, this technology allows drivers to start their vehicles from the comfort of their homes or offices. Warm up or cool down the car before the driver gets in is particularly advantageous in extreme weather conditions. In collaboration with the engine control unit (ECU), the body control module (BCM) manages the fundamental operation of this feature. The vehicle authenticates the signal for validity upon detecting the unique signal from the key fob through its Remote Receiver. The BCM transmits a command to the ECU to kick off the engine start sequence once confirmed. The seamless execution of this process guarantees that the vehicle's doors stay locked, ensuring security during remote start operations, all made possible by Door Lock Sensors.

Push-Button Start: The push-button start enables drivers to initiate their vehicles with a simple button press, provided the key fob is within a designated proximity, thus substituting the conventional key ignition system. This feature provides increased convenience and a contemporary user experience for vehicle operators. The engine control unit (ECU) and the body control module (BCM) work together to allow this functionality behind this technology. Continuous scanning for the distinct signal of the key fob is carried out by proximity sensors integrated into the system. The signal’s authenticity is validated by the BCM once the fob is detected within the required range. The BCM communicates with the ECU, initiating the engine’s start sequence once the button is pressed and validated. This interaction guarantees both user-friendly operation and the security of the vehicle, allowing the engine to start solely when the authorized key fob is detected nearby.

Security and Convenience: Advanced security measures are integrated into both systems, preventing the vehicle from being driven unless the key fob is present. Moreover, introducing an additional layer of convenience for users, several of these systems include functionalities such as automatic locking when walking away.

To sum up, to align technological advancements with the requirements of users, the progression in starting systems showcases the automotive industry's endeavor. Making it smoother and more enjoyable for the end-user, these advancements not just enhance vehicle efficiency and performance but also enhance the overall driving experience. We anticipate witnessing further groundbreaking innovations in the domain of vehicle starting systems with the steady advancement of technology.

直接登录

创建新帐号