Importance of BMS in EVs and HEVs

Electric vehicles (Evs) and hybrid electric vehicles (HEVs) depend heavily on battery management systems (BMS). Essentially the brains and heart of these cars, the BMS keeps an eye on the battery pack and regulates it, while also guaranteeing longevity, safety, dependability, and peak performance. The importance of BMS in Evs and HEVs is explored in this section, along with the reasons it is an essential part.

Performance Optimization: A battery management system (BMS) continuously adjusts different battery parameters to make sure the car runs as efficiently and as quickly as possible.

Cost Efficiency: A strong BMS extends battery life, which lowers the frequency and expense of replacements. The overall resale value of the car is positively impacted by its function in protecting the battery.

Sustainability: By means of effective administration, the BMS prolongs the lifespan of batteries, consequently decreasing waste. This feature supports the green goals of EVs and HEVs in an era of environmental consciousness.

Consumer Confidence: Consumer trust is increased when reliable data about the battery's condition and safety is provided. The adoption and acceptability of EVs and HEVs are indirectly influenced by the BMS.

The unsung hero of EVs and HEVs is the battery management system, which does a wide range of tasks to guarantee the vehicle's dependability, safety, and efficiency. The role of a Battery Management System (BMS) is anticipated to become increasingly complex and vital as battery technology advances. The success and sustainability of electric and hybrid vehicles in the future depend heavily on the ongoing development of BMS technologies. The need for engineers and researchers in this field to innovate and adjust to the shifting dynamics of automotive electrification is growing.

Battery Technologies for EVs

Battery systems affect a vehicle’s performance, weight, cost, and charging requirements in addition to determining its range. This section examines the different types of batteries used in Evs and HEVs, highlighting their features and contrasting them through a comparative analysis. Battery technology is an important factor in the development of Evs and HEVs.

Types of Batteries

Lithium-Ion (Li-Ion) Batteries

- Composition: They are made up of lithium compounds as a part of the cathode, along with an electrolyte.

- Characteristics: They are mostly known for high energy density, longer life cycles, and lightweight.

- Applications: They are most common in modern EVs, including Tesla and Nissan Leaf.

Nickel-Metal Hydride (Ni-MH) Batteries

- Composition: They are made up of nickel-hydroxide cathode and a metal hydride anode.

- Characteristics: As compared to Li-ion, they have a lower energy density, but with good life cycles and good thermal performance.

- Applications: They are found in older EV models and some HEVs like the Toyota Prius.

Lead-Acid Batteries

- Composition: They are made of lead electrodes and sulfuric acid electrolytes.

- Characteristics: They are heavier with lower energy density but cost-effective.

- Applications: They are generally used in small-scale applications or as auxiliary batteries.

Solid-State Batteries

- Composition: Instead of liquid or polymer, they use solid electrolytes.

- Characteristics: They have a potential for higher energy density, improved safety, as well as a longer lifespan.

- Applications: Emerging technology; not widely implemented but holds promise for future EVs, however still in the stage of laboratory research rather than mass production.

Comparative Analysis of Battery Technologies

Energy Density

- Li-Ion Batteries: High

- Ni-MH Batteries: Moderate

- Lead-Acid Batteries: Low

- Solid-State Batteries: Highest

Life Cycle

- Li-Ion Batteries: Long

- Ni-MH Batteries: Moderate to Long

- Lead-Acid Batteries: Short

- Solid-State Batteries: Very Long

Cost

- Li-Ion Batteries: Expensive

- Ni-MH Batteries: Moderate

- Lead-Acid Batteries: Cost-Effective

- Solid-State Batteries: Currently Expensive

Safety and Environmental Considerations

- Li-Ion Batteries: There is a general concern over thermal runaway, but improving with advanced BMS.

- Ni-MH Batteries: It is safer and less toxic.

- Lead-Acid Batteries: Environmental concerns due to lead.

- Solid-State Batteries: Expected to be safer, with fewer toxic materials.

Charging Speed and Efficiency

- Li-Ion Batteries: Fast charging capabilities.

- Ni-MH Batteries: Slower than Li-ion.

- Lead-Acid Batteries: Slow and inefficient.

- Solid-State Batteries: Potentially fast, but still under development.

Battery technology for EVs and HEVs is a dynamic and diverse field. Due to their advantageous energy density and long life cycles, lithium-ion batteries currently control a large portion of the market. Nonetheless, every technology possesses a specific role and capacity, contingent upon the demands and limitations inherent in the vehicle's design.

The next big thing in technology is solid-state batteries, which could completely change the way energy storage is used in automobiles. To solve the present issues and open the door to more economical, effective, and sustainable electric mobility options, this field needs to continue its scientific and technological advancements.

EV Specific Considerations in BMS

For electric vehicles (EVs) and hybrid electric vehicles (HEVs) to operate safely and effectively, battery management systems (BMS) are necessary. Battery parameters like voltage, current, temperature, and state of charge are all under the BMS’s supervision and control. The design and implementation of BMS for Evs and HEVs require special considerations, mainly pertaining to the battery pack topologies, as explained below.

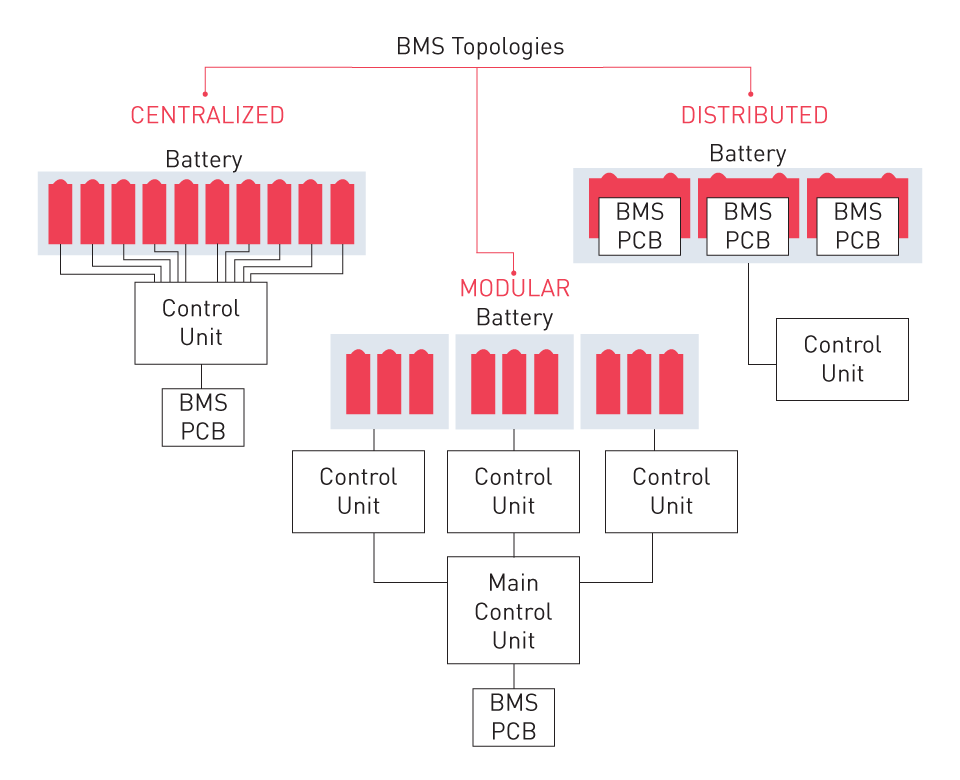

BMS Topologies of EV Battery Packs

Centralized BMS Topology

- Description: The whole battery pack is managed by a single primary controller in a centralized BMS.

- Advantages: Easier to execute, less cost, and simplified design.

- Disadvantages: Single point of failure possibility, restricted scalability.

- Application: Fits small to medium-sized battery packs. Modern cars' lithium low-voltage auxiliary batteries, for instance, employ this architecture.

Distributed BMS Topology

- Description: Each controller in a distributed battery management system (BMS) oversees a different portion of the battery pack.

- Advantages: Localized control, enhanced fault tolerance, and enhanced scalability.

- Disadvantages: Intricacy of coordination and communication among controllers.

- Application: Suitable for sizable, intricate battery packs including several cells or modules.

Modular BMS Topology

- Description: A master controller oversees a group of identical modules that are each in charge of a portion of the battery pack in a modular BMS.

- Advantages: Scalability, design homogeneity, and ease of replacement and maintenance.

- Disadvantages: Moderate complexity and exact coordination between modules are required.

- Application: Fit for battery packs whose dimensions are anticipated to expand or alter.

Figure 1: Different BMS Topologies

Considerations in Selecting BMS Topology

Scalability: Taking into account anticipated expansion or modifications to the dimensions and arrangement of battery packs.

Reliability: To avoid single points of failure, fault tolerance and redundancy are essential.

Performance: maximizing control efficacy, accuracy in monitoring, and response time.

Cost: Juggling the demands for functionality and performance against the financial restrictions.

Maintainability: Component replacement, diagnosis, and maintenance ease.

The BMS topology in EV battery packs is a crucial factor that affects the system's cost, scalability, performance, and dependability.

A wide range of scenarios can be accommodated by advanced BMS designs, which are increasingly important as EV technologies continue to evolve and battery packs become more complex. To guarantee the success and continuous expansion of electric mobility solutions, innovations in this area are crucial.

直接登录

创建新帐号