Introduction to Battery Pack Networking

Specifically in Hybrid Electric Vehicles (HEVs) and Electric Vehicles (EVs), battery pack networking builds a foundation of communication within Battery Management Systems (BMS). In the battery pack, the network guarantees the streamlined, real-time management of individual cells and modules, enabling seamless coordination among charging, discharging, temperature regulation, and health monitoring processes. The technologies of wireless mesh networks and isoSPI communication have become crucial elements in this circumstance.

Introduction to Battery Pack Networking

Between Battery Management System and the individual cells or modules, the network within a battery pack works as the crucial conduit for data flow. It should deliver resilient, noise-resistant communication that enables the BMS to oversee the status of each cell while also ensuring the necessary isolation between battery packs to prevent any potentially dangerous voltage coupling. In this context, two technologies are specifically notable: isoSPI and Wireless Mesh Networks.

isoSPI Communication

isoSPI, short for Isolated Serial Peripheral Interface, serves as a communication protocol specially crafted to facilitate bidirectional communication with galvanic isolation. Let’s have a look at how it works within battery pack networking:

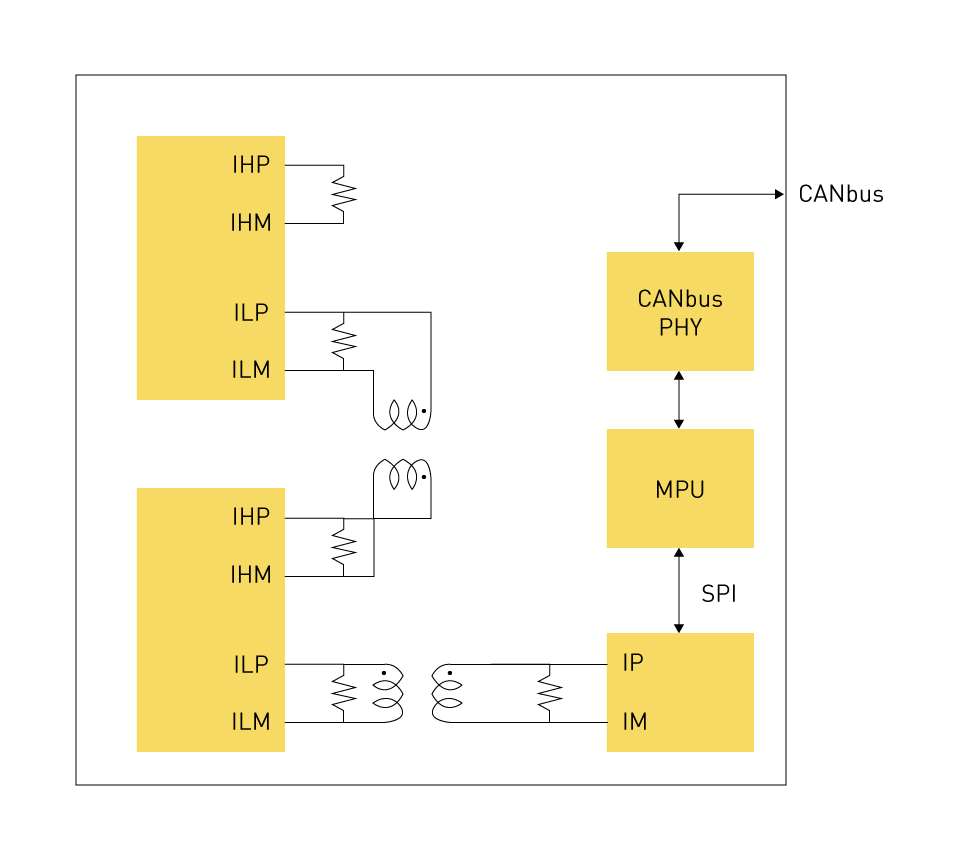

Figure 1: IsoSPI Network

A daisy-chain structure links every node in such a way that each node exclusively communicates with its adjacent neighbors. These neighboring nodes are responsible for ensuring the message's transmission to the master node, which in turn communicates with the host microcontroller. Node isolation is achieved through galvanic means, utilizing either capacitive coupling in standard conditions or isolating transformers in more challenging environments. The IsoSPI bus employs a differential pair configuration.

Noise Immunity: isoSPI significantly lowers noise and the associated potential for communication faults by isolating the ground domains between communicating equipment and using differential pair signals for communication. During communication with high-voltage battery packs, this isolation is critical.

Robustness: The exceptional resilience against transient voltage and current spikes is provided by the isolated interface, rendering it exceptionally dependable in the challenging automotive setting.

Data Integrity: By employing error detection mechanisms, enabling the real-time supervision and management of individual battery cells, isoSPI guarantees data integrity.

Cost-Effectiveness: isoSPI is preferred in automotive applications as it offers strong and isolated communication without significantly rising costs or complications.

Wireless Mesh Networks

In comparison to isoSPIA, a newer tactic to battery pack networking is denoted by wireless mesh networks, which further removes the need for communication wires, featured below:

Flexible Topology: In contrast to old wired networks, wireless mesh networks enable devices to interact in a decentralized and flexible manner. A mesh is formed when every node can communicate with several other nodes. A master node can push the sub-node messages to the host microcontroller.

Scalability: Specifically in large battery packs with many cells, the ability to add or delete nodes without disrupting the network makes network scaling simpler.

Redundancy: The mesh topology enhances reliability by guaranteeing that data can travel along alternate paths in case of one communication path failure.

Potential Challenges: The potential challenges in automotive applications, such as interference with other wireless systems must be overcome by wireless mesh networks while ensuring secure communication and passing the EMI needs.

For the efficient functioning and safety of advanced electric and hybrid vehicles, Battery pack networking plays a pivotal role. IsoSPI technologies offer a resilient and cost-effective means of isolated communication. In contrast, wireless mesh networks provide the required adaptability and scalability for increasingly intricate battery systems, all while eliminating the need for communication wiring, thereby further reducing costs. The key for engineers and technologists working in this continuously changing field is an understanding of these technologies and how they communicate with the complete vehicle architecture. The emergence of these communication paradigms represents a substantial leap forward in battery pack management, indicating a new era of enhanced and intelligent energy storage solutions.

直接登录

创建新帐号