Distribution Transformers

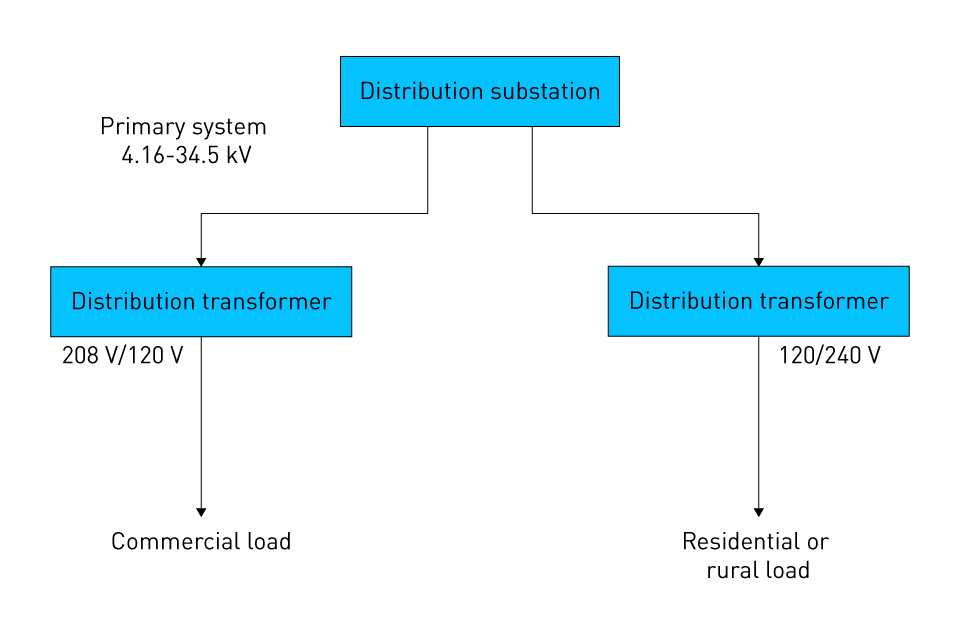

Distribution transformers play a crucial role in electrical power distribution, carrying out the final voltage transformation stage before delivering electrical energy to the end user. The high voltage of the electrical power that is transferred over long distances is reduced by these transformers to lower voltage levels that are suited for usage in commercial, industrial, and residential settings. An examination of the properties, applications, and significance of distribution transformers within the context of the power distribution system is presented in this section.

Figure 8: Role of distribution transformers

Characteristics of Distribution Transformers

In continuous operation, distribution transformers are intended to operate at voltage levels that are typically lower than those used in transmission equipment. This allows them to achieve high levels of efficiency and dependability. They are distinguished by their relatively tiny size and power rating, and they are intended to provide service to individual consumers, communities, or small industrial operations. Depending on the requirements of the distribution network and the end users, the usual output voltage can range anywhere from a few hundred volts to approximately 35 kilovolts.

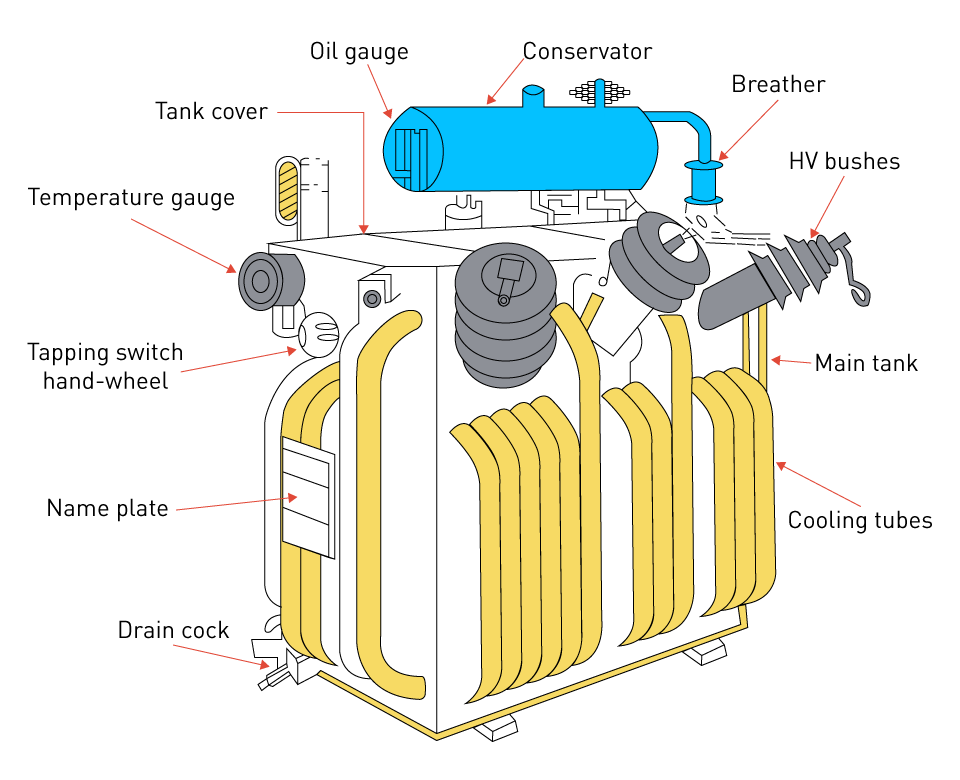

Figure 9: Oil immersed natural cooled distribution transformer

Distribution transformers are characterized by their great efficiency, which frequently exceeds 95%. This is of utmost importance because of the constant operation of these transformers. Even little enhancements in efficiency can result in huge savings in terms of both energy and money over the course of time. However, regardless of whether they are mounted on utility poles, housed in underground vaults, or set on ground pads, they are constructed to be able to endure the environmental conditions that are present at the locations where they are installed.

Applications of Distribution Transformers

The most important function of distribution transformers is to reduce the voltage carried by the distribution lines to a level that is suitable for use in residential and commercial buildings, as well as small industrial plants. When it comes to supplying consumers with power, they are omnipresent in both urban and rural areas, where they do so in a quiet and dependable manner. Distribution transformers, in addition to transforming voltage, also offer electrical isolation between the high-voltage distribution network and consumers. This isolation has the dual purpose of boosting safety and protecting against electrical problems.

Pole-Mounted vs. Pad-Mounted Distribution Transformers

Broadly speaking, distribution transformers fall into two primary categories: pole-mounted and pad-mounted.

Pole-Mounted Transformers: Rural or suburban regions with a high prevalence of overhead distribution lines for power distribution frequently use transformers mounted on poles. Utility poles have affixed them at a height that prevents accidental contact between them. Pole-mounted transformers typically cater to a limited number of clients, like a single residence or a small group of buildings.

Pad-Mounted Transformers: To ensure safety, pad-mounted transformers are installed on concrete pads at ground level and encased in secured metal cabinets. Urban areas and residential subdivisions with underground electricity delivery typically feature pad-mounted transformers. They are designed to be more aesthetically beautiful and less intrusive than pole-mounted units, and they are able to serve a greater number of clients or commercial and industrial buildings.

Power Transformers

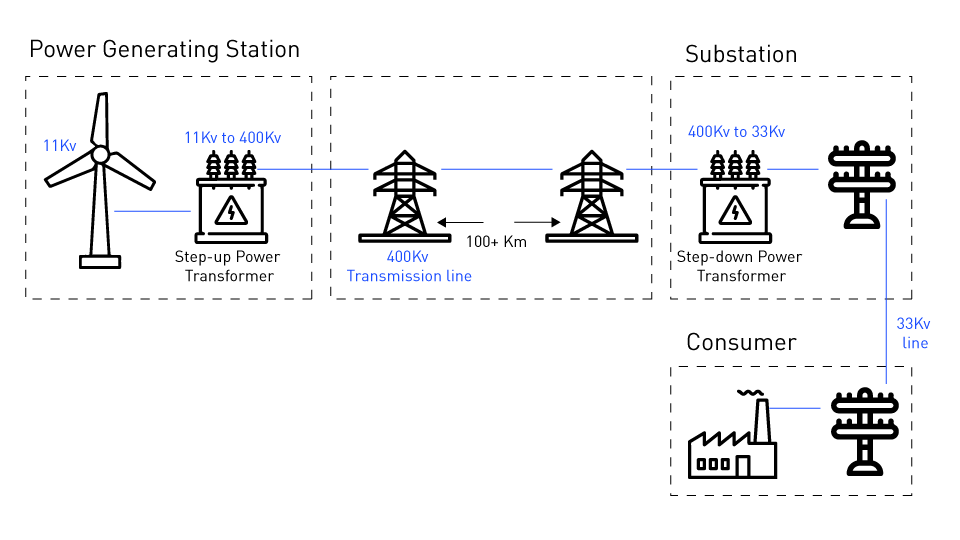

Power transformers are essential components that comprise the electrical power generation, transmission, and distribution system. These transformers are intended to manage high voltages and enormous loads over extended distances. They play a crucial part in the processes of step-up and step-down voltage levels that occur between the power plant and the distribution network. This aids in the efficient transfer of electrical energy over extensive geographic regions. In this section, we will look into the properties, applications, and relevance of power transformers within the larger framework of power systems.

Figure 10: Power transformer

Characteristics of Power Transformers

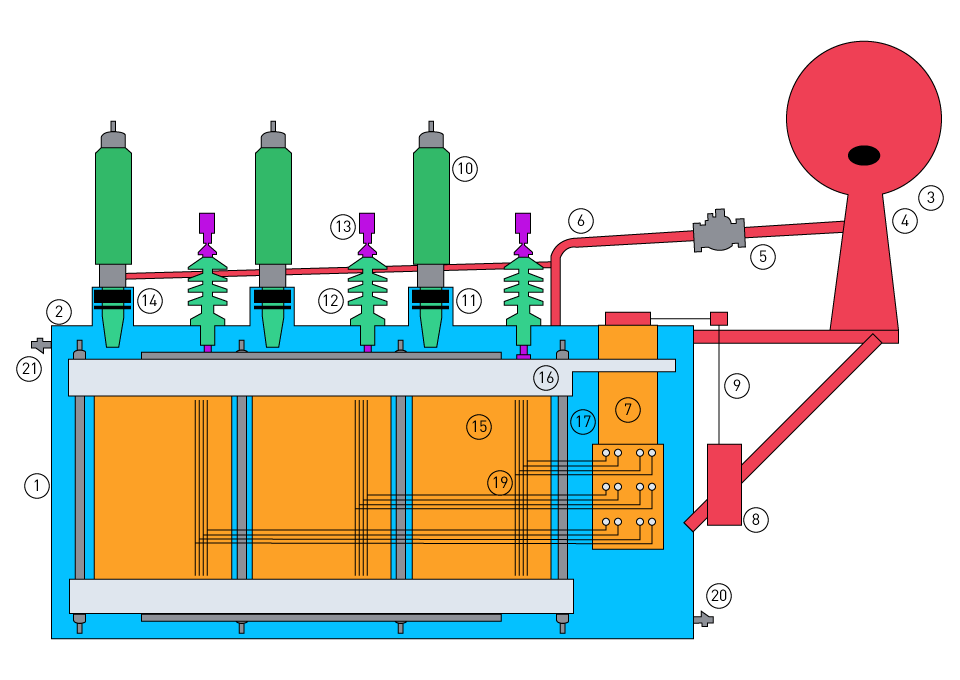

The capacity of power transformers can range from several hundred megavolt-amperes (MVA) and often exceed 200 kilovolts (kV). High power ratings and their ability to function at high voltages distinguish power transformers. These transformers strive for maximum efficiency, typically exceeding 99%, to minimize losses during energy transmission. Given their significant role in the power grid, their construction prioritizes stability and dependability, enabling them to endure the harsh conditions of high voltage operations.

Figure 11: Power transformer schematic

Substations typically install power transformers due to their size and exposure to high voltages. This is because substations are better equipped to provide necessary maintenance and monitoring. Oil or gas insulation is commonly used to offer cooling and additional electrical insulation. Their construction and insulation systems are carefully built to handle the severe electrical stresses that they are subjected to.

Applications of Power Transformers

One of the most important applications for power transformers is in the transmission network of the power system, where they provide two basic functions:

Voltage Step-Up: Power transformers on the generation side raise the voltage of the generated power to increased levels, causing a step-up in voltage. As a result of this step-up process, the current is decreased for a given power level, which in turn minimizes the resistive losses that occur in the transmission lines that are located at great distances from the load centers.

Voltage Step-Down: Power transformers, which are located closer to the places of consumption, either within sub-transmission or main distribution substations, reduce the voltage from high transmission levels to lower levels that are suitable for distribution networks. When it comes to securely supplying power to end-users and distribution transformers, this step-down procedure is absolutely necessary. Distribution transformers further reduce the voltage for use in residential, commercial, or industrial settings.

Significance of Power Transformers

The effectiveness and dependability of the electrical grid are directly correlated to the presence of power transformers. They make it possible to transmit electrical power across enormous distances, which is an essential component of contemporary electrical distribution networks. This enables the generation of power in a centralized manner, which might include the generation of power from renewable sources. Power transformers play a significant role in minimizing transmission losses, improving grid stability, and ensuring that electricity is delivered to end-users in the most efficient manner possible. They do this by optimizing the voltage levels for transmission and distribution.

In addition, because of their capacity to manage enormous power flows, they are vital in the process of interconnecting grids in different regions. This makes it possible to interchange power and provide backup, which in turn improves the overall dependability and resilience of the power system in the face of power outages and peak demand.

Autotransformers

Autotransformers are a sort of transformer that is both distinctive and effective. Although they share some operational principles with conventional transformers, autotransformers are also fundamentally different in terms of their design and their applications. This layout connects both the primary and secondary circuits to a single winding, sharing a portion of the winding between both circuits. In this part, the design, operation, and uses of autotransformers are discussed. Particular attention is paid to the benefits of autotransformers and the specific applications they have inside electrical systems.

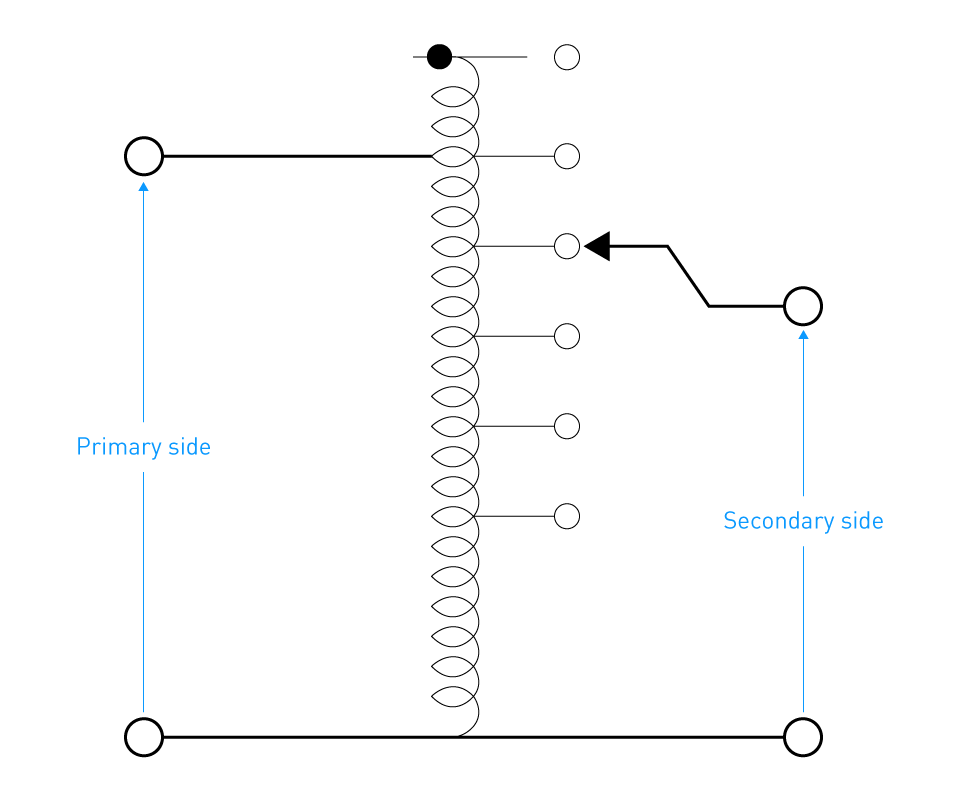

Figure 12: Autotransformer

Design and Operation

An autotransformer is a type of transformer that uses a single, continuous winding with taps located at various positions along the winding to produce different voltage levels. This is in contrast to a traditional transformer, which has one primary winding and two secondary windings independently. The section of the winding, also known as the common section, carries the current that both the input and the output share. The remaining section of the winding is responsible for carrying the difference in current that exists between the primary and secondary sides.

Furthermore, the primary and secondary circuits share a winding terminal that is common to both of them. An additional terminal for the primary circuit is provided by a tap in the winding, and the other terminal for the secondary circuit is provided by another tap. Depending on the taps that are selected, this arrangement makes it possible to have a transformation ratio that is flexible. This configuration also makes it possible for the autotransformer to regulate voltage levels in an effective manner.

Applications

In many different applications, autotransformers are utilized in situations where there is a need for voltage variation but where isolation between primary and secondary circuits is not of the utmost importance. These are some examples of common applications:

Voltage Regulation: Autotransformers can be utilized for the purpose of making tiny modifications to voltage levels. This includes adjusting for voltage loss over longer distribution lines or in industrial applications where certain voltage levels are required for the operation of equipment.

Railway Systems: Automobile transformers are utilized by a significant number of electric railway systems in order to deliver power to the trains. Autotransformers are ideally suited for this application because of their capacity to make effective adjustments to voltage levels. This application involves lengthy distances and can result in a substantial voltage drop.

Starter Motors: Autotransformers are occasionally used to start big induction motors. They provide a decreased voltage during initiation, which helps to reduce inrush current and minimize mechanical stress on the motor as well as electrical stress on the power supply system. Starter motors are sometimes known as starter motors.

Interconnecting Systems: Autotransformers offer an effective method of connecting power systems that require connections of multiple voltage levels but do not require direct electrical isolation. This type of interconnection is necessary in power systems.

Advantages

Efficiency: In applications that do not require complete isolation between the primary and secondary circuits, autotransformers are typically more efficient than traditional transformers. This is because autotransformers are designed to replace conventional transformers. The common winding portion reduces the amount of copper used, thereby reducing resistive losses.

Cost-Effectiveness: Autotransformers are a cost-effective alternative for a wide variety of applications since they require a smaller quantity of winding material than other types of transformers.

Compact Size: Autotransformers are able to be more compact and lighter than conventional transformers because they have fewer windings than conventional transformers. This is helpful in applications that have limited space.

Three-Phase Transformers

When it comes to the distribution and consumption of electrical power in residential, commercial, and industrial situations where three-phase electricity is necessary, three-phase transformers are an essential component. In contrast to a single-phase transformer, which is only capable of handling a single phase of electricity through the use of two wires, a three-phase transformer can handle three phases simultaneously through the use of either three independent coils (one for each phase) or a single three-phase core. This section delves into the structure, function, and benefits of three-phase transformers, highlighting their utility in alternating current (AC) power systems.

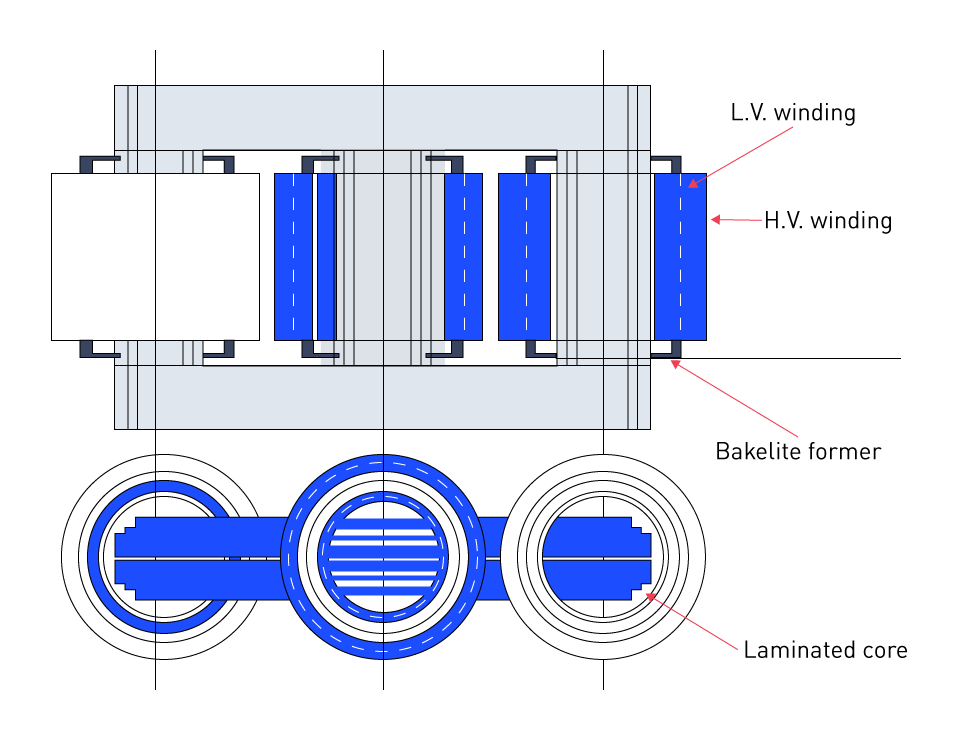

Figure 13: Three phase core type transformer

Structure and Operation

Two basic methods are available for the construction of three-phase transformers: the first method involves combining three single-phase transformers to create a three-phase bank, and the second method involves utilizing a single unit that contains a three-phase core. When compared to a comparable set-up consisting of three single-phase units, the three-phase core design is more compact and cost-effective. It also provides higher power consistency and lower material requirements.

Three-phase transformers operate on the same principle of electromagnetic induction as single-phase transformers. Conversely, their purpose is to regulate three phases of alternating current (AC) power, rendering them a superior option for systems that prioritize power density and efficiency. The configurations in which three-phase transformers can be linked can vary, depending on the requirements of the application in terms of voltage levels and phase stability. These configurations include star (Y) connections, delta (<0xD3>) connections, or a combination of both variations.

Applications

The transmission and distribution of electrical power across large areas, as well as in industrial applications that require high power levels, are two of the most common applications for three-phase transformers. Three-phase transformers find their applications in the following fields, among others:

Power Transmission and Distribution: The transmission and distribution of power entails stepping down the high-voltage electricity that is transmitted through transmission lines to lower voltages that are acceptable for use in commercial and industrial settings, as well as further distribution to residential areas.

Industrial Applications: Applications in Industry Industrial motors, drives, and other equipment that require three-phase power use three-phase transformers to achieve the highest levels of efficiency and performance.

Commercial Buildings: In commercial environments, such as office buildings and retail centers, three-phase transformers distribute electricity for lighting, heating, ventilation, and air conditioning (HVAC) systems, and office equipment. This allows for more effective load balancing than single-phase power.

Advantages

There are a number of advantages that come with the utilization of three-phase transformers in power systems:

Efficiency: Single-phase transformers are less efficient than three-phase transformers when it comes to transferring and distributing power over long distances. This is because three-phase transformers are more efficient than single-phase transformers.

Compact Design: The compact design of a single three-phase transformer takes up less space and requires fewer materials than three separate single-phase transformers, which contributes to cost savings in terms of both materials and installation.

Improved Power Quality: Three-phase transformers offer a balanced power supply, which lessens the likelihood of phase imbalances and improves the overall power quality that is given to end-users.

Versatility: Three-phase transformers offer greater flexibility in power system design due to their versatility, which is achieved through the availability of a variety of connection configurations. These configurations allow the transformers to be altered to meet the specific voltage and phase needs of diverse applications.

直接登录

创建新帐号