Tap-Changing Transformers

Tap-changing transformers play a crucial role in voltage regulation, ensuring that voltage levels remain optimal even when there are changes in load conditions within power distribution networks. By adjusting the voltage ratios, these transformers may respond to variations in the power load without disrupting service continuity.

Functionality of Tap-Changing Transformers

In order to modify the output voltage to a desired level, tap-changing transformers use a mechanism that can alter the tapping point of the transformer on the windings. This modification ensures that the voltage supplied to end users stays within the designated limits by adjusting for voltage rises or drops in the power distribution network.

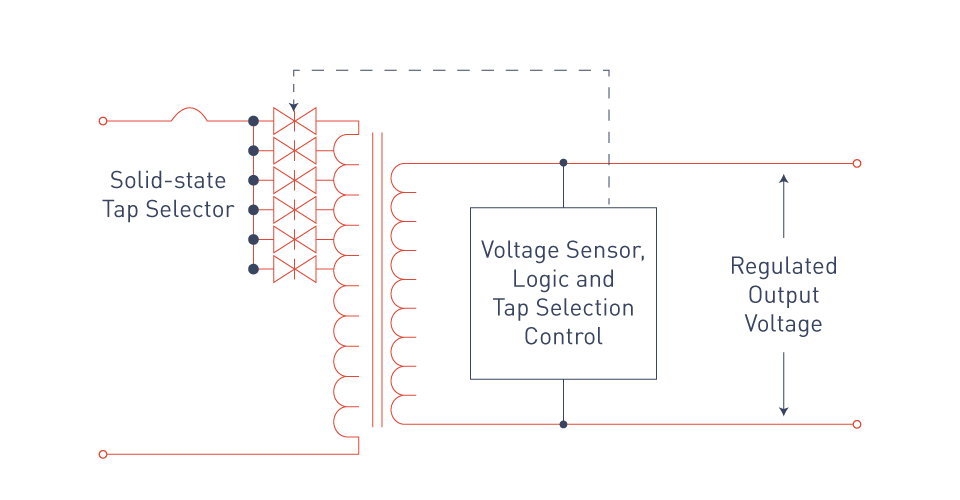

Figure 4: tap-changing voltage regulator

Types of Tap Changers:

- On-Load Tap Changers (OLTC): These gadgets have the ability to modify the taps on a transformer when it is both activated and under load. This feature is essential for dynamic and continuous voltage management in reaction to real-time variations in load demand.

- Off-Load Tap Changers: To change the tap on these, the transformer must be de-energized. They are employed in situations where it is appropriate to cut power to make adjustments, usually in regions with less fluctuating demand.

Applications of Tap-Changing Transformers

Grid Stability and Efficiency: Tap-changing transformers, particularly in systems with highly fluctuating load patterns, are essential for stabilizing the electrical grid by dynamically modifying the voltage levels.

Enhanced Power Quality: By keeping the voltage level steady, you may lessen the load on your infrastructure and electrical devices, which improves power quality overall and lowers the likelihood that sensitive equipment will experience voltage-related problems.

Load Management: Tap-changing transformers enable efficient load control in industrial and big commercial environments, enhancing the effectiveness and efficiency of the power supply system.

Advantages of Tap-Changing Transformers

Flexibility: In complicated and dynamic power systems, tap changers are especially useful because they offer the flexibility required to control voltage levels under a variety of circumstances.

Reliability: Even in the face of varying load conditions, power quality is maintained because of OLTCs' capacity to switch taps while under load.

Cost-Efficiency: These transformers save energy and lower operating costs by optimizing voltage levels, which helps to minimize energy losses from excessive voltage drops or rises.

Considerations and Challenges

Maintenance Requirements: Because of their mechanical complexity and the physical wear associated with changing taps, tap-changing transformers, especially OLTCs, need to have frequent maintenance performed to guarantee dependable operation.

Investment Cost: Despite their many advantages, tap-changing transformers require a larger initial investment than fixed-ratio transformers. The long-term savings must be weighed against the initial expenses when deciding whether to implement them.

Solid-State Voltage Regulators

Solid-state voltage regulators are an advanced category of voltage regulation technologies that use semiconductor devices to adjust voltage levels quickly, effectively, and dependably in a variety of applications. These regulators, in contrast to mechanical devices, employ electronic components instead of actual moving parts to smoothly control voltage output.

Functionality of Solid-State Voltage Regulators

Semiconductors like thyristors, transistors, and diodes are used by solid-state voltage regulators to regulate the voltage output. In order to maintain a consistent output voltage regardless of variations in load or input voltage, these components vary the duty cycle in DC applications or adjust the phase angle of the incoming AC power.

Types of Solid-State Regulators:

- Linear Voltage Regulators: These regulators work by generating a steady output by dissipating excess voltage as heat via a resistive voltage drop. They are well-known for being straightforward and having incredibly low output noise, which makes them appropriate for delicate electronic equipment.

- Switching Regulators: By using high-frequency switching and energy-storage components like inductors and capacitors, switching regulators are more effective than linear regulators at converting the input voltage to a higher or lower output voltage. Because of their effectiveness and versatility in step-up and step-down applications, they are utilized extensively.

Applications of Solid-State Voltage Regulators

Industrial Systems: Precise voltage control is required to preserve the quality and uniformity of production processes, and these regulators are essential in automated manufacturing environments.

Renewable Energy Systems: To provide consistent power output for inverters, battery storage systems, and the grid, regulate the voltage from solar panels and wind turbines.

Telecommunications: To guarantee continuous and dependable signal transmission, control voltages in communication towers and base stations.

Advantages of Solid-State Voltage Regulators

High Efficiency and Reliability: Solid-state regulators have a low loss rate when managing power, and the absence of mechanical elements in them lessens wear and the chance of a mechanical failure.

Fast Response Times: Even in dynamic situations, these devices may provide a reliable power supply by responding virtually instantly to changes in load or input voltage.

Compact and Lightweight: Solid-state regulators are smaller and lighter since they do not have big mechanical components, which is important in areas with limited space and for mobile applications.

Considerations and Challenges

Heat Management: Solid-state devices, although efficient, can produce a lot of heat when operating at higher currents or voltages. Therefore, strong heat dissipation systems are necessary to avoid damage or performance degradation.

Complexity and Cost: Compared to conventional mechanical regulators, the design and implementation of solid-state voltage regulators can be more complicated and expensive, especially for high-power applications.

Automatic Voltage Stabilizers

Automatic voltage stabilizers, which are built to automatically maintain constant voltage levels despite variations in the input supply, are crucial parts of power conditioning systems. These devices are essential for shielding delicate electronic equipment from the damaging effects of voltage fluctuations, which can result in hardware damage, data loss, or operational inefficiency.

Functionality of Automatic Voltage Stabilizers

Automatic voltage stabilizers use a mix of transformers, sensors, and control circuits to bring the voltage down to a level that is safe and steady. To provide a steady and consistent supply, these stabilizers dynamically modify the output in response to variations in the input voltage.

Working Principle: The majority of automatic voltage stabilizers use electronic circuitry or servo-controlled electromechanical devices. A motor modifies the transformer taps in servo-controlled stabilizers in response to the input voltage. In solid-state models, the process of adjusting voltage is managed by electronic circuitry, which frequently uses methods like pulse-width modulation (PWM) to provide precise voltage regulation.

Components: Autotransformers, servo motors (in electromechanical stabilizers), comparators, control circuits, and occasionally microcontrollers for more exact control in more sophisticated models are important parts.

Applications of Automatic Voltage Stabilizers

Home Appliances: To guard against low or excessive voltage levels that could result in damage or inefficiency for equipment including air conditioners, refrigerators, and televisions.

Office Equipment: Stabilizers in office settings make sure that devices like printers, scanners, and PCs run under ideal electrical conditions, extending their lifespan and preventing malfunctions.

Industrial Machinery: Voltage stabilizers are essential in industrial settings for devices like CNC machines and assembly line robotics that depend on a steady voltage for precise and secure functioning.

Advantages of Automatic Voltage Stabilizers

Enhanced Equipment Protection: These stabilizers shield delicate electronics from voltage spikes, sags, and other irregularities that may result in immediate or cumulative damage by supplying a steady voltage.

Improved Power Efficiency: Stable voltage reduces the energy consumption of electrical devices by preventing them from drawing as much current as they otherwise would in order to function in conditions of fluctuating voltage.

Reduced Downtime and Maintenance Costs: Stable voltage reduces the likelihood of equipment failures and interruptions, which lowers maintenance expenses and downtime.

Considerations and Challenges

Size and Cost: Larger automated voltage stabilizers can be costly and large, but they are essential for high-power applications. A trade-off between size, cost, and the particular requirements of the application is frequently present when selecting between several stabilizer kinds.

Response Time: Electromechanical stabilizers may react more slowly than modern solid-state stabilizers, which could be a drawback in situations involving frequent and rapid voltage swings.

Wear and Tear in Mechanical Models: Because electromechanical stabilizers have moving parts, they are susceptible to wear and tear over time and need constant upkeep.

直接登录

创建新帐号