Voltage Regulators

Voltage regulators are essential components in power conditioning systems. Their purpose is to maintain a constant voltage level for electrical devices, despite fluctuations in the system's consumed voltage. This section discusses two principal forms of voltage regulators: Automatic Voltage Regulators (AVRs) and Ferroresonant Transformers. Each of these types of voltage regulators serves a different purpose within power delivery systems.

Automatic Voltage Regulators (AVRs)

Automatic Voltage Regulators, more frequently referred to as AVRs, are electrical devices that automatically regulate the voltage to a predetermined level. This ensures that all of the connected equipment receives electricity that is steady and consistent. Automatic voltage regulators (AVRs) are a vital component in situations where the power supply voltages fluctuate dramatically, which can be damaging to sensitive electronic equipment.

Functionality: AVRs are able to do a speedy comparison of the incoming power voltage to a reference voltage that has been predetermined. If there is a difference, the AVR will automatically change the output voltage to either increase or decrease such that it is in line with the reference level. During this procedure, electronic sensors and microprocessor controllers are utilized. These controllers are responsible for regulating the voltage by switching electronic circuits or mechanically adjusting taps on a power transformer.

Applications: Advanced voltage regulators (AVRs) find widespread application in the fields of information technology (IT), telecommunications, and industrial applications. These are all areas where accurate voltage management is essential for the protection of sensitive equipment and the smooth running of operations.

Ferroresonant Transformers

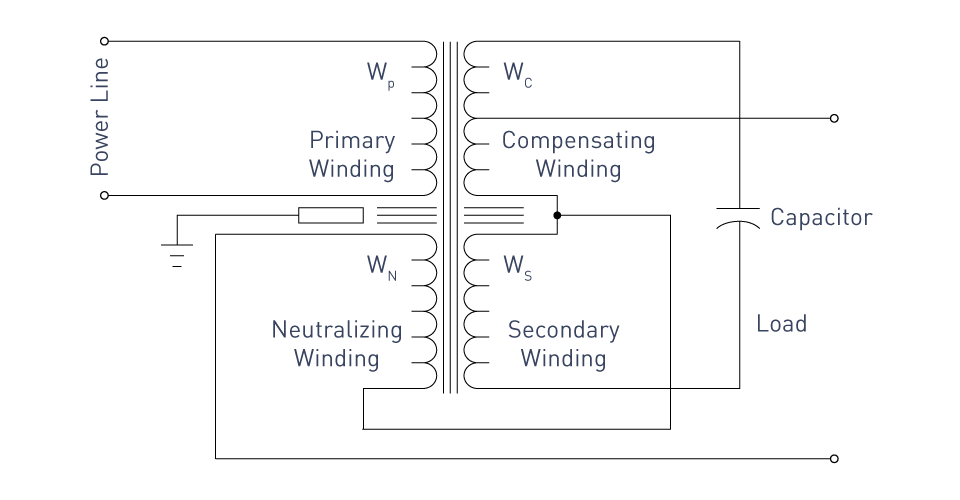

Often known as constant voltage transformers (CVTs), ferroresonant transformers reliably regulate voltage through a tank circuit consisting of a capacitor and a high-voltage resonant winding. Ferroresonant transformers, in contrast to alternating current transformers (AVRs), have the ability to store energy inherently, which enables them to provide superior protection against transient power disruptions.

Through the process of changing the magnetic flux within the core of the transformer, compensating windings in these transformers contribute to the maintenance of a consistent output voltage.

Neutralizing windings are auxiliary windings designed to mitigate undesirable effects like harmonic distortions and voltage imbalances.

Figure 2: Ferroresonant transformer with compensating and neutralizing windings

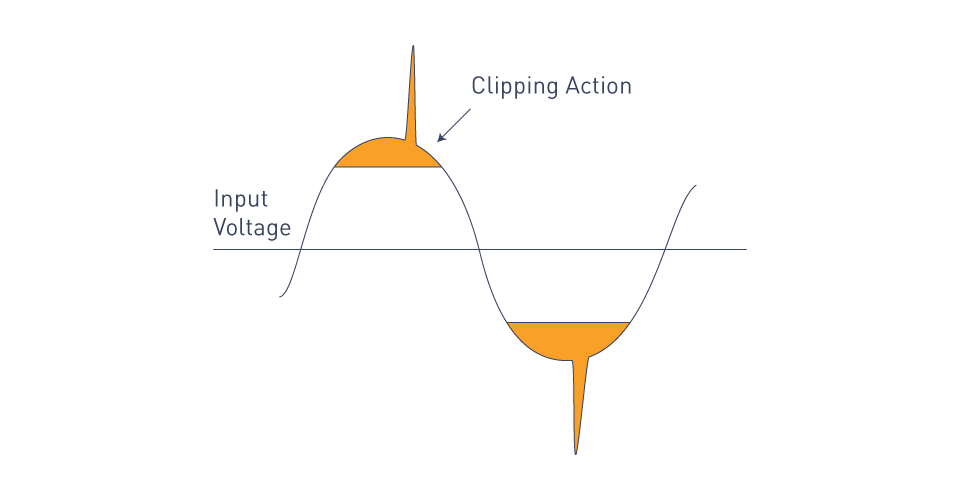

Functionality: The ferroresonant technique makes use of the saturation capabilities of the iron core of the transformer as well as the resonating action of the capacitors. This combination makes it possible for the device to have a reasonably constant output voltage despite large variations in the voltage that is being supplied, provided that the input voltage stays within a certain range. The ability of this device to regulate causes transients and noise bursts to be clipped, which is harmful to the system.

Figure 3: Clipping characteristics of a ferroresonant transformer

Advantages: Ferroresonant transformers have the capacity to provide intrinsic noise filtering and short-term power ride-through capabilities, which makes them very helpful in industrial environments where machines may generate large electrical noise and disturbances. This is one of the most important advantages of ferroresonant transformers.

Limitations: Ferroresonant transformers have a number of limitations, the most significant of which being their size, weight, and perhaps inferior energy efficiency when compared to electronic alternating current transformers (AVRs). They produce more heat and may be noisier than electronic ones.

Power Conditioners

In order to improve the quality of the power that is supplied to electrical equipment, power conditioners play a crucial function. This helps to ensure that the equipment operates at its best and has a longer lifespan. There are two basic types of power conditioners: active power conditioners and passive power conditioners. Each of these types of power conditioners is designed to handle unique power quality challenges in a variety of situations.

Active Power Conditioners

Active Power Conditioners, often known as APCs, are highly advanced devices that dynamically rectify a variety of power quality issues in real time. These issues include voltage sags, swells, harmonic distortions, and fluctuations. The adaptability of these devices is exceptional, and they are able to react instantly to any changes that occur in the electrical environment.

Functionality: APCs are able to perform their functions by continuously monitoring the power line and utilizing power electronic circuits to generate compensatory currents in order to stabilize the power line and stabilize disturbances. Injecting these currents into the power line neutralizes undesirable components like harmonics and reactive power, ultimately stabilizing the power supply.

Applications: The usage of active power conditioners is especially beneficial in industrial settings, which are characterized by the presence of heavy machinery and variable frequency motors, both of which generate complicated power disturbances. The use of these devices is also advantageous in data centers and medical facilities, both of which are places where even very slight power quality issues can result in severe disruptions to operations.

Advantages: In terms of advantages, the capacity of APCs to perform comprehensive power quality adjustment is the most significant advantage they offer. Active conditioners are able to respond to a wide variety of problems and provide tailored adjustments, in contrast to passive systems, which are restricted to particular frequencies or types of disturbances. ‘

Passive Power Conditioners

To increase the power quality, passive power conditioners (PPCs) use a combination of inductors, capacitors, and resistors. This allows them to filter out noise and reduce harmonics, improving the power quality. However, despite their relatively lower level of complexity in comparison to their active counterparts, these devices are extremely successful at addressing specific and predictable power quality issues.

Functionality: Passive conditioners are able to function without the requirement for electrical controls that are particularly complicated. Low-pass or band-pass filters are meant to be created by them. These filters are designed to selectively reduce or eliminate frequencies that are not desired from the power supply.

Applications: Passive power conditioners are frequently utilized in residential and commercial settings where power quality issues are rather consistent and predictable. For example, they are utilized in audio/video setups to eliminate interference that can lead to a decrease in performance.

Advantages: Compared to active conditioners, passive power conditioners (PPCs) are typically more cost-effective and long-lasting due to the absence of active electronic components in their construction. In addition to requiring little to no maintenance, they offer dependable service over an extended period of time.

Surge Suppressors and Voltage Stabilizers

Surge suppressors and voltage stabilizers are two of the most important components that make up the suite of power conditioning systems. These components were developed with the express purpose of improving the safety and reliability of electrical systems. These devices play a crucial role in minimizing damage caused by power surges and maintaining regular voltage levels. As a result, they ensure the safety of connected equipment and ensure that it will last for a long time.

Surge Suppressors

Surge suppressors (or surge protectors), shield electrical equipment from voltage spikes. It is possible for these spikes to occur for a variety of reasons, such as lightning strikes, power outages, or major changes in the amount of electricity that is being used.

Functionality: Surge suppressors are able to deliver their functionality by identifying instances of excessive voltage and directing the excess energy away from the equipment that is being safeguarded by means of a grounding wire. In a surge suppressor, the most important component is a metal oxide varistor (MOV), which is a device that alters its resistance in response to fluctuations in voltage. This allows the surge suppressor to divert the excess voltage away from the components that are sensitive to it.

Applications: Surge suppressors have widespread application in a variety of configurations, including residential, commercial, and industrial contexts. They play an essential role in protecting electronic devices such as computers, communication systems, home appliances, and any other technology that is susceptible to damage from abrupt voltage spikes.

Advantages: The ability of surge suppressors to avoid expensive and severe damage to electrical equipment is the principal advantage of using these devices. They offer instant protection against transient voltage spikes, are generally affordable, and are simple to install. Their installation is also simple.

Voltage Stabilizers

Voltage stabilizers are utilized to provide a consistent voltage level to electrical devices. They do this by adjusting for variations in the input voltage, which can lead to inefficient functioning or even damage.

Functionality: Voltage stabilizers adjust the voltage to a safe range before it reaches the linked equipment. This is how voltage stabilizers function. It is possible for them to be electromechanical or electronic, with the latter offering a voltage adjustment technique that is both more rapid and accurate. The stabilizer detects fluctuations in the power supply and automatically adjusts to maintain a constant output voltage.

Applications: When it comes to applications, voltage stabilizers are absolutely necessary in regions where the power supply is subject to frequent variations. It is standard practice to use them in conjunction with air conditioners, refrigeration units, televisions, and other home equipment that require a consistent voltage in order to function safely.

Advantages: Voltage stabilizers have a number of benefits, including the ability to lengthen the lifespan of electrical devices, lower the costs of maintenance, and improve energy efficiency. They achieve this by providing a constant output voltage. In addition to this, they prevent the loss of data in digital equipment and limit the likelihood of disruptions to operational processes.

直接登录

创建新帐号