Power Quality Parameters

For the purpose of building, operating, and maintaining electrical systems that are dependable and efficient, it is critical to have a solid understanding of the characteristics that characterize power quality. Voltage regulation, frequency stability, and harmonic distortion are the three basic factors that play significant roles in the overall power quality that electrical equipment is exposed to.

Voltage Regulation

A power system is said to have the capability of maintaining a constant voltage level despite changes in load conditions or input voltage. This ability is referred to as being able to regulate voltage. Because severe variances can result in equipment malfunction, decreased efficiency, or even damage, proper voltage regulation is considered to be of the utmost importance.

Importance: It is important to note that voltage levels that are too high can cause an excessive amount of current to flow through electrical components, which can result in overheating and a reduction in the lifespan of the components. At the other end of the spectrum, voltages that are too low may not provide sufficient power to devices, which can result in decreased performance and increased wear.

Measurement and Control: Voltage regulation is usually done with voltage regulators, transformers that can switch taps, and modern power electronic devices like static VAR compensators that change the impedances in the power system.

Frequency Stability

The term "frequency stability" refers to maintaining the frequency of the power system within tight constraints around a defined nominal value (usually 50 Hz or 60 Hz, depending on the location). Maintaining stability is vital for the operation of synchronous machines and other frequency-sensitive equipment, as it is possible for frequency changes to arise as a result of imbalances between load and generation.

Importance: Frequency variations can result in inappropriate operation of electrical equipment, decreased efficiency, and, in extreme circumstances, the disconnection of generators and blackouts. Understanding the significance of this phenomenon is essential.

Management Techniques: As part of management techniques, frequency is managed by altering the equilibrium between the amount of power generated and the amount of load. In power plants, automatic generation control (AGC) systems are responsible for adjusting the output of generators to suit the load and ensuring that the frequency of the system remains within the set limits.

Harmonic Distortion

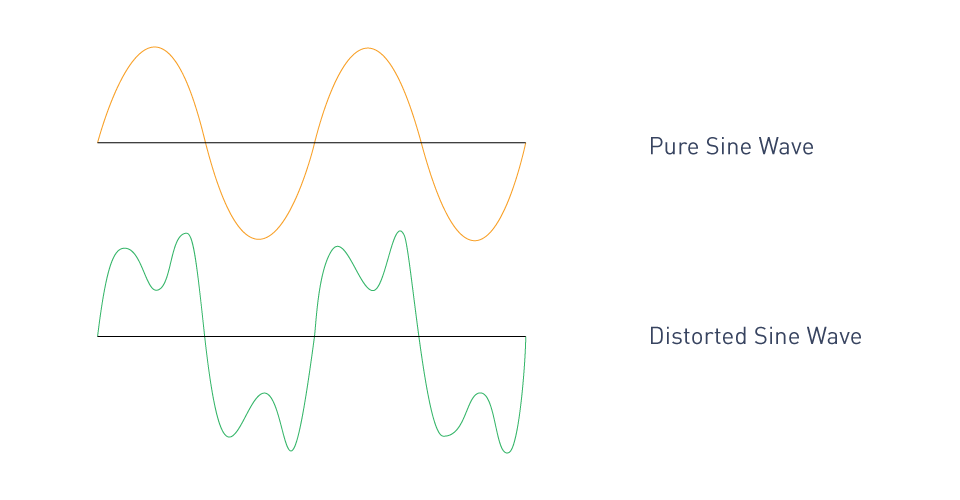

A divergence from the ideal sinusoidal waveform of electrical power is known as harmonic distortion. This deviation is characterized by the existence of frequencies that are multiples of the fundamental frequency. Electronic drives, computers, and lighting systems that are designed to save energy are examples of non-linear loads that are often responsible for the generation of harmonics.

Figure 1: Effect of harmonic distortion

Importance: The significance of this information lies in the fact that high levels of harmonic distortion can result in the overheating of electrical cables and transformers, interfere with communication lines, and cause sensitive electronic equipment to cease functioning properly.

Mitigation Strategies: The use of harmonic filters, the designing of electrical networks to reduce resonances, and the use of advanced power electronic converters that are able to actively adjust for harmonics are all strategies that engineers employ in order to control harmonic distortion.

Impact of Poor Power Quality on Electrical Equipment

Inadequate power quality can have serious negative consequences on electrical equipment, which can result in decreased efficiency, increased operational expenses, and early breakdown of the equipment. It is vital to have a thorough understanding of the impact that poor power quality has in order to effectively adopt steps to protect sensitive equipment and guarantee the performance of the system.

Direct Impacts on Electrical Equipment

Reduced Efficiency and Performance: Voltage and frequency fluctuations can lead to inefficient operation of electric motors and other machinery. It is possible for low voltage to result in a larger current draw in order to keep the same power output. This can lead to an increase in losses owing to heat and a decrease in the overall efficiency of the equipment.

Overheating: The development of additional heat within power systems is often the result of harmonic disturbances, which can lead to extreme temperatures. The excessive heat can put a strain on electrical components such as transformers, capacitors, and cables, which can not only shorten the lifespan of these components but also increase the likelihood that they will catch fire.

Operational Disruptions: The sudden sags or swells in voltage, as well as transient spikes, have the potential to cause operational disruptions. These types of disruptions can affect sensitive equipment, such as computers and Programmable Logic Controllers (PLCs). These disturbances frequently result in the loss of data, the need to reset the system, and, in extreme circumstances, the entire cessation of operations.

Mechanical Stress: The mechanical stress that occurs in electrical equipment, particularly spinning machinery, is caused by the fact that it is designed to function within a given frequency range. The action of a motor can become asynchronous when there are changes in frequency, which can result in higher mechanical stresses and eventually wear and tear.

Damage and Premature Aging: Electrical components can be irreversibly damaged if they are subjected to poor power quality circumstances over an extended period of time. These conditions include low voltage, excessive voltage, or distorted waveforms. For example, capacitors may deteriorate more quickly when subjected to harmonic stress, and insulation on wiring may become damaged when subjected to conditions of persistent overvoltage on a regular basis.

Indirect Impacts on System Reliability

System Instability: Voltage instability throughout the network can be caused by poor power quality, which can lead to an increase in reactive power in the system. This, in turn, limits the capacity of transmission lines and can cause voltage instability throughout the network.

Increased Maintenance and Operational Costs: Equipment that is impacted by poor power quality requires more frequent repairs and maintenance, which can lead to a large increase in operational expenses and a higher amount of downtime.

Mitigation Strategies

A variety of approaches can be utilized in order to lessen the severity of these effects:

Power Conditioning Equipment: The installation of devices such as voltage regulators, uninterruptible power supply (UPS) systems, and harmonic filters can assist in maintaining power quality within certain acceptable parameters.

Proper System Design: Proper system design refers to the process of designing electrical systems with sufficient tolerance for power quality concerns, including the selection of components that can deal with infrequent disturbances.

Regular Monitoring and Maintenance: The installation of power quality monitoring systems can assist in the identification and resolution of problems before they result in the breakdown of the system or damage to the equipment.

Standards and Guidelines for Power Quality

Maintaining adherence to the norms and criteria that have been established for power quality is absolutely necessary in order to guarantee the dependability and effectiveness of electrical systems. For the purpose of successfully managing and mitigating power quality challenges, these standards provide a framework for the design, implementation, and evaluation of power systems.

Overview of Power Quality Standards

Standards for power quality are produced by international and national agencies in order to specify the permissible limits for a variety of power quality metrics and to detail the best practices for sustaining those standards. The observance of these standards guarantees compatibility and dependability across a variety of geographical areas and computer platforms.

Key Standards and Guidelines

IEEE Standards:

IEEE, which stands for the Institute of Electrical and Electronics Engineers, is a professional organization that is committed to promoting technology for the betterment of humanity. It is one of the largest technical professional organizations in the world, having been established in 1963. Its members include scientists, engineers, and other professionals who work in the fields of electrical engineering, electronics, computer science, and other related fields.

- IEEE 519: This is one of the standards that is referred to the most frequently all around the world for power quality. In order to reduce the negative influence that harmonic voltage and current levels have on the system, it provides guidelines for harmonic control in electrical power systems. These guidelines set limitations for the levels of harmonic voltage and current.

- IEEE 1159: This standard, known as IEEE 1159, is a classification system that classifies power quality issues and provides a framework for monitoring these disturbances. At the same time, it functions as an essential guide for evaluating and analyzing power quality.

IEC Standards:

The International Electrotechnical Commission (IEC) is a worldwide organization that is responsible for the preparation and publication of international standards for all the technologies that are associated with electrical and electronic applications. It was established in 1906 and is now considered to be one of the most influential standards organizations in the world. It plays a significant part in guaranteeing the safety, dependability, and interoperability of electrical and electronic equipment and systems.

- IEC 61000: The International Electrotechnical Commission (IEC) 61000 series encompasses a wide range of topics related to electromagnetic compatibility (EMC) and power quality. These topics include emission, immunity, and testing and measuring methodologies. With this knowledge, one may better comprehend the ways in which electronic equipment can influence the electrical network and vice versa.

- IEC 62040: With a particular emphasis on uninterruptible power systems (UPS), the International Electrotechnical Commission (IEC) 62040 is a standard that outlines the requirements for performance and testing. This standard ensures that UPS systems offer dependable and consistent protection against power interruptions.

EN 50160: A European standard known as EN 50160 is responsible for defining the voltage characteristics of the electricity that is supplied by public distribution systems. It establishes standards for a variety of factors, including harmonic voltage levels, frequency, symmetry of the three-phase supply, and voltage levels, among others.

Importance of Compliance

System Compatibility and Interoperability: Compliance with international and national standards guarantees that equipment created in one region of the world may function safely and effectively in another region, which in turn facilitates global trade and interoperability.

Enhanced System Reliability: Increased System Reliability Standards are helpful in developing systems that are resistant to a variety of disruptions, which ultimately results in an increase in the overall reliability and efficiency of power networks for the entire system.

Legal and Regulatory Compliance: The observance of power quality standards is not only a technical necessity in many areas, but it is also a legal obligation. This is because of the legal and regulatory compliance implications. It is possible to incur penalties, legal complications, and significant damage to one's reputation if one does not comply.

Implementing Power Quality Standards

Design and Planning: During the design and planning stages of electrical installations, engineers are required to consider certain standards in order to guarantee compatibility and compliance from the very beginning of the process.

Monitoring and Control: It is essential to perform continuous monitoring of power quality indicators in order to ensure that standards are maintained. Data on a variety of power quality indices can be obtained in real time through the utilization of advanced metering infrastructure and power quality analyzers.

Regular Audits and Assessments: Regular audits and evaluations carried out by experienced personnel help to assure continuing compliance with power quality requirements and permit prompt changes to emerging difficulties.

直接登录

创建新帐号