Introduction

Challenges in Battery-powered Devices

Our daily lives are now dominated by battery-powered gadgets, from smartphones and wearable tech to distant sensors and medical implants. Despite technological progress, developing battery-powered gadgets still poses a number of difficulties:

Energy Constraints: The amount of power the gadget can use is limited by the battery capacity. Designers must weigh the trade-offs between performance and energy usage in light of this limitation.

Size and Weight Limitations: Devices that run on batteries are frequently designed to be portable. As a result, the battery's capacity for energy is constrained in terms of size and weight.

Heat Dissipation: Since these devices are frequently small, effective heat dissipation becomes difficult. Overheating can compromise the dependability and durability of batteries.

Cost Considerations: The price of the gadget must be kept under control for it to be economically viable. This restricts the battery capacity and feature possibilities.

Battery Maintenance and Replacement: Battery changes on a regular basis might not be viable depending on the use case. Battery life duration must be taken into account during design, as well as potential energy harvesting techniques.

Significance Of Low Power Consumption In ADCs

Battery-powered devices require analog to digital converters (ADCs) to connect the analog and digital worlds. ADCs are essential in applications including sensor data collecting, audio processing, and medical signal monitoring.

Extended Battery Life: Low-power ADCs use less power during each conversion. Longer battery life is the result, which is quite desirable for portable devices.

Heat Reduction: Less heat is produced when less electricity is used. This can help with some of the issues with tiny devices' heat dissipation.

Smaller Battery Requirements: Smaller batteries can be utilized with decreased power consumption without reducing the device's operating lifespan. Additionally, by doing this, the gadget may become lighter and more compact.

Increased Device Reliability: Power-efficient components often operate at lower temperatures, extending the device's lifespan and increasing dependability.

Environmental and Economic Impact: The use of smaller batteries and extended battery life not only provide financial advantages but also lessen environmental effects by reducing battery waste.

Application Requirements

Application Requirements

Before choosing an ADC for a battery-powered application, take into account some of the application requirements. Select an ADC that maximizes for each of the aforementioned application criteria.

Power Sensitivity: The gadget will be power-sensitive, which means that its performance, lifespan, or usefulness will all be significantly impacted by its power usage.

Analog Input Sources: A need for digital processing or analysis due to the presence of analog input sources, such as sensors, audio inputs, or other signals.

Data Conversion Rate: Think about how quickly analog data must be translated to digital. If the application does not require high-speed data conversion, a low-power ADC is advantageous.

Resolution Requirements: Take into account the application's resolution specifications. A low-power ADC with modest resolution may be adequate if great accuracy is not essential.

Portability and Form Factor: The benefits of reduced power consumption will be more noticeable since the device will be portable or have size and weight restrictions.

Operating Environment: In distant areas where battery replacement is problematic or in settings where power economy is essential, take into account the environment in which the device will be used.

Cost Sensitivity: The application will be price-sensitive, and a decrease in power consumption will result in cost savings, either through a reduction in the amount of battery power needed or a decrease in running expenses.

Application: Portable Environmental Monitoring System

Consider the installation of a SAR ADC in the context of a portable environmental monitoring system.

Low Power Consumption: Environmental monitoring devices are frequently installed in isolated areas without easy access to power sources. By using a low-power ADC, the system may run for longer periods of time on battery power, lowering the need for battery changes.

Low Data Conversion Rates: Temperature, humidity, and air quality are examples of environmental variables that often fluctuate gradually. Because high-speed data conversion is not necessary, the low-power ADC is a good option.

Moderate Resolution Requirements: Ultra-high accuracy is not always necessary for environmental monitoring. Temperature, humidity, and other parameters may be measured with adequate accuracy using a low-power ADC with a modest resolution.

Portability: Systems for monitoring the environment must be portable and light, especially for investigations that call for movement. Smaller batteries may be used because of the ADC's high power efficiency, which can greatly lighten and make the system compact.

Cost-Effectiveness: Lower operational expenses are a result of the decreased power use. Due to its possible reduced cost and lesser battery needs, using a low-power ADC will also result in improved cost effectiveness.

ADC Selection

Power efficiency becomes crucial when constructing a battery-powered gadget when choosing the right ADC. To prolong the battery life, the ADC's power consumption should be kept as low as feasible.

Potential ADCs for Battery-Powered Devices

Power efficiency is essential in battery-powered apps to increase the device's battery life. Due to their low power requirements and great energy efficiency, several types of ADCs are appropriate for certain applications. ADCs that are frequently seen in battery-operated devices include the following:

Sigma-Delta ADCs: Sigma-Delta (ΣΔ) ADCs are renowned for their high resolution and good noise performance. Due to their use of oversampling and noise shaping techniques, which enable them to achieve high resolution with relatively slow analog components, they are very energy-efficient. In battery-powered systems where accuracy and power economy are crucial, such as portable medical instruments and energy monitoring devices, Sigma-Delta ADCs are frequently utilized.

Successive Approximation Register (SAR) ADCs: SAR ADCs are renowned for their ease of use and low power requirements. They generally have a modest resolution and decide the digital output using a binary search technique. Applications requiring excellent precision, moderate conversion speeds, and low power operation are well suited for SAR ADCs. They are often found in consumer electronics, industrial sensors, and Internet of Things (IoT) gadgets that run on batteries.

Selecting a SAR ADC for Low Power Applications

Due to a number of significant benefits that meet the needs of battery-powered applications, a Successive Approximation Register (SAR) ADC is an appropriate option. The following justifies choosing a SAR ADC for battery-powered applications:

Low Power Consumption: Compared to other high-speed ADC designs like Flash ADCs or pipeline ADCs, SAR ADCs are renowned for using less power.

Moderate Speed and High Accuracy: For battery-powered applications that don't require quick and continuous data collecting, SAR ADCs' modest conversion rates are frequently sufficient.

Simple Architecture: Compared to certain other ADC kinds, the SAR ADC's design is more simple and requires less components.

Power-Down Capability: In order to save even more energy while not actively converting, SAR ADCs may be effectively put into power-down mode in between conversions. In battery-powered applications, where power-saving modes are essential to prolong battery life, this functionality is quite helpful.

Flexibility and Compatibility: SAR ADCs come in a variety of resolutions, designers may choose the ideal bit depth to satisfy the application's accuracy needs without adding needless power overhead.

Suitable for Low to Moderate Sampling Rates: Since high-speed conversions have the potential to use more power, battery-powered applications frequently operate at lower sample rates. SAR ADCs are excellent for a variety of data gathering applications in battery-powered devices because they perform well at low to moderate sample rates.

Portable medical equipment, Internet of Things sensors, wearable health monitors, remote environmental sensors, and energy-efficient communication devices are a few examples of battery-powered applications that might profit from a SAR ADC.

The SAR ADC is an appealing option for battery-powered applications because of its overall low power consumption, moderate speed, high accuracy, simplicity, and power-down capabilities, which helps to prolong the battery life and increase the device's overall efficiency.

Introduction to SAR ADC

Recap of SAR ADC Architecture

One of the most popular ADC designs is the Successive Approximation Register Analog-to-Digital Converter (SAR ADC), particularly in situations where precision and power efficiency are crucial. Using a binary search technique, the SAR ADC transforms continuous analog signals into discrete digital representations while accurately approximating the analog input value.

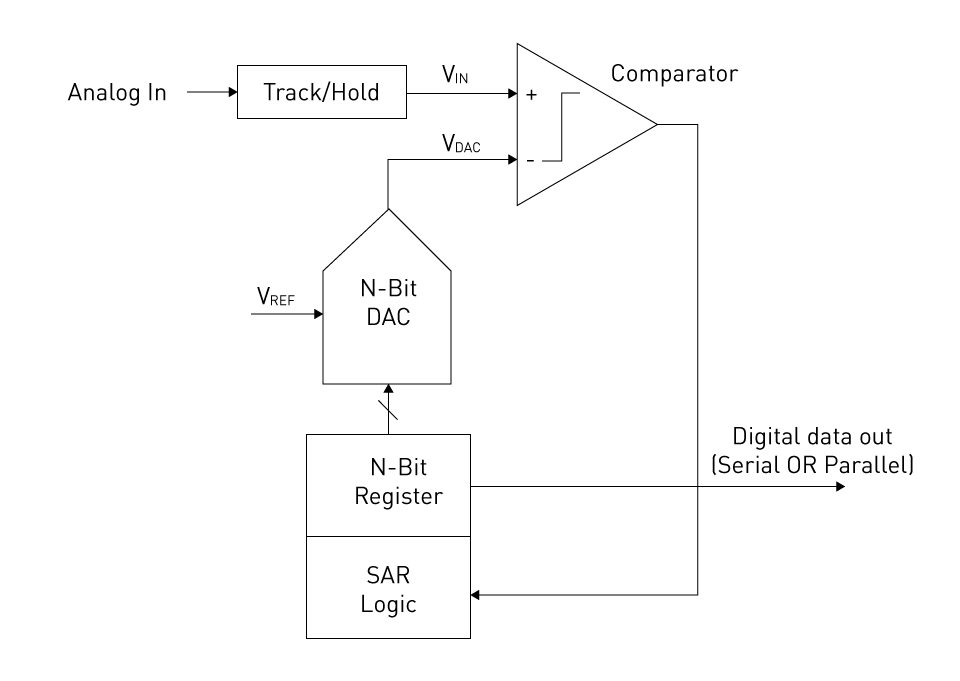

Figure 4: Simplified SAR ADC architecture

SAR ADCs basic elements consist of:

- Sample-and-Hold Circuit: It samples the analog input signal and maintains a steady voltage level throughout the conversion process.

- Successive Approximation Register (SAR): It serves as the central component of the ADC and produces a binary approximation of the input signal.

- DAC (Digital-to-Analog Converter): It transforms the SAR's digital output into an analog value so that it may be compared to the input signal.

- Comparator: It determines whether to set or clear the bit now being chosen by comparing the DAC's output with the input signal.

- Control Logic: It controls all parts of the conversion process, including time.

The most significant bit (MSB) is the first bit the SAR attempts to convert to 1 throughout the conversion process. The comparator then compares this analog value to the sampled input after the DAC has converted it to an analog value. The bit is confirmed to be 1 if the DAC's output is less than or equal to the input; otherwise, it is reset to 0. Once all of the bits have been identified, the SAR moves on to the following one.

Significance of Low Power Consumption

A battery-powered application's value rests in its capacity to function without a permanent power source, making it transportable, flexible, and adaptable in a variety of environments. In the current world, battery-powered gadgets have grown commonplace, enabling a variety of applications like cellphones, wearable technology, medical equipment, remote sensors, Internet of Things devices, and more.

Users benefit from the ease and flexibility that battery-powered gadgets offer by allowing them to be utilized anywhere without the need for a continual external power source. Battery-powered devices are useful for environmental monitoring, data collecting, and communication in difficult conditions since they may be deployed in far-flung or off-grid sites.

These programs frequently optimize power usage to increase battery life, encouraging sustainability and energy efficiency. SAR ADCs are renowned for using less energy than other high-speed ADC designs. The SAR ADC uses a binary search method to operate, which uses very little energy and is ideal for battery-powered devices looking to extend battery life.

Design Process

Specifications

Starting with specifying the specifications, which are motivated by the application requirements, a High-Speed SAR ADC is designed. The key requirements that must be defined are as follows:

Sampling Rate: This essential characteristic for high-speed applications refers to the rate at which the ADC can convert analog signals to digital signals.

Resolution: This specifies how many bits are used in the digital output. The ADC can more accurately reflect the input with a higher resolution.

Power Consumption: Power efficiency is essential for portable devices. To make sure the ADC is appropriate for the application, the maximum power and average power consumption should be specified.

Input Voltage Range: The ADC's ability to handle a variety of analog input voltages.

SNR and SFDR: The quality of the digital output may be assessed using the signal-to-noise ratio and spurious free dynamic range.

Choice of Components

The next step is to choose the parts that will go into the SAR ADC. Included in this is the option of:

Comparators: A fast comparator is necessary. The decision will have an impact on the speed and energy use.

DAC: The SAR architecture depends on the Digital-to-Analog Converter. The ideal DAC is quick and glitch-free.

Sample and Hold Circuit: An accurate input signal capture requires a high-speed sample and hold circuit.

Logic Gates: The control logic requires these gates.

Capacitors and Resistors: These parts are necessary for the DAC and other filtering functions.

Layout and Schematic Design

Schematic design and layout start after component selection. This stage involves:

Creating the Schematic: Using a schematic capture tool, the electrical connections between the components are made in this phase.

PCB Layout Design: To do this, the electrical connections must be routed and the components must be mounted on a PCB. To cut down on parasitics and ensure adequate grounding, essential paths should be kept as short as possible.

Simulations: At this stage, running simulations can assist in confirming the behavior of the design.

Design Verification and Testing

Verifying and testing the SAR ADC design is the last step in the design process. This is accomplished by:

Prototype Fabrication: Fabricating a prototype PCB with the intended SAR ADC.

Functional Testing: The ADC is put through fundamental functional tests to make sure it is operating as it should.

Performance Testing: The Total Harmonic Distortion (THD), Effective Number of Bits (ENOB), SNR, and SFDR are measured as part of stringent performance assessments.

Environmental Testing: To make sure that the ADC can function dependably in its intended use, this requires testing it under a variety of environmental conditions, including temperature and humidity.

Iterative Optimization: The design may need to be altered and optimized based on the testing results. This could entail altering the control logic, the PCB routing, or the components.

An intricate and iterative process, the design of a High-Speed SAR ADC necessitates a thorough comprehension of both the theoretical and practical aspects of ADCs as well as the particular requirements of the desired application.

Implementation and Integration

Embedding SAR ADC in System Design

The SAR ADC design will then be embedded into the target system after undergoing verification and testing. The integration procedure incorporates the following factors:

Interface with Microcontroller or Processor: The microcontroller or CPU of the system must interface with the SAR ADC. Configuring SPI, I2C, or another communication protocol is frequently required for this.

Analog Input Conditioning: The SAR ADC's analog input must be appropriately conditioned in order to function. In order to scale or amplify the input signals to fit the ADC's input range, noise may be removed by filtering.

Power Supply Design: Powering the ADC should be pure and reliable. This can entail filtering noise with bypass capacitors and a separate voltage regulator.

Software Integration: To properly configure the ADC and read the data, the system software must be created or altered. This can entail creating algorithms to process the digital output from the ADC and writing driver code.

System-Level Verification

It's critical to confirm that the SAR ADC functions as expected within the context of the overall system after integration:

Functional Verification: Make that the ADC can transform data, transport it, and interact effectively with the microcontroller or CPU.

Performance Verification: Analyze the ADC's performance in relation to the entire system. This entails considering variables like SNR, SFDR, and ENOB in the context of the overall performance of the system.

End-to-End Testing: Test the entire system under situations that closely mimic the actual usage scenarios. This requires evaluating the ADC as a component of the entire signal chain of the system.

Optimization for Performance

It may be necessary to optimize the SAR ADC and the system for performance after system-level verification.

Tuning ADC Settings: This may entail changing the ADC's sampling rate, resolution, or input range settings to improve its performance for the particular application.

Power Optimization: Optimizing the ADC and system for low power consumption is frequently crucial for battery-powered applications. Techniques could involve using sleep modes or dynamically altering the ADC's sampling rate.

Noise Reduction: It could be necessary to include extra filtering or shielding to lower the noise detected by the ADC.

Software Algorithm Optimization: To achieve the necessary system performance, advanced algorithms for processing ADC data may need to be optimized or developed.

Testing and Verification for Low Power Consumption

It is crucial to confirm that the circuit performs in accordance with your design parameters after it has been created and constructed:

Measure Power Consumption: Utilize equipment to gauge your ADC's power usage in different working modes. Make sure it complies with your criteria and the specs.

Functional Testing: Make that the ADC is operating properly. Make sure it can transform signals accurately and quickly enough for your needs.

Long-term Battery Testing: Test the battery power over an extended period of time to find any problems that might develop.

You may extend the battery life of your device while ensuring that the ADC performance matches your needs by carefully choosing an ADC, adopting power management techniques, and checking your circuit design.

Results and Analysis

Measurement of Power Consumption

After implementation, it is critical to gauge the system's power usage. The current drawn by the ADC and other components can be monitored in real-time using current measuring instruments or power analyzers. Engineers can comprehend how the ADC uses power in various operating modes by examining the power profile. The method of measuring power consumption is iterative. The gadget operates at the lowest power consumption while maintaining performance thanks to the aid of optimizing the power management techniques that were initially specified.

Evaluation of Battery Life and Performance

Power consumption information allows for the evaluation of battery life. How long the gadget will operate before the battery needs to be recharged or replaced depends on the power profile and battery capacity. Engineers can also determine whether a device satisfies performance requirements by assessing the ADC's performance in terms of resolution, conversion speed, and accuracy. It's critical to assess the ADC's performance at various battery levels because it may alter as the battery's voltage fluctuates.

Tradeoffs and Limitations

There are inherent trade-offs and restrictions in the design of battery-powered devices with low-power ADCs:

Resolution vs. Power Consumption: Higher resolution ADCs frequently use more power. Resolution and power consumption may need to be traded off, depending on the application.

Sampling Rate vs. Power Consumption: Similar to high resolution, increased sample rates frequently result in increased power usage.

Complexity vs. Battery Life: Extending battery life through the use of advanced power management techniques may complicate the design.

Cost Constraints: Finding a balance between cost and power consumption may be necessary in some cases because lower power components can be more expensive.

Recommendations for Energy Efficiency Improvements

Several suggestions for enhancing energy efficiency can be made in light of the findings and analysis:

Use of More Efficient ADCs: ADCs that are more effective could become available as technology develops. Significant increases in energy efficiency might result from routinely reevaluating the market for new and improved components.

Optimization of Firmware: The firmware can be improved to execute ADC readings more effectively and to make greater use of low-power modes.

Improving Power Management Circuits: The overall power usage can be decreased by using more effective voltage regulators or energy harvesting methods.

直接登录

创建新帐号