Advances in Isolation Materials

The evolution of isolation materials in the electronic design of digital isolators is a field that is characterized by continual innovation, which has led to considerable gains in both performance and reliability. In contemporary electronics, one of the most important areas of focus is the investigation of novel materials and their effects.

Exploration of Novel Materials

New Dielectric Materials: Recent developments have been made in the creation of new dielectric materials that have greater breakdown voltages and lower leakage currents. These new dielectric materials have gained popularity in recent years. The insulating qualities of these materials are significantly increased, which is an essential quality for applications involving high voltage isolation.

Polymer Innovations: Now, work is being done to make new polymers that have better chemical resistance, breakdown strength, thermal and mechanical stability, electrostatic discharge (ESD) performance, and lower permittivity. The fact that these materials are able to survive tough climatic conditions makes them an excellent choice for applications in the automotive and industrial sectors.

Eco-Friendly and Sustainable Materials: There is a rising emphasis on the utilization of materials that are not only high-performing but also can be considered environmentally sustainable. Isolation materials that are both biodegradable and recyclable are becoming increasingly the subject of research.

Impact of Material Advances on Performance and Reliability

Enhanced Electrical Performance: Innovative isolation materials contribute to increased insulation resistance and lower capacitive coupling, which ultimately results in improved electrical performance. This enables the materials to contribute to improved electrical performance. Especially in applications where signal integrity and noise reduction are of the utmost importance, this increase is absolutely necessary.

Increased Thermal Stability: Better materials enable isolators to function over a larger temperature range without degrading. This results in increased thermal stability. When it comes to reliability, this thermal stability is absolutely necessary, particularly in applications that are subjected to extremely high temperatures.

Longevity and Durability: Developments in material science improve the endurance and durability of isolation components, contributing to the overall advancements in the field. When it comes to maintenance and replacement, materials that are resistant to wear, corrosion, and environmental variables eliminate the need for frequent replacements and repairs.

Customization for Specific Applications: The creation of novel materials makes it possible to personalize the isolation qualities of the material in order to meet the requirements of particular applications. To achieve the desired level of performance, adjust the dielectric constants, breakdown voltages, and thermal conductivities.

Integration Technologies

The invention and refinement of integration technologies in electronic design have been crucial in driving the evolution of modern electronics. These technological breakthroughs are not merely technical achievements; rather, they have a significant impact on the dimensions, costs, and power consumption of electronic gadgets.

Development in Integration Methods

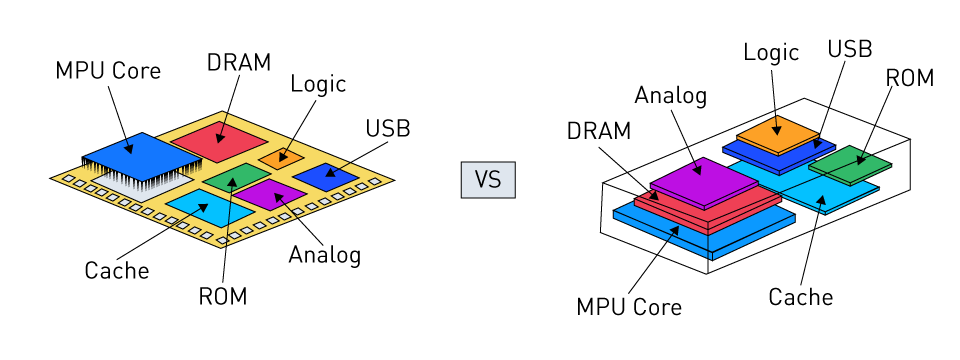

System-on-Chip (SoC) and System-in-Package (SiP): The terms "system-on-chip" (SoC) and "system-in-package" (SiP) refer to two technologies that have made significant advancements in the field of integration technology. In contrast to single-chip packages (SiPs), which include several chip components within a single package, system-on-chips (SoCs) incorporate multiple CPU cores, memory, and input/output controls onto a single chip. This integration streamlines the production process and enables more compact and efficient designs.

Figure 1: SoC vs. SiP

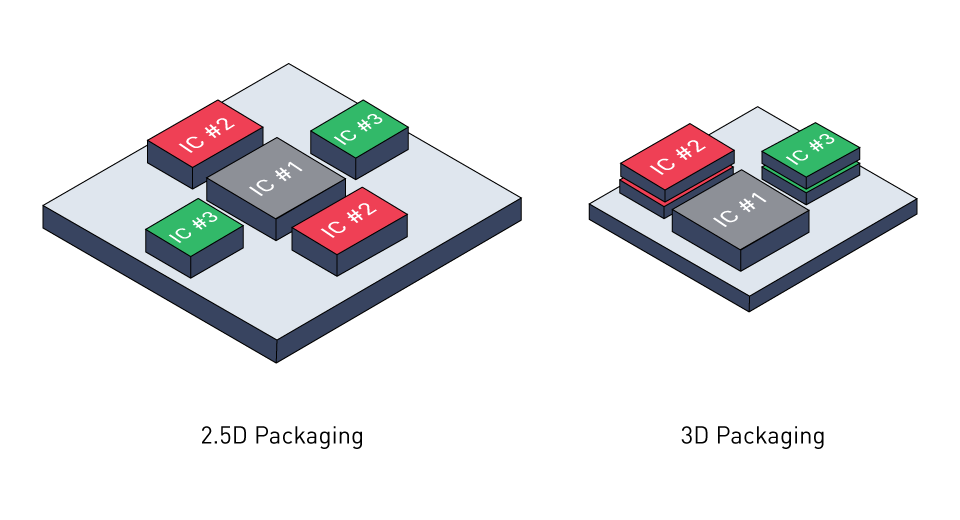

3D Integration and Stacking: The introduction of three-dimensional integration and vertical stacking of semiconductor devices has made it possible to achieve higher component densities. Because of this technology, integrated circuits (ICs) can be stacked one on top of the other, which results in significant space savings and the possibility of performance improvements due to shorter connecting distances.

Figure 2: 3D Integration

Advanced Interconnect Technologies: Recent advancements in connection technologies, such as through-silicon vias (TSVs) and sophisticated packaging techniques, have made it possible for integrated components to communicate with one another in a more effective manner. These advancements enhance the system's overall performance by reducing signal latency and power consumption. Flexible and Printed Electronics: The increased availability of flexible and printed electronics has made new integration opportunities available. The insertion of electrical components onto flexible substrates is made possible by these technologies, which in turn leads to the development of creative applications in the fields of wearable gadgets and flexible displays.

Effects of Integration on Size, Cost, and Efficiency

Size Reduction: Miniaturization of electrical devices is made possible by integration technologies, which allow for significant size reduction. It is possible to greatly reduce the overall footprint of devices by merging many functions into a single module. This allows for the development of devices that are smaller and more portable.

Cost Savings: A higher level of integration typically results in cost savings in both the production process and the utilization of materials. With fewer individual components, it is possible to cut down on the amount of time needed for assembly as well as the costs of production, which is beneficial to both the producers and the customers.

Increased Efficiency: In general, integrated solutions provide a higher level of efficiency. The decrease in the lengths of the interconnects and the optimization of the positioning of the components both result in a lowering of the power consumption and a faster processing of the signals. This efficiency is critical for battery-powered gadgets, which are required to conserve power in order to function properly.

Design Simplification: Integration simplifies the design process because it eliminates the need for designers to handle a large number of independent components. This simplification can speed up both the design cycle and the time it takes to bring new items to market.

Thermal Management Challenges: Despite the fact that this provides a multitude of advantages, it presents obstacles in terms of thermal management. By increasing the density of components, it is possible to get higher heat concentrations, which in turn requires the development of creative cooling methods.

Advancements in Isolation Techniques

Electrical isolation has seen a number of notable breakthroughs, particularly in the fields of capacitive, inductive, and optical isolation. These developments not only improve the efficacy of isolation technologies, but they also broaden their use in a variety of industries.

Innovations in Capacitive, Inductive, and Optical Isolation

Capacitive Isolation Advances: Recent breakthroughs in capacitive isolation include the utilization of sophisticated dielectric materials and microfabrication processes. These innovations are a result of recent advancements in the field. These enhancements have led to the development of capacitive isolators with larger voltage ratings, reduced parasitic capacitance, and enhanced signal integrity. Additionally, we have incorporated digital signal processing techniques to correct for signal distortion. This has resulted in an increase in both the rate of data transmission and its accuracy.

Inductive Isolation Enhancements: In inductive isolation, which is generally accomplished by the utilization of chip-scale micro-transformers, developments include the utilization of advanced insulating materials, downsizing, and an increase in efficiency. As a result of the development of new core materials that have higher permeability and lower losses, it is now possible to create transformers that are more efficient and smaller, making them suited for high-frequency applications.

Optical Isolation Innovations: The advancements in optoelectronics have been beneficial to the development of optical isolation techniques. Optocouplers have seen their performance significantly improved as a result of the utilization of high-efficiency light-emitting diodes and LEDs, in addition to integrated photovoltaic converters. Because of these advancements, response times have become significantly faster, power consumption has decreased, and isolation voltages have skyrocketed. Integration with silicon photonics is a developing field that holds the promise of greater downsizing and improved performance.

Implications for Design and Application

Enhanced Safety and Reliability: As a result of these improvements, isolators are now able to offer improved protection against excessive voltages and electrical noise, hence improving the safety and dependability of electronic systems. The importance of this cannot be overstated in the context of industrial control systems, medical equipment, and automotive electronics, all of which place a premium on safety.

Increased System Performance: Improved isolator technologies allow for faster data transfer and lower propagation delay and delay skew, which directly impacts the performance of communication systems, data collection systems, and digital interfaces. This results in an increase in system performance.

Miniaturization and Integration: The development of isolation technologies has provided support for the trend toward downsizing and integration in electrical design. Downsizing and integration are two terms that are becoming increasingly popular. It is because of this that it is possible to build solutions that are more compact and integrated, which is especially helpful in applications that are portable and have limited space.

Energy Efficiency: Using isolation techniques that become more efficient over time improves the overall energy efficiency of electronic systems. This is of the utmost importance in applications that place an emphasis on power conservation as well as in devices that are powered by batteries.

Broader Application Range: Innovations in isolation techniques have resulted in an expansion in the application range of isolators, which has led to a wider range of applications. Isolators of today have improved characteristics that make it possible for them to be utilized in a larger variety of applications. These applications range from high-speed data connections to renewable energy systems.

直接登录

创建新帐号